Coagulation-separation apparatus

A separation device and separation box technology, applied in the directions of sedimentation separation, separation method, and sediment separation by centrifugal force, can solve the problem of low processing efficiency and achieve the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

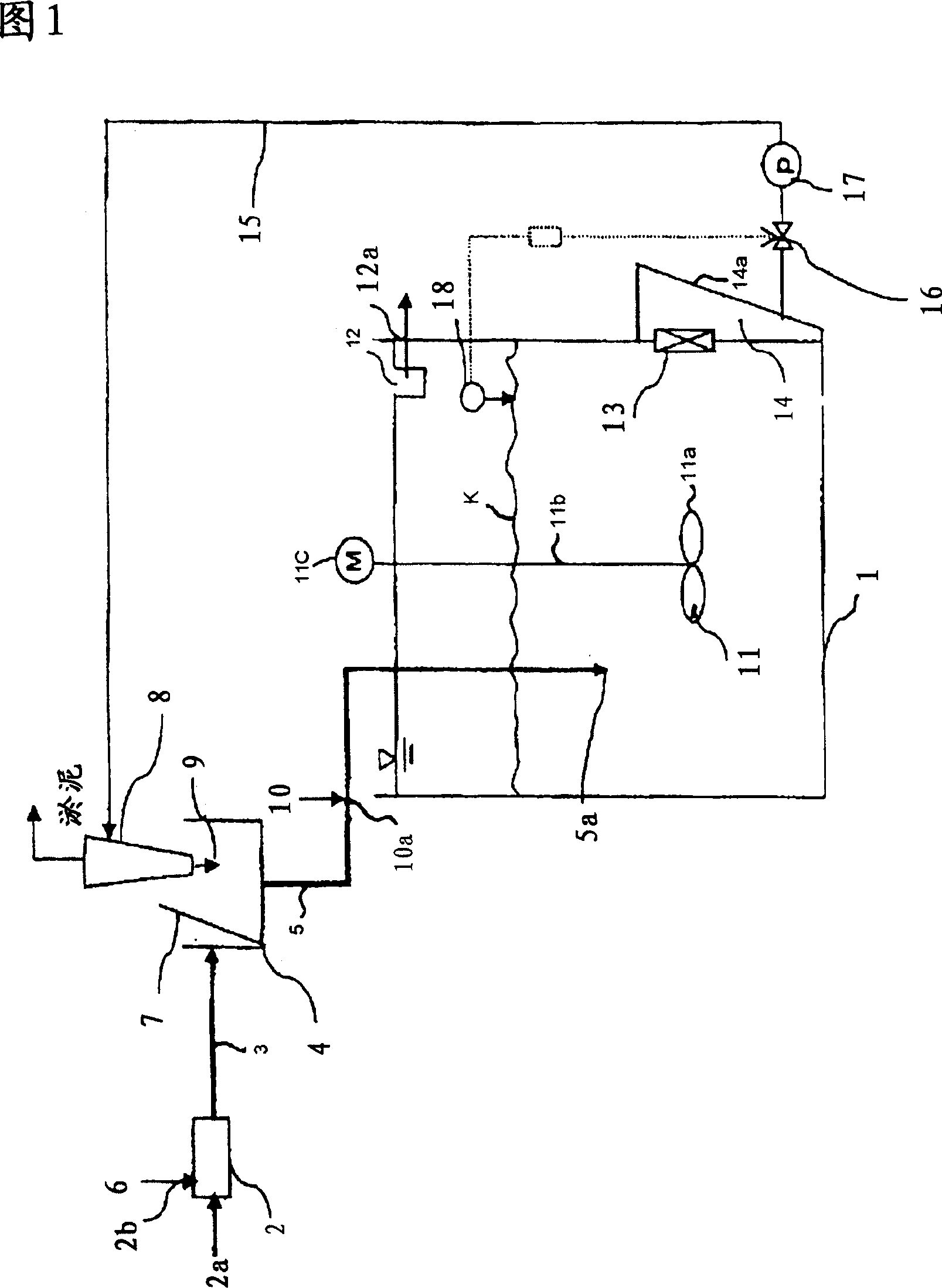

[0094] first instance

[0095] A first embodiment of the coagulation and separation device shown in FIG. 1 was implemented. As a condition of implementation, the inflow water of the first sedimentation tank in the sewage treatment plant is used as raw water. Add PAC to the raw water at an addition rate of 10mg / L (by Al 2 o 3 l conversion) to form a coagulant (inorganic coagulant) 6. Sand was added to the raw water at a concentration of 3000mg / L to form a high specific gravity material9. The polymer coagulant was added to the raw water at a concentration of 1 mg / L to form coagulant aid 10. Under this condition, the results regarding the relationship among influent water volume, residence time in the device, raw water SS, treated water SS, SS removal rate, sludge concentration, and discharged sludge volume were obtained, as shown in Table 1 . As seen from Table 1, the SS removal rate became 80% or higher within 10 minutes of residence time in the apparatus. Therefore, hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com