Semiconductor laser precision tune-up and tempeature control device

A temperature control device and semiconductor technology, applied in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of slow temperature adjustment, low alignment accuracy, low control accuracy, etc., and achieve fast temperature adjustment, stable and reliable performance. , the effect of simplifying the adjustment mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

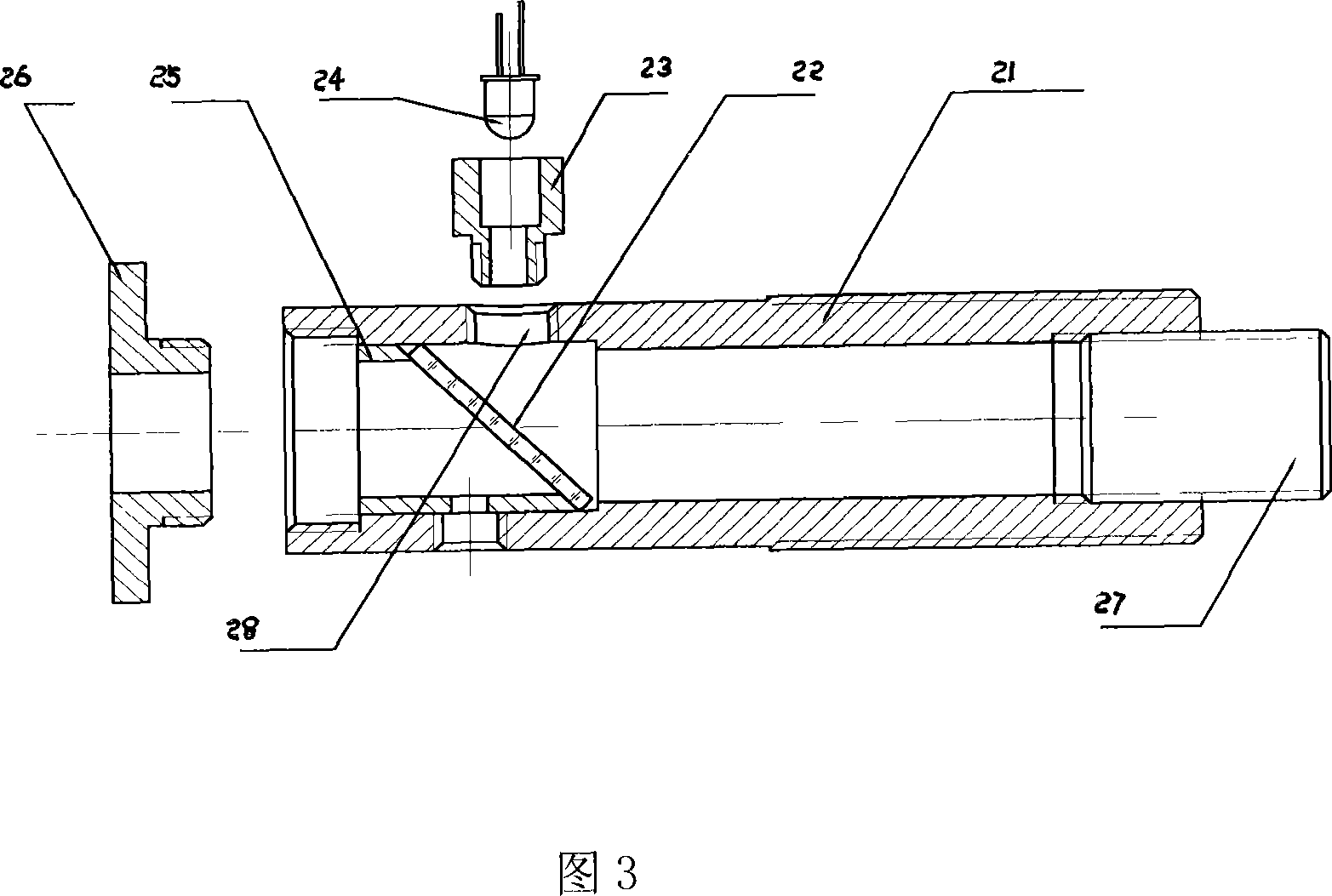

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] This embodiment is composed of a temperature control unit, an adjustment unit, a housing 3 , a base 5 and a joint 6 . Both the temperature control part and the adjustment part are set in the casing 3, the casing 3 is fixed on the base 5, the inner wall of the casing 3 is provided with a heat insulating layer 10, and the bottom of the casing 3 is provided with an L-shaped aviation joint 6 to ensure a compact overall structure . The temperature control part is composed of a laser tube 9, a heat sink 7, a TEC temperature control device 8, and a heat pipe radiator 1. The laser tube 9 is installed on the heat sink 7, the TEC temperature control device 8 is attached to the heat sink 7, and the heat pipe is installed on the back Radiator 1. The alignment part is composed of a beam collimation and photoelectric feedback part 2 and a two-dimensional fine-tuning mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com