All-rotation engine

An engine, full rotation technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of low efficiency, complex structure, unreasonable structural design of rotary engines, etc., to reduce the structure or supporting devices, strokes The effect of long and large output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

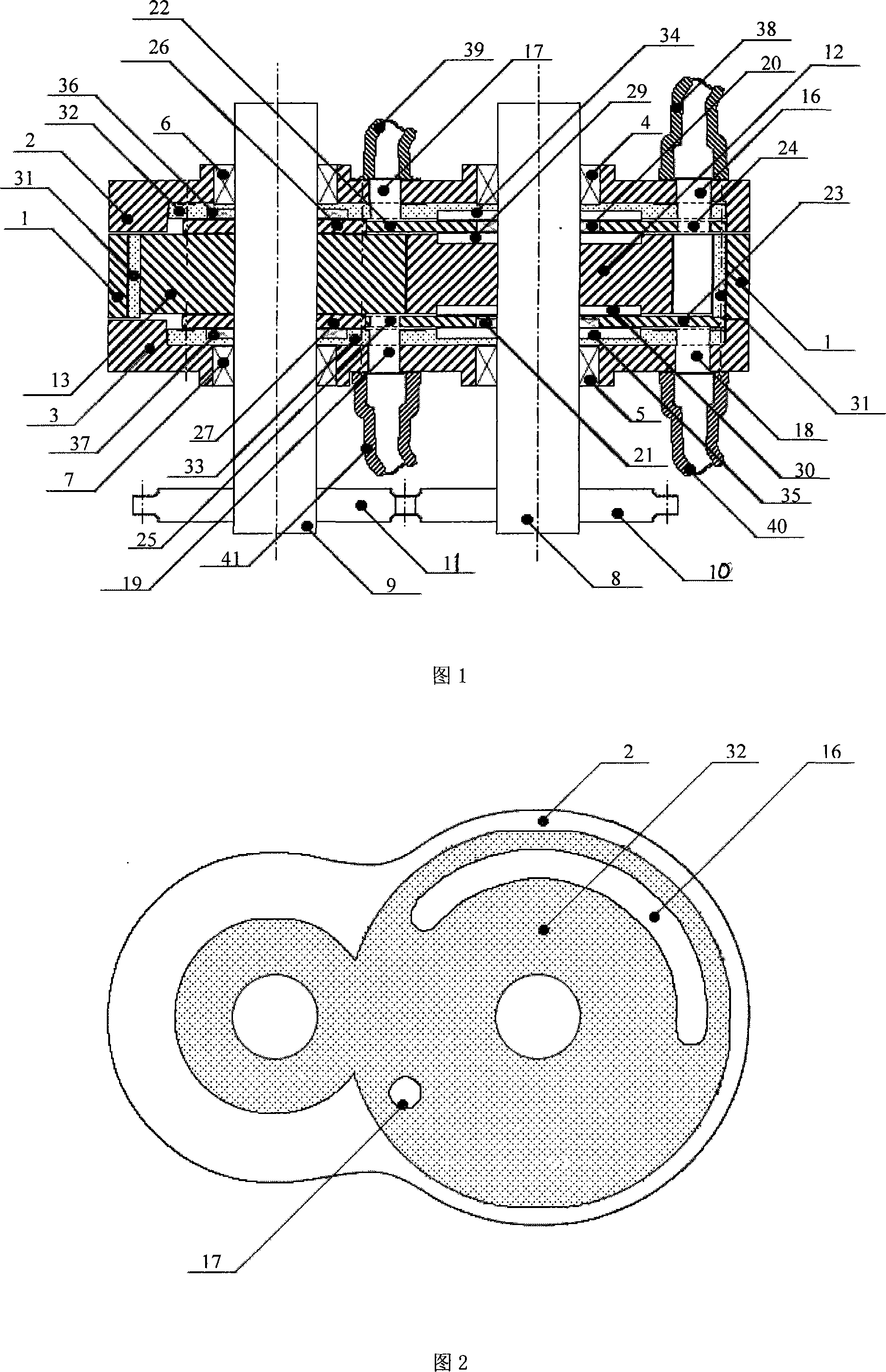

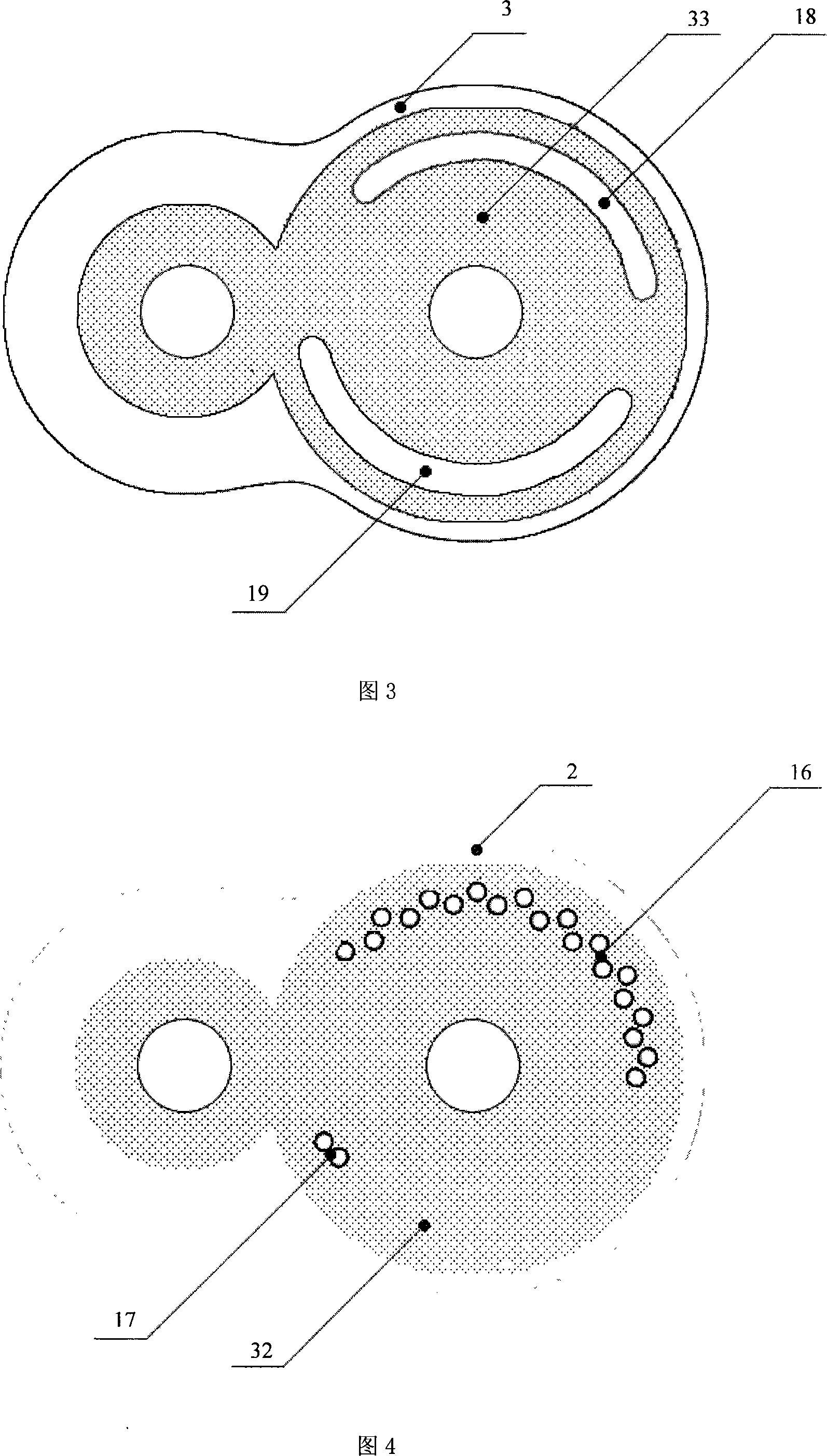

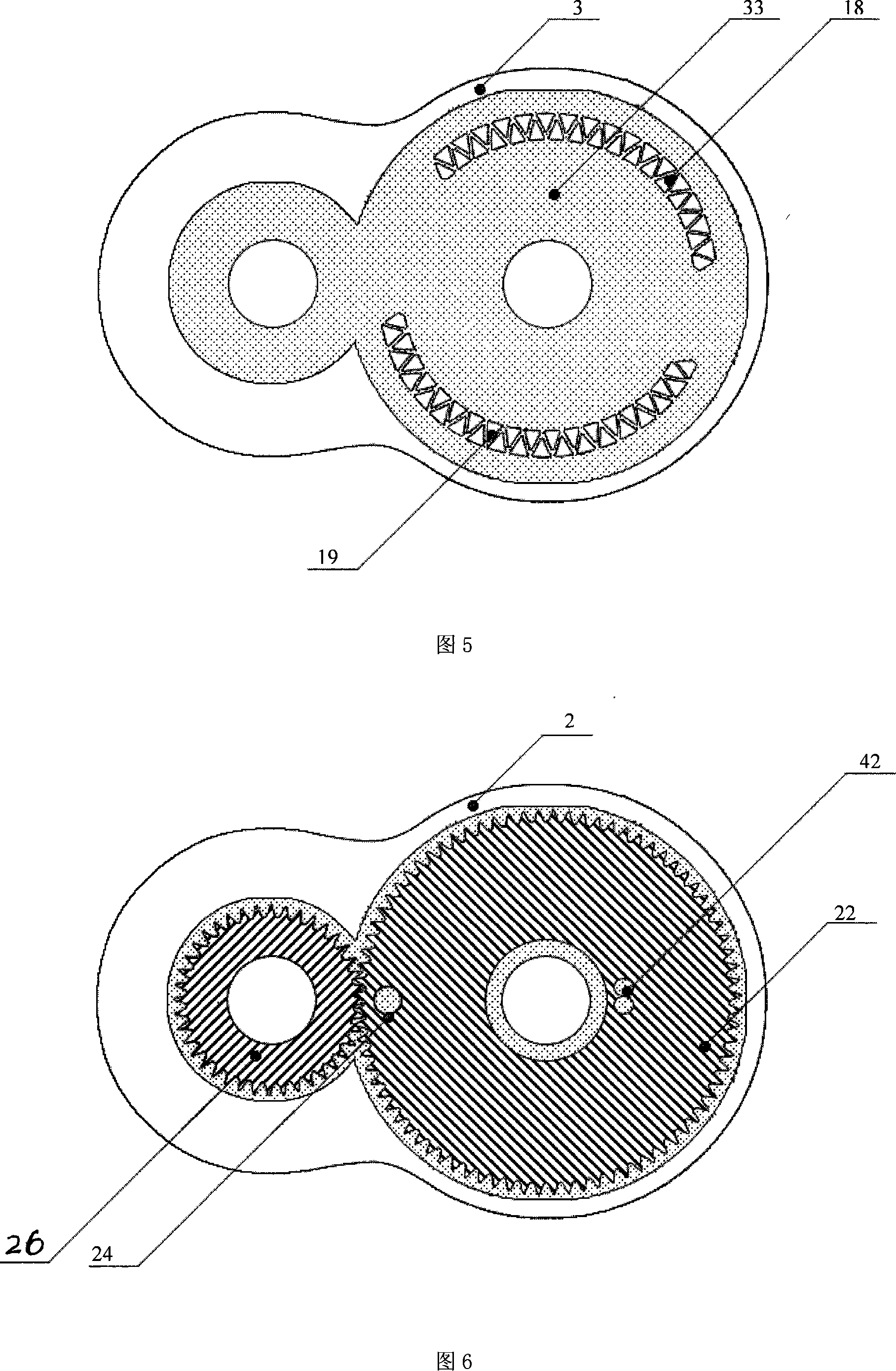

[0026]As shown in Figure 1-Figure 6. The fully rotary engine comprises a cylinder block 1 with two circular cavities and a front cylinder cover 2 and a rear cylinder cover 3 fixed to the cylinder body. The two circular cavity centers of the cylinder block are respectively provided with passing bearings 4, 5, 6, 7 The rotating shafts 8 and 9 supported on the front and rear cylinder heads are respectively fixed with synchronous gears 10 and 11 which mesh with each other and have the same number of teeth at one end of the two rotating shafts; the rotating piston wheel 12 and the rotating sealing wheel are respectively fixed on the two rotating shafts 13. The rotary piston wheel 12 and the rotary sealing wheel 13 are equal-diameter cylinders with airtight rolling contact on the cylindrical surface. The rotary piston wheel 12 is provided with a piston head 14 that is sealingly matched with the inner wall of the circular cavity of the cylinder body. The rotary sealing wheel 13 The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com