Functional liquid coating used for magnesium aluminium alloy base material

A magnesium-aluminum alloy, liquid coating technology, applied in polyester coatings, devices for coating liquid on surfaces, coatings, etc. Coating equipment is not unified, which is not conducive to assembly, etc., to achieve good gloss and color retention, good performance balance, and good interlayer adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

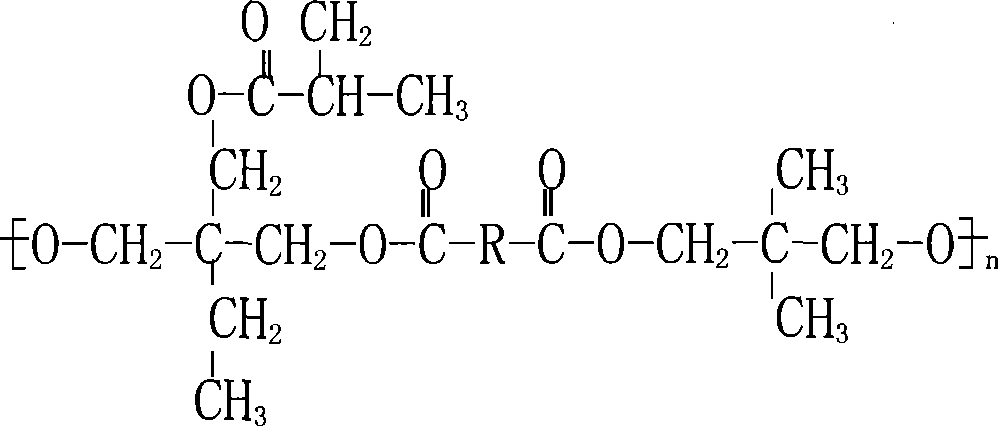

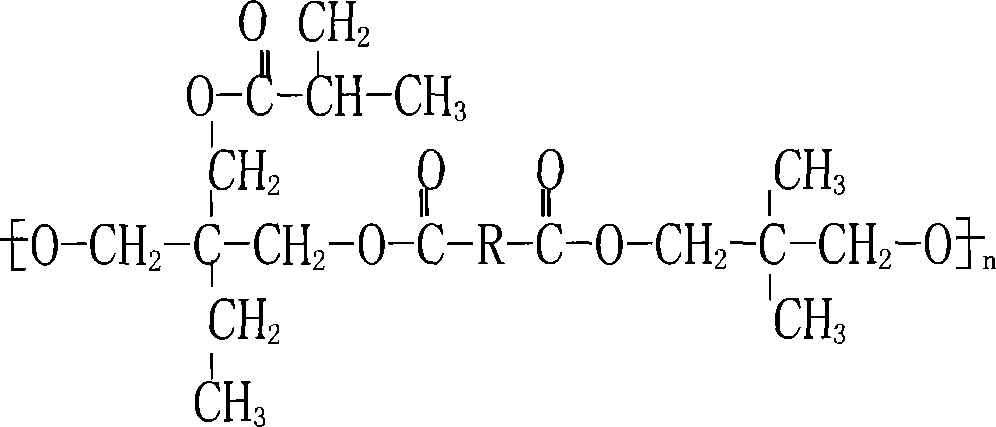

[0017] A functional liquid coating for magnesium-aluminum alloy substrates. It is a matching coating composed of a primer and a topcoat. The raw materials for the primer are weighed according to the following ratio: polyester resin 30, pigments and fillers 30, functional Filler 4, amino resin 20, dispersant 2, leveling agent 0.5, adhesion promoter 3, solvent 10.5; topcoat raw materials are weighed according to the following ratio: polyester resin 35, pigment and filler 15, amino resin 24, dispersion Agent 2, leveling agent 0.7, wear-resistant additive 0.4, adhesion promoter 3, solvent 19.9. Among them, the structure of polyester resin

[0018] The formula is:

[0019] In the formula, R is a hydrocarbon group having 5 or more carbon atoms.

[0020] The imported paint topcoat in the prior art is liquid and the primer is powder, but both the primer and the topcoat of the present invention are liquid, and the interlayer adhesion is good. The fullness and strength of the graft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com