Micro-bearing friction torgue measuring instrument

A technology of friction torque and miniature bearings, which is applied in the field of measuring instruments, can solve the problems of low measurement accuracy of friction torque of miniature bearings, complex mechanical structure, large error of transmission mechanism, etc., to meet the requirements of test accuracy, simple mechanical structure, and eliminate friction Effects of Force and Vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

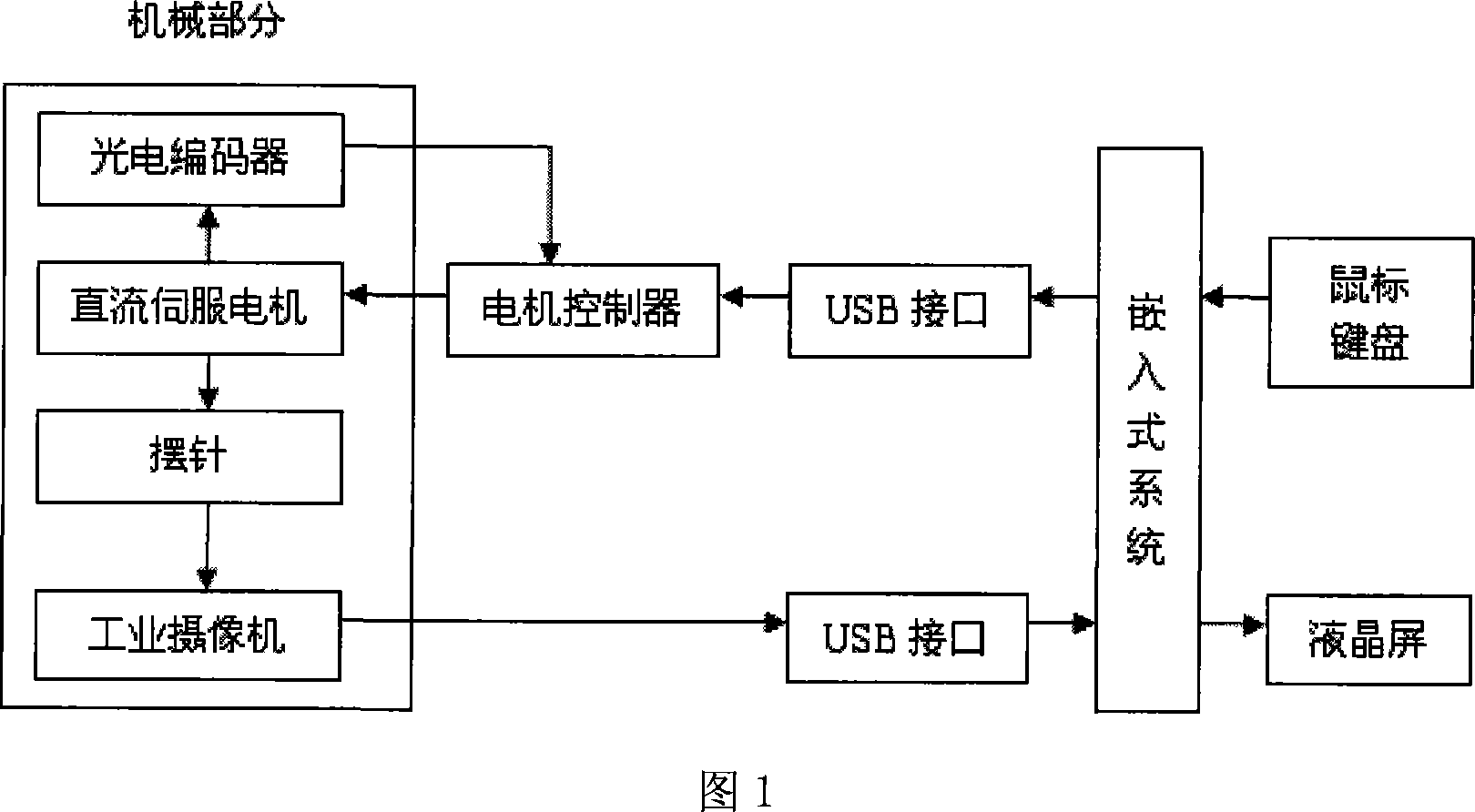

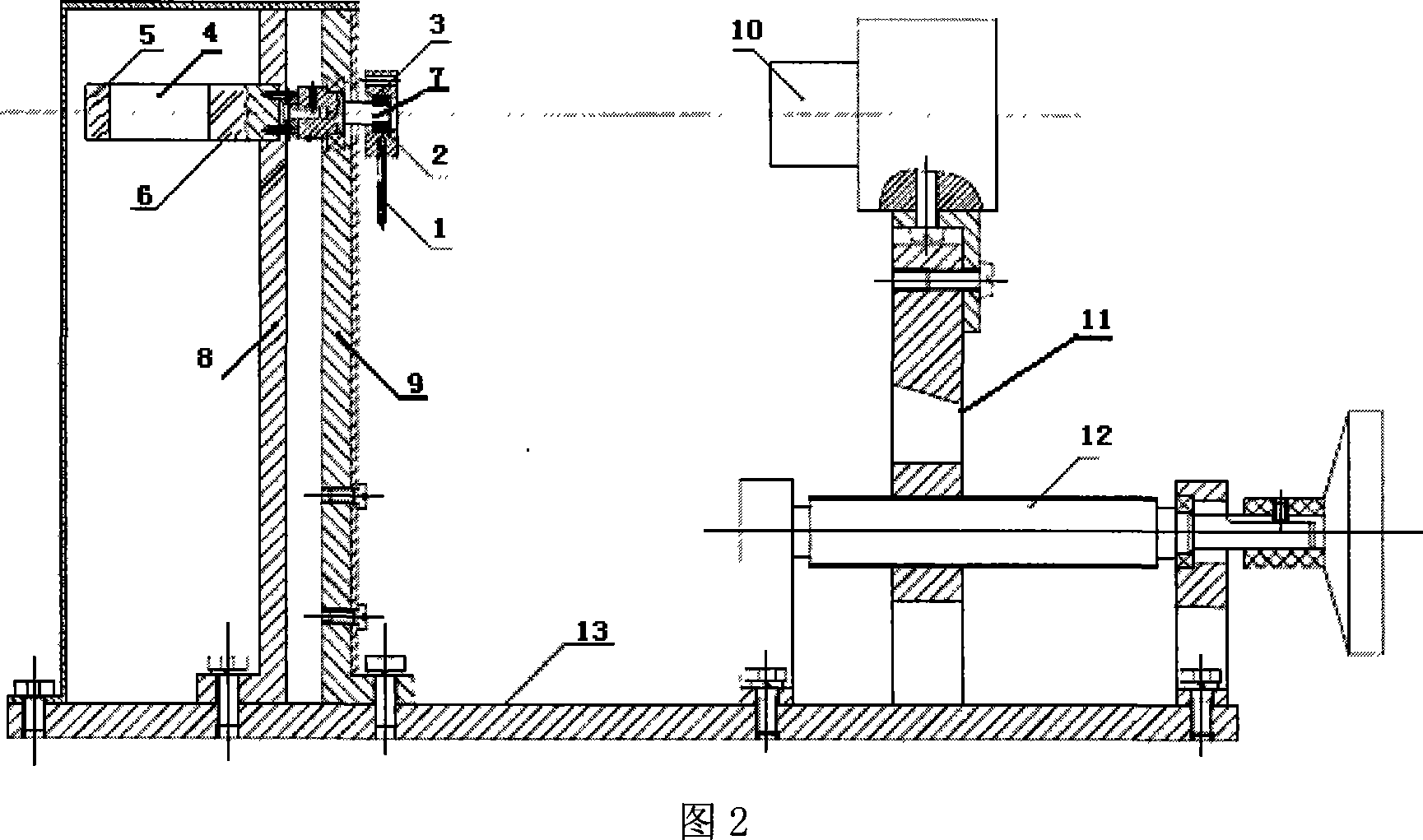

[0026] As shown in Fig. 1 and Fig. 2, the present embodiment includes: a mechanical part, an electrical part and an embedded system, the mechanical part is connected with the input end of the electrical part through a wire and a USB interface, and the input and output terminals of the electrical part are connected with the electrical part through the USB interface respectively. The input and output ends of the embedded system are connected; the mechanical part includes: pendulum needle 1, bearing under test 2, bearing sleeve 3, DC servo motor 4, photoelectric encoder 5, reducer 6, bracket 8 of the DC servo motor syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com