Heat-gathering pot support

A heat collecting pot and hot pot technology, applied in the field of pot support, can solve the problem of high heat loss and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

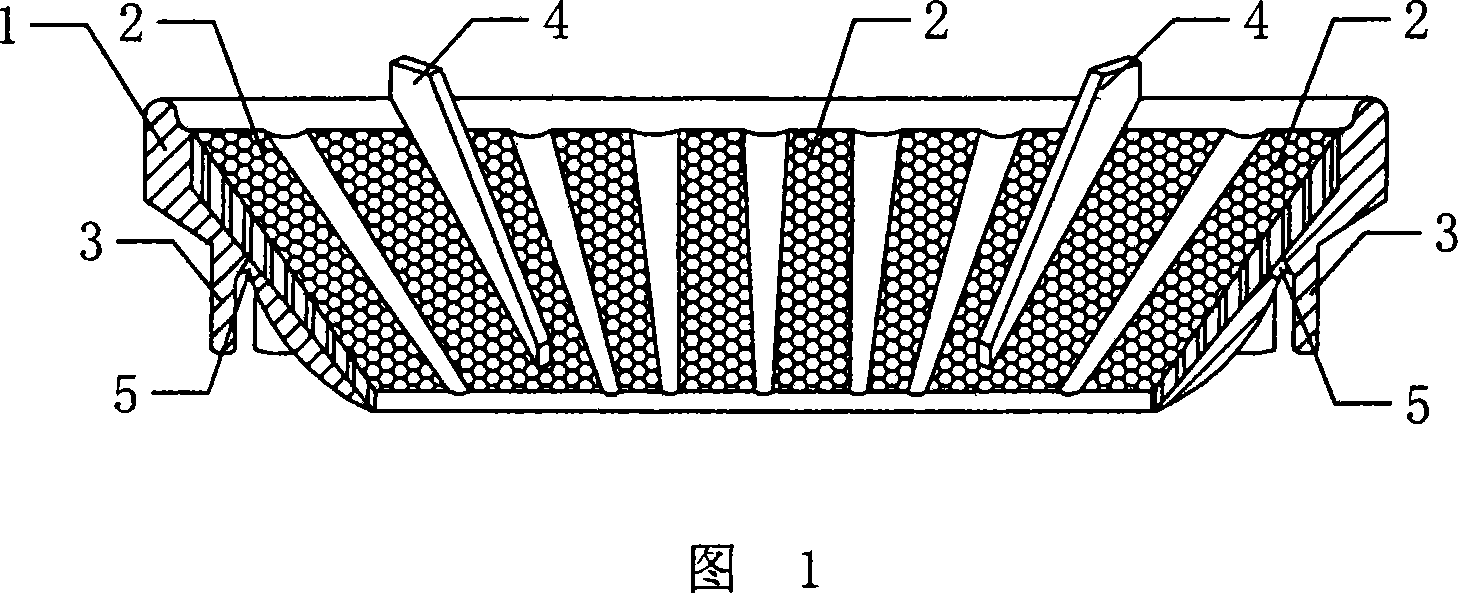

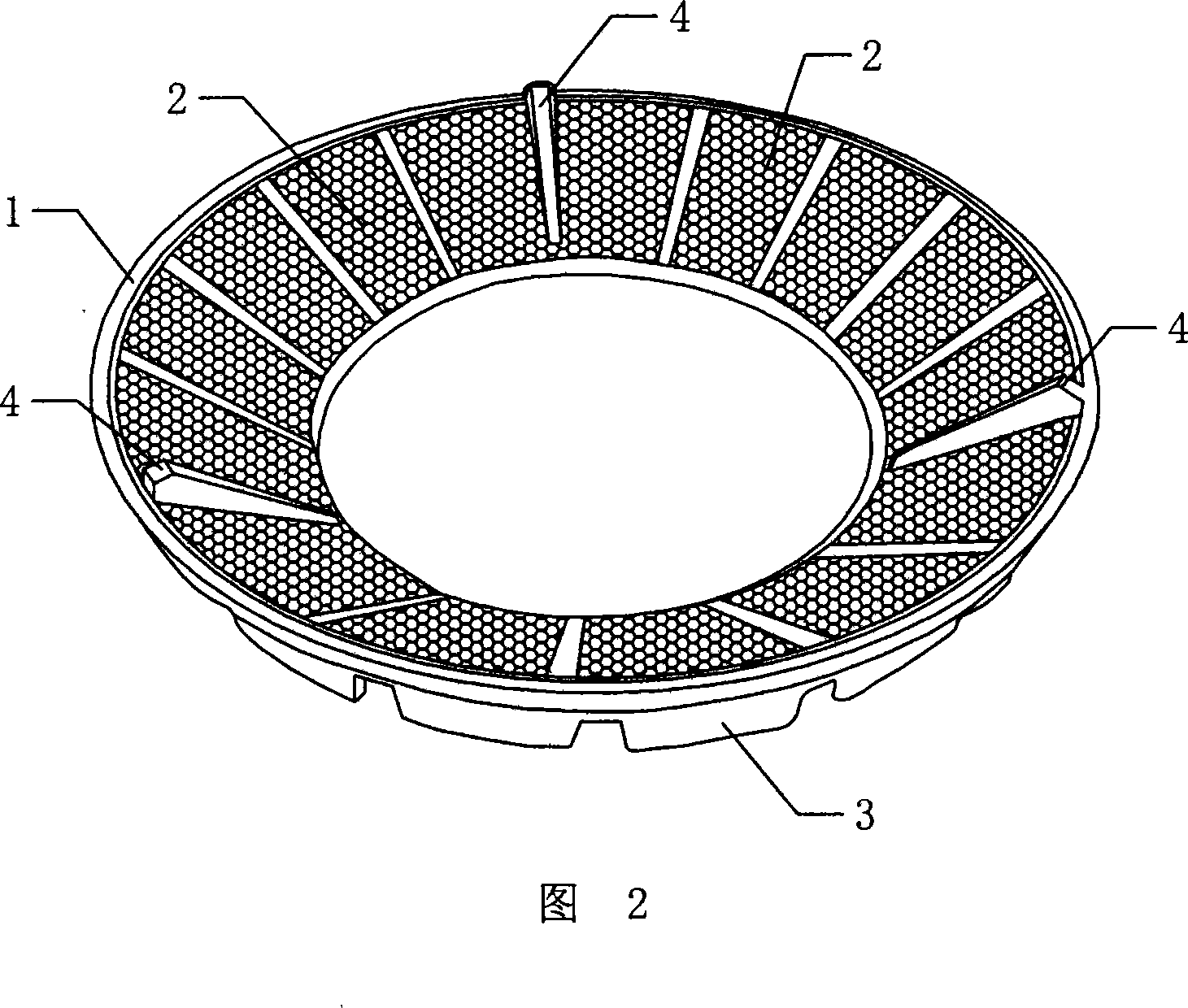

[0011] As shown in Figures 1 and 2, the heat-collecting pot bracket includes a bracket body 1 with an opening corresponding to the furnace head in the middle. The bracket body 1 is ring-shaped, and the outer circumference of the bracket body 1 is fixed with a stable The ring-shaped support foot 3 of the bracket body 1, the ring-shaped support foot 3 is stable and firm to the bracket body 1, and now there is a ring-shaped protrusion on the water tray of the gas stove, and the ring-shaped support foot 3 is installed The bracket body 1 is fixed on the annular protrusion; the bracket body 1 is fixed with three pot bottom supporting claws 4 for supporting the bottom of the pot, and a number of burning flames are installed on the inner side of the bracket body 1 The bottom of the refractory heating plate 2 is covered with through holes, and the surface of the heating plate 2 is provided with concavities and convexities that can reflect the combustion flame and collect it on the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com