Anti-disengaging device for air valve controlling rod

A control rod and valve technology, applied in the direction of valve operation/release device, valve device, valve details, etc., can solve the problems of disengagement, car stop, damage to the engine, etc., and achieve the effect of uniform valve lift and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

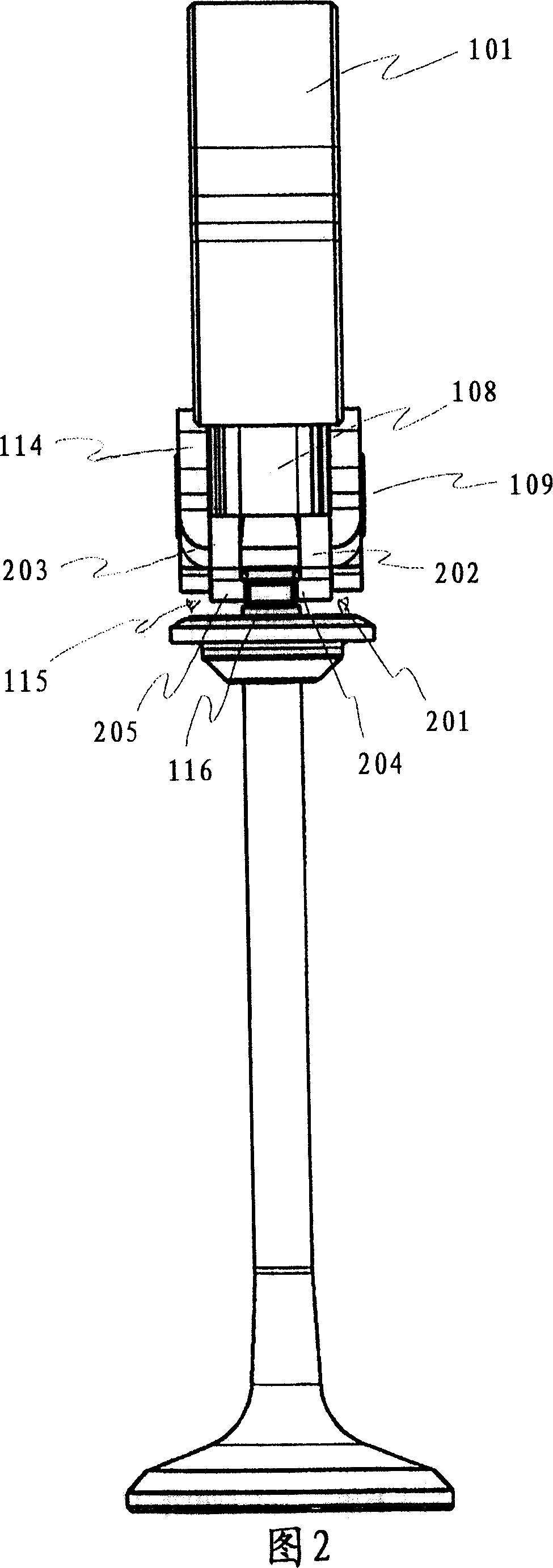

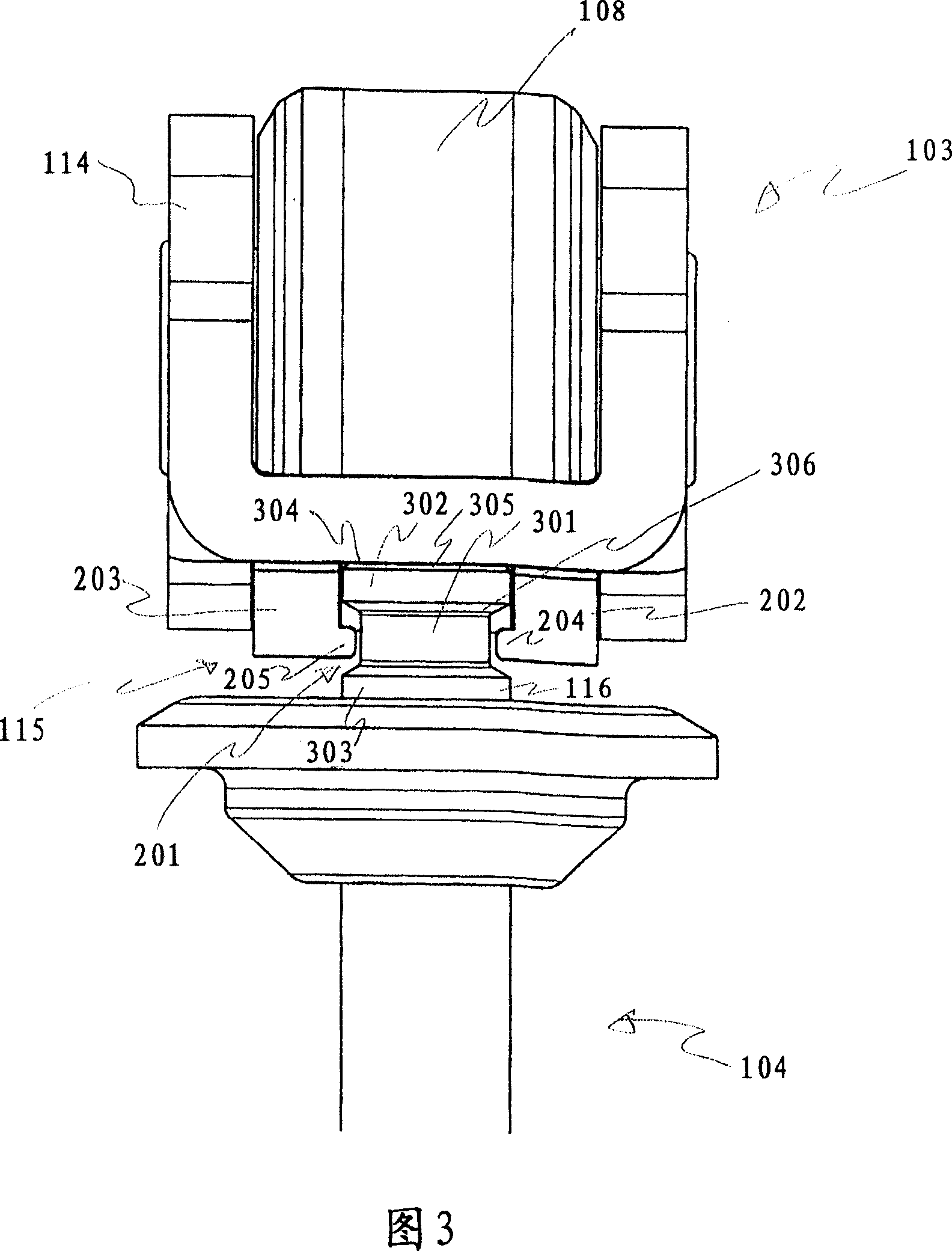

[0076]The figures shown in the drawings are schematic and not to scale. In the following description of FIGS. 1 to 3 , the same or corresponding parts use the same reference numerals.

[0077] FIG. 1 shows a side view of a valve train arrangement according to an exemplary embodiment of the invention. This valve train arrangement 100 has some parts including a cam 101 , a support 102 , a valve control lever 103 and a valve 104 . The cam 101 has an essentially circular shape with a projection in a subregion 105 . The contour in this portion of the protrusion 105 is at a greater distance from the cam axis of rotation 106 than the contour in the substantially circular region of the cam 101 is.

[0078] The cam with the axis of rotation 106 is fastened to a housing not shown in FIG. 1 . The circumference of the cam 107 rolls on a roller 108 or a roller 108 of the valve control lever 103 during rotation about the axis of rotation 106 . The roller 108 is mounted rotatably about a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com