Medium temperature alabastrine galze and its pren process

A snowflake glaze, medium temperature technology, which is applied in the field of glaze preparation and production of new glazes for daily-use ceramics and decorative art porcelain, can solve unsolved problems and achieve the effects of simple operation, stable glaze effect and moderate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

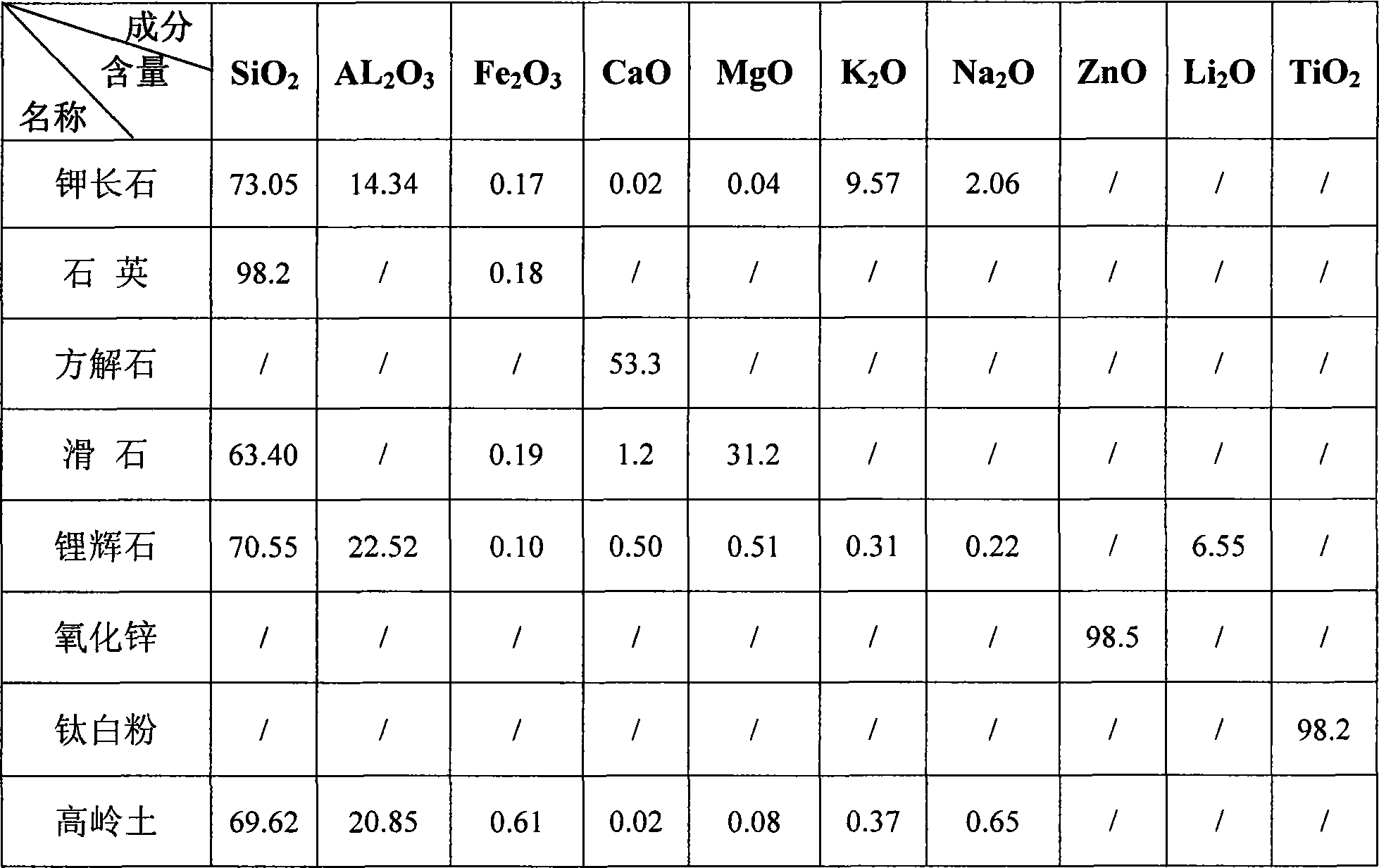

[0028] A snowflake glaze, including bottom glaze and top glaze, adopts titanium-zinc-boron combination technology, uses titanium, zinc crystals and boron compounds to freely adjust the viscosity of the glaze and the shape of the glaze flower in the bottom glaze and top glaze To suit various types of appliances. Its crystallization agent is introduced by TiO2 and ZnO, assists crystal growth aids such as MgO, CaO, Li2O, etc. to make crystal growth and development, makes borax into frit, and the introduction of boron adjusts crystal shape and glaze viscosity.

[0029] The formulation of the specific glaze is as follows:

[0030] Bottom glaze: feldspar 100 parts, quartz 55 parts, calcite 15 parts

[0031] Titanium dioxide 8 parts Burnt talc: 6 parts Spodumene 20 parts

[0032] Zinc oxide (calcined) 10 parts Kaolin 15 parts

[0033] Surface glaze: 100 parts of boron frit, 20 parts of calcite, 15 parts of quartz

[0034] Kaolin 5 parts

[0035] The production ...

Embodiment 2

[0037] The glaze principle and manufacturing process of embodiment two are the same as embodiment one, mainly because the ingredients are different from embodiment one, and the formula of concrete glaze is as follows:

[0038] Bottom glaze: feldspar 100 parts, quartz 55 parts, calcite 15 parts

[0039] 15 parts of titanium dioxide, 6 parts of burnt talc, 40 parts of spodumene

[0040] Zinc oxide (calcined) 30 parts Kaolin 15 parts

[0041] Surface glaze: boron frit 100 parts, calcite 20 parts, quartz 30 parts

[0042] Kaolin 20 parts

[0043] The ideal chemical composition of the glaze according to the composition of the above-mentioned embodiment one and embodiment two is:

[0044] Base glaze: SiO 2 36-45%AL 2 o 3 8-12% CaO 5-8%

[0045] TiO 2 4-6% ZnO 10-25% Li 2 O 1-1.5%

[0046] MgO 0.5-1.5% The rest are impurities.

[0047] Top glaze: B 2 o 3 8-15% SiO 2 20-38%K 2 O 5-15%

[0048] CaO 5-10% and the rest are impurit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com