Large multipoint hydraulically driven winch

A hoist and hydraulic technology, applied in hoisting devices, clockwork mechanisms, etc., can solve problems such as poor manufacturability, high production costs, and uneven distribution of stress points, and achieve improved manufacturing manufacturability, light weight, and complete machine The effect of safety factor and reliability increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

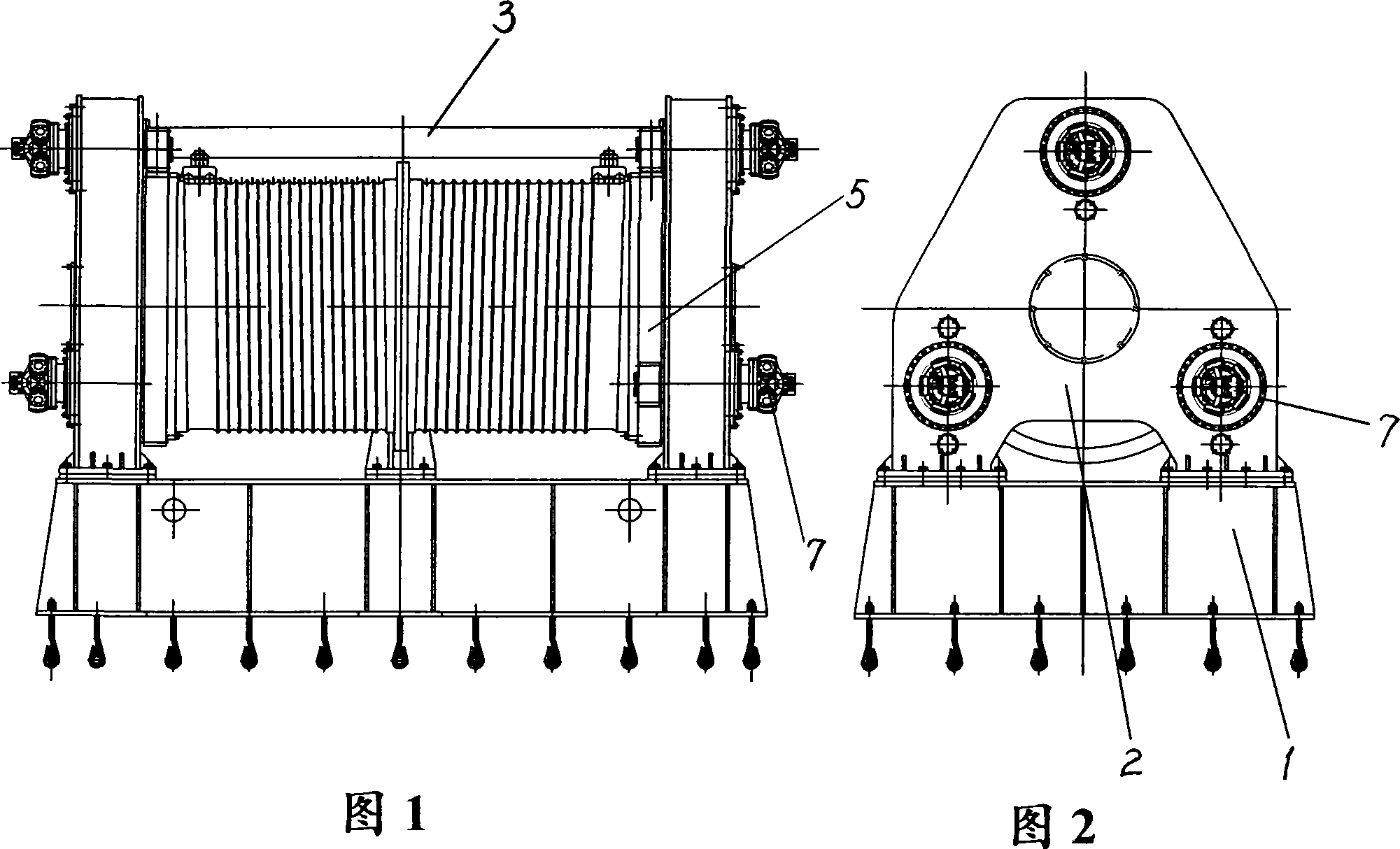

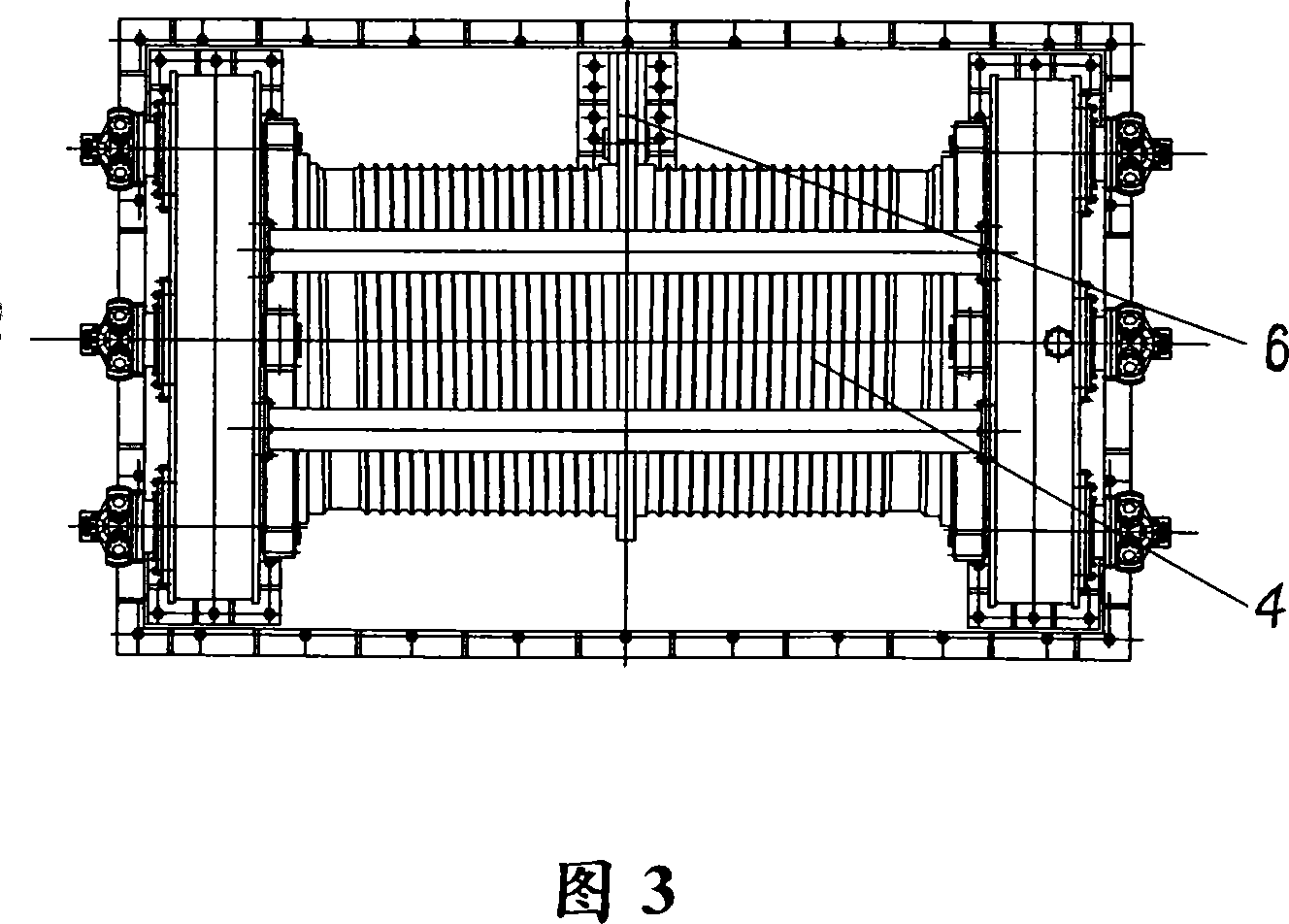

[0023] Referring to Fig. 1 to Fig. 3, the present invention is a large-scale multi-point hydraulically driven hoist, especially a large-scale six-point hydraulically driven hoist, which is equipped with a base 1, a side bracket 2, a beam 3, a double drum 4, and a large gear at the end 5. Steel wire rope and hydraulic turning device7. The side supports 2 are arranged on two sides, and the two side supports 2 are connected by two upper beams 3 to form an integral frame structure.

[0024] Hydraulic rotary device 7 is made up of low-speed high-torque hydraulic motor, brake, planetary reducer and pinion. Six hydraulic swivel devices 7 are arranged on two side supports 2 respectively, and three hydraulic swivel devices 7 are arranged on each side support 2 . The pinion gears of the hydraulic slewing device 7 are arranged in equilateral triangle positions, and are meshed with the terminal bull gears 5 located on both sides of the duplex reel 4 to form an open gear transmission syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com