Process for manufacturing secondary batteries

A manufacturing method and secondary battery technology, applied in secondary battery manufacturing, secondary battery, electrode manufacturing, etc., can solve problems such as zero discharge efficiency and poor discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

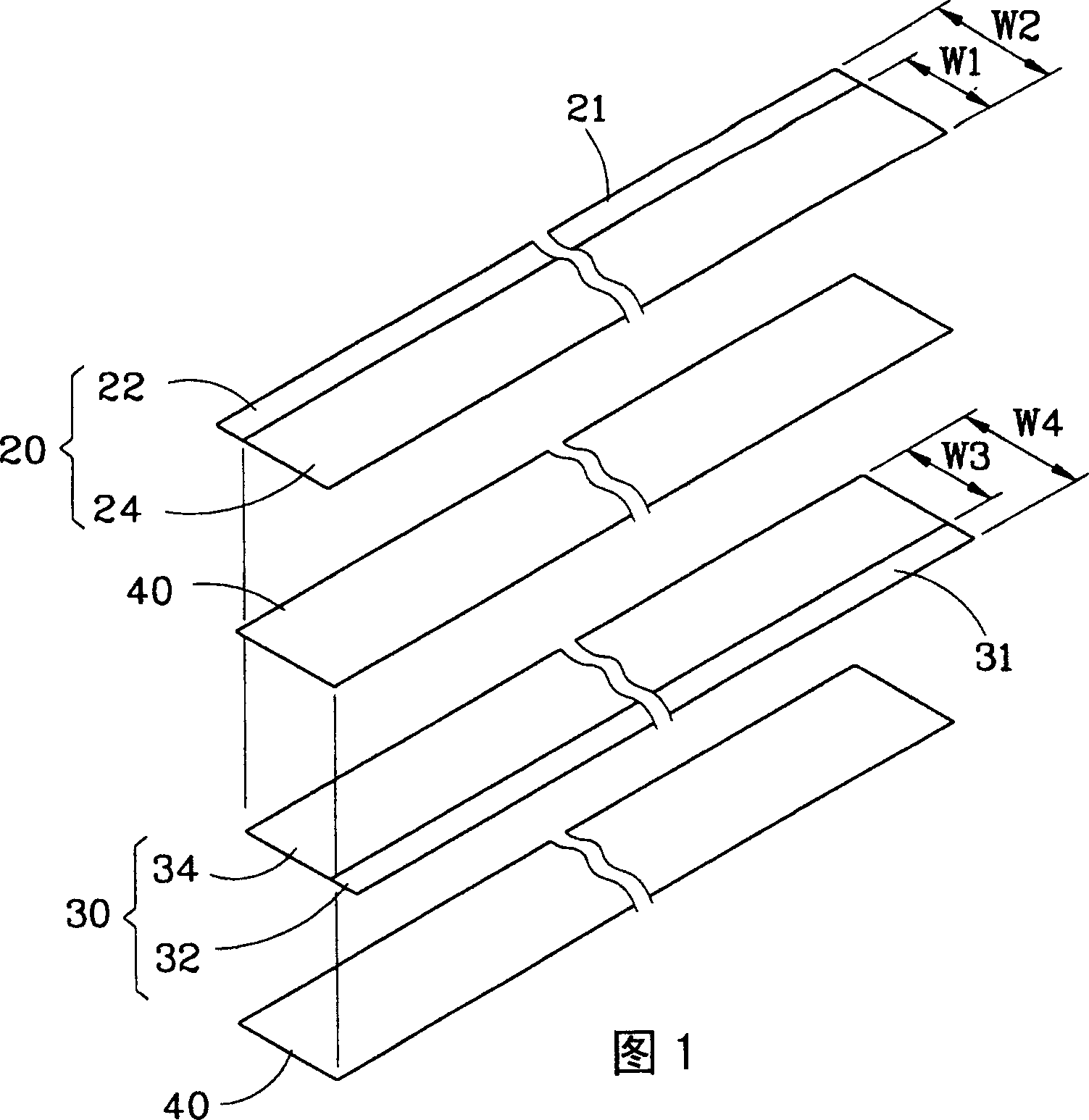

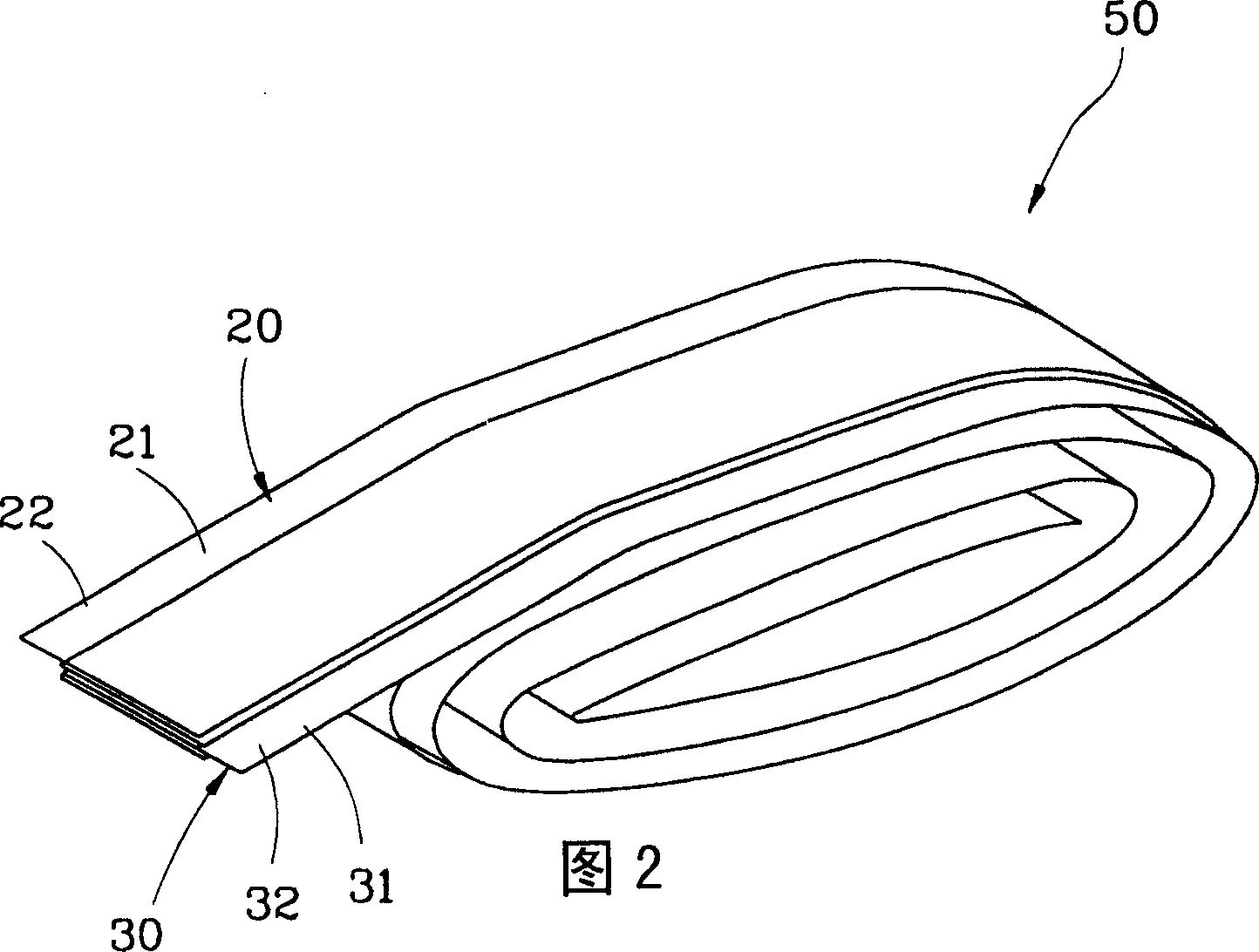

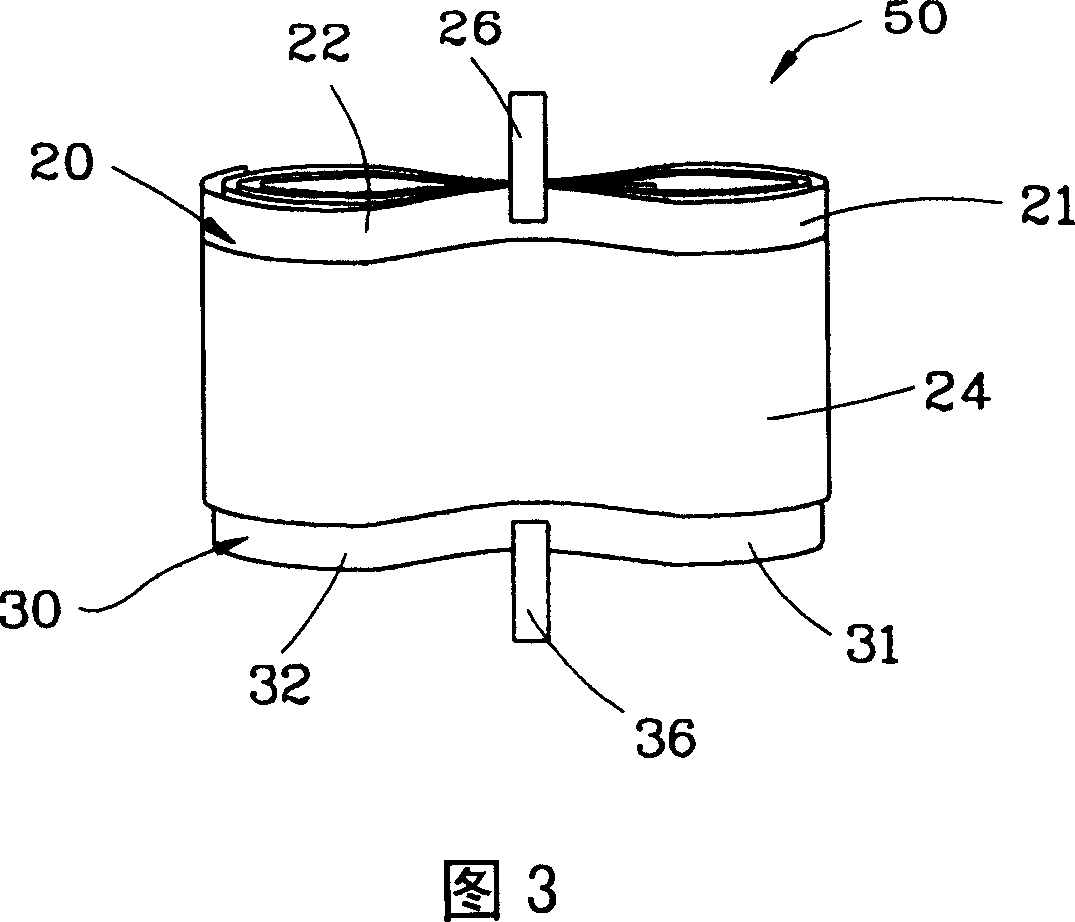

[0026] The first preferred embodiment of the present invention provides a method for manufacturing a secondary battery 10. First, as shown in FIG. A long and narrow aluminum sheet 22 and a positive electrode material film 24 cover the two surfaces of the aluminum sheet 22, the positive electrode material film 24 is a LiCoO2 film, and the width w1 of the positive electrode material film 24 is smaller than the width w2 of the aluminum sheet 22, so that The positive electrode forms a bare aluminum region 21; the negative electrode 30 has a long and narrow copper sheet 32 and a negative electrode material film 34 covering the two surfaces of the copper sheet 32, the negative electrode material film 34 is a mesophase crystalline carbon (MCMB) film, The width w3 of the negative electrode material film 34 is approximately equal to the width w1 of the positive electrode material film 24 and smaller than the width w4 of the copper sheet 32, so that the negative electrode 30 has a bare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com