Track structure of magnetic floating traffic and manufacturing method therefor

A manufacturing method and track technology, which can be applied to tracks, roads, buildings, etc., can solve the problems of increased engineering costs, increased welding and orthopedic workload, increased track beam load, etc., to achieve the best shock absorption performance, torsion resistance and resistance The effect of improving longitudinal deformation ability and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

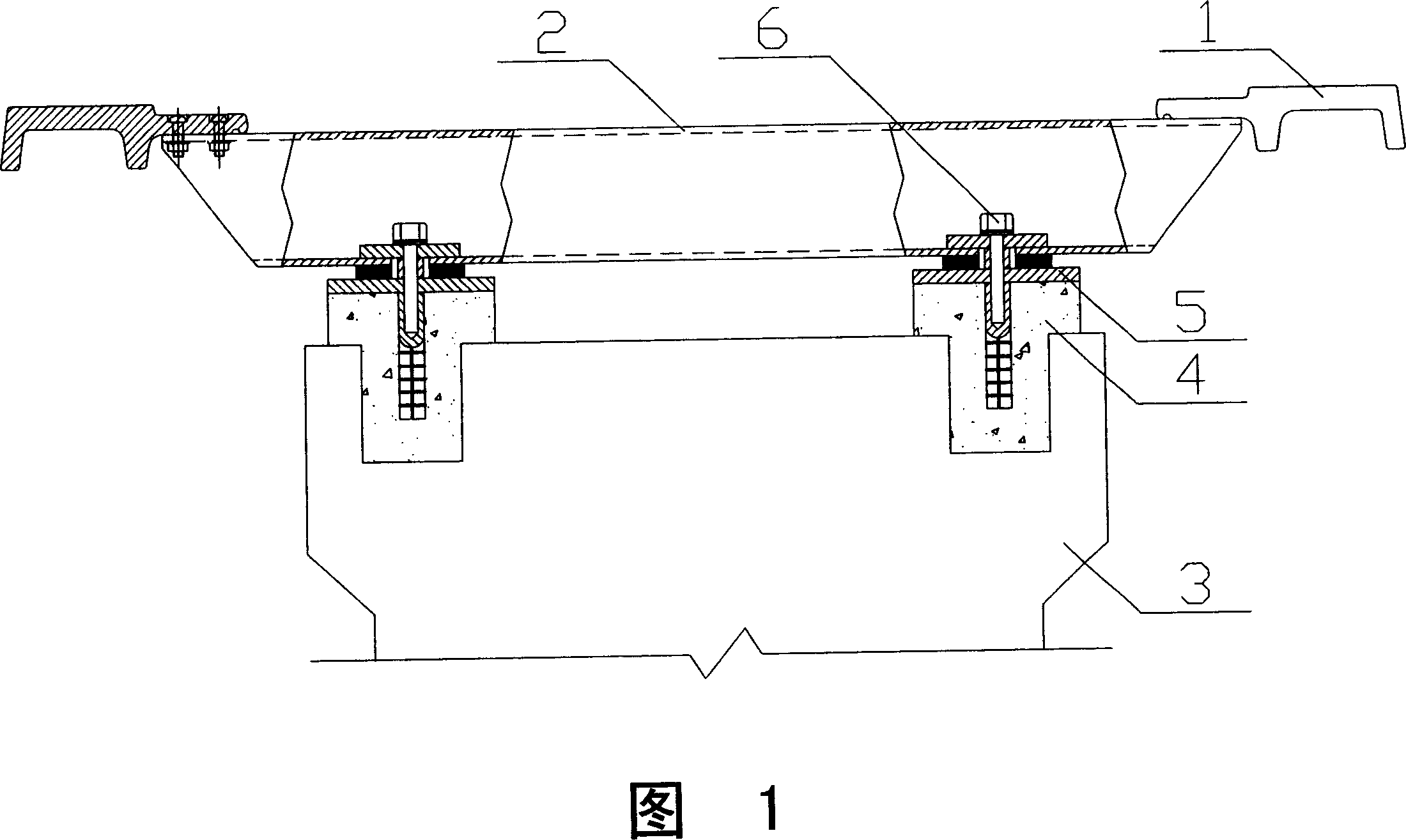

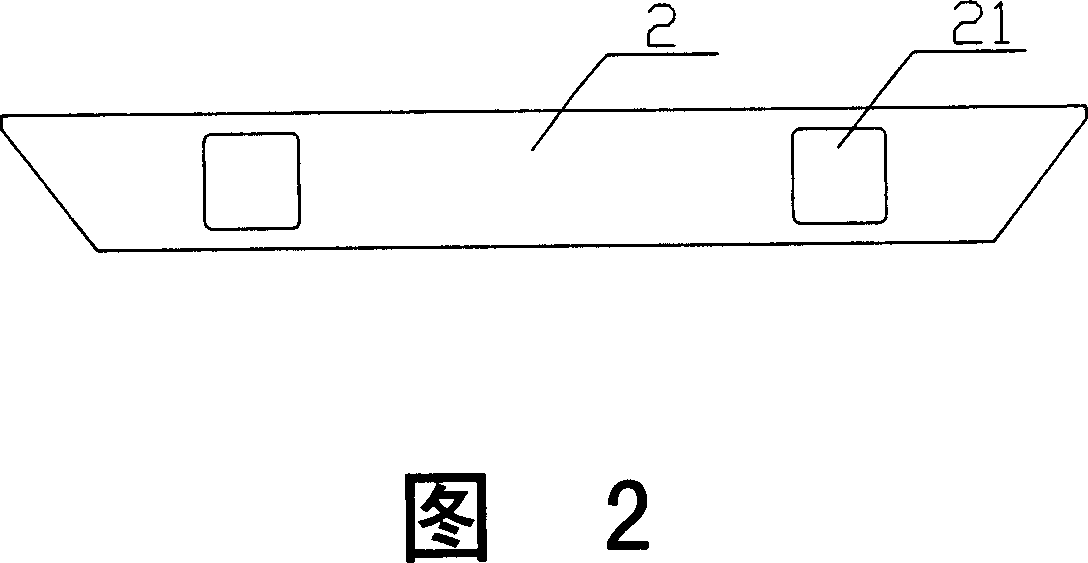

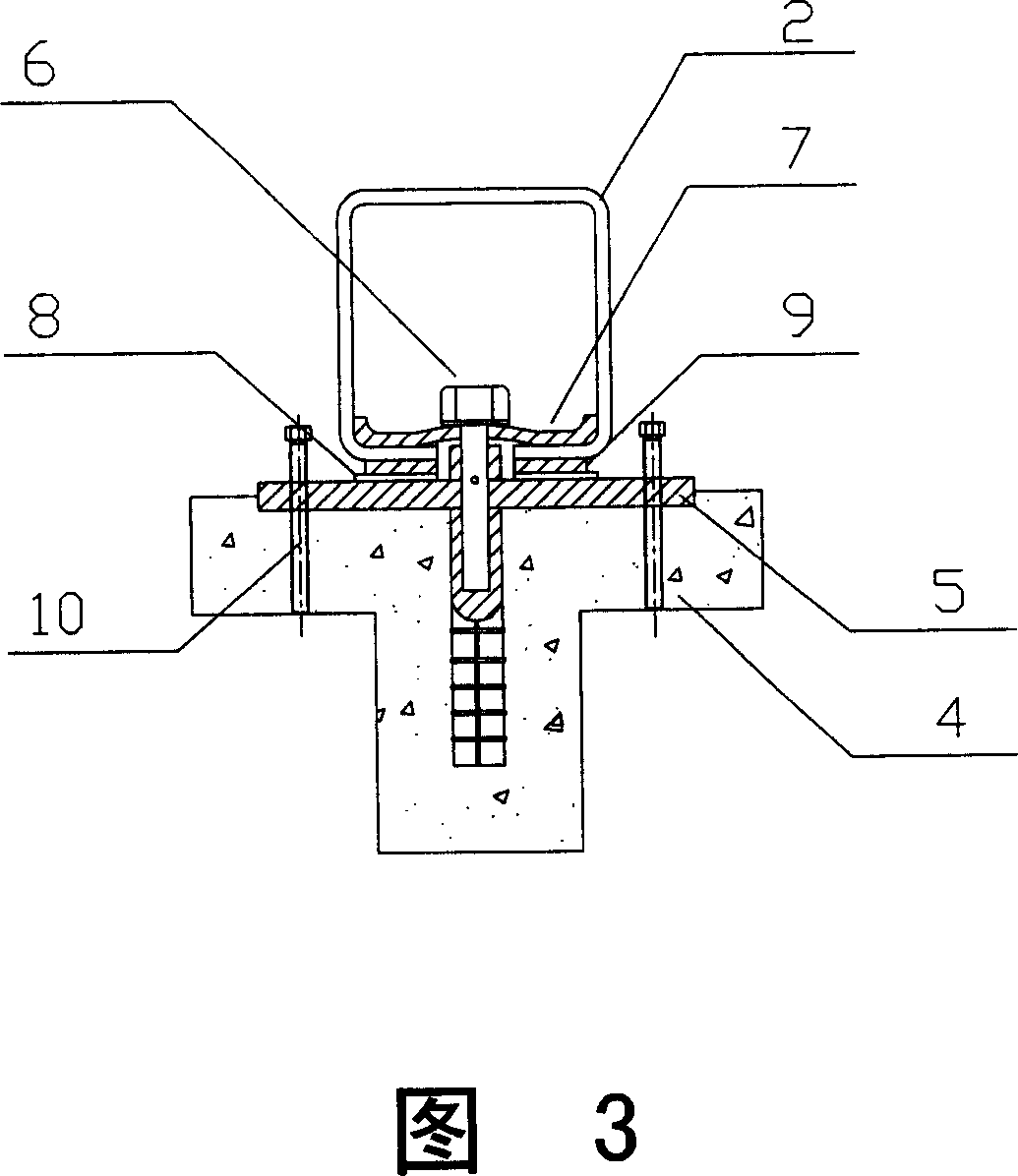

[0023] Please refer to Fig. 1~Fig. 9, all the same components in the figure are represented by the same symbols. As can be seen from the figures, the track structure of the present invention mainly includes: track beam 3, the sleeper 2 supported and fixed on the track beam 3 by a connecting structure, and the guide rails (F steel plates) supported and fixed on both sides of the upper surface of the sleeper 2 )1.

[0024] As shown in Figure 3, the connection structure mainly includes a spacer 4 with a T-shaped cross-section and fasteners such as bolts 6. Height-adjusting washers 8, leveling bolts 10 and elastic Backing plate 9. In addition, for the convenience of connection, an embedded steel plate 5 can be arranged on the spacer 4 .

[0025] The cushion block 4 is arranged between the guide rail 1 and the track beam 3 . Pad 4 is made of concrete material, can be prefabricated in factory, also can support formwork to make on the spot. On the one hand, the block 4 plays the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com