Method of preparing aluminum oxide from clay mine by citric acid extraction

A technology of aluminum citrate and citric acid, applied in chemical instruments and methods, alumina/hydroxide preparation, inorganic chemistry, etc., can solve the problems of large environmental pollution, low income, long cycle, etc., and achieve weakened equipment corrosion resistance. performance, increase the rate of hydrolysis, reduce the effect of acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

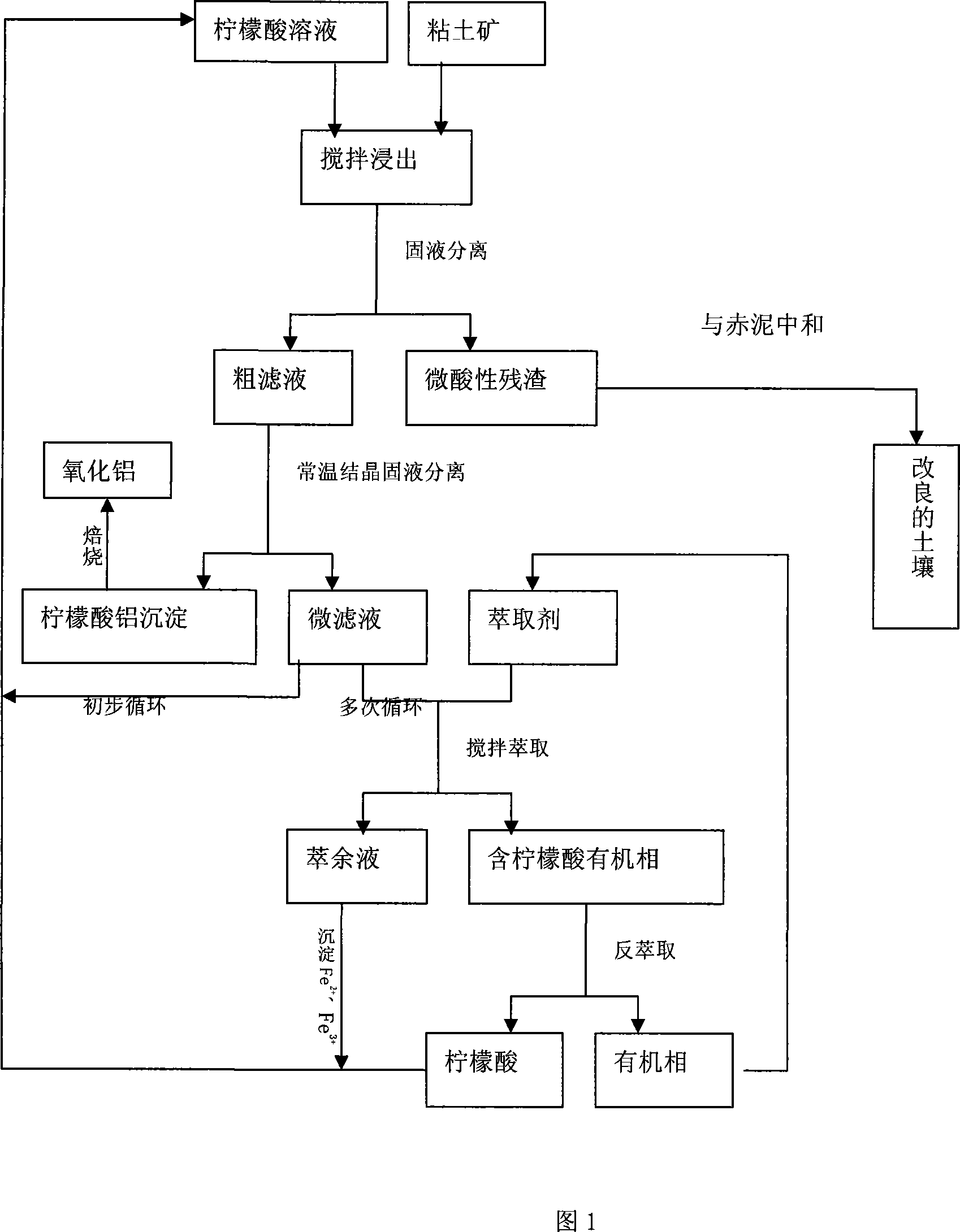

Method used

Image

Examples

Embodiment 1

[0026] Will 1 # After crushing and ball milling the ore samples, the clay ore is made into particles with a particle size of 833 μm to 74 μm, placed in a muffle furnace and roasted at 625°C for 3 hours, leached with a citric acid solution with a mass concentration of 6%, and the stirring intensity is 300r / min, the mass concentration of pulp dry ore is 10%, the treatment time is 6 hours, four stages of continuous leaching, the leaching slag of the previous stage is used as the leaching ore sample of the latter stage. After each stage of leaching is completed, filter while hot. The slag after four stages of leaching was taken to analyze the content of Al2O3, SiO2 and Fe2O3. The crude filtrate was placed for 12 hours, a large amount of white precipitate was formed, and microfiltration was performed. The microfiltrate is returned to the leaching section for recycling.

[0027] chemical composition

Embodiment 2

[0029] Will 2 # After crushing and ball milling the ore samples, the clay ore is made into particles with a particle size of 833 μm to 74 μm, placed in a muffle furnace and roasted at 575°C for 2.5 hours, leached with a citric acid solution with a mass concentration of 4%, and the stirring intensity is 200r / min, the pulp concentration is 15%, and the treatment time is 4 hours. There are three stages of continuous leaching, and the leaching slag of the previous stage is used as the leaching ore sample of the latter stage. After each stage of leaching is completed, filter while hot. The slag after two stages of leaching was taken to analyze the content of Al2O3, SiO2 and Fe2O3. The crude filtrate was placed at room temperature for 12 hours, a large amount of white precipitate was formed, and microfiltration was performed. The microfiltrate is returned to the leaching section for recycling.

[0030] chemical composition

Embodiment 3

[0032] Will 3 #After crushing and ball milling the ore samples, the clay ore is made into particles with a particle size of 833 μm to 74 μm, placed in a muffle furnace and roasted at 675°C for 3.5 hours, and leached with a citric acid solution with a mass concentration of 4%, with a stirring intensity of 300r / min, the pulp concentration is 10%, and the treatment time is 5 hours. There are three stages of continuous leaching, and the leaching slag of the previous stage is used as the leaching ore sample of the latter stage. After each stage of leaching is completed, filter while hot. The slag after three stages of leaching was taken to analyze the content of Al2O3, SiO2 and Fe2O3. The crude filtrate was placed at room temperature for 12 hours, a large amount of white precipitate was formed, and microfiltration was performed. The microfiltrate is returned to the leaching section for recycling.

[0033] chemical composition

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com