Piezoelectric oscillator active valve type piezoelectric pump

A piezoelectric vibrator and active valve technology, used in pumps, machines/engines, liquid variable capacity machines, etc., can solve problems such as pump valve hysteresis, improve output performance, solve sealing difficulties, and simplify control methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

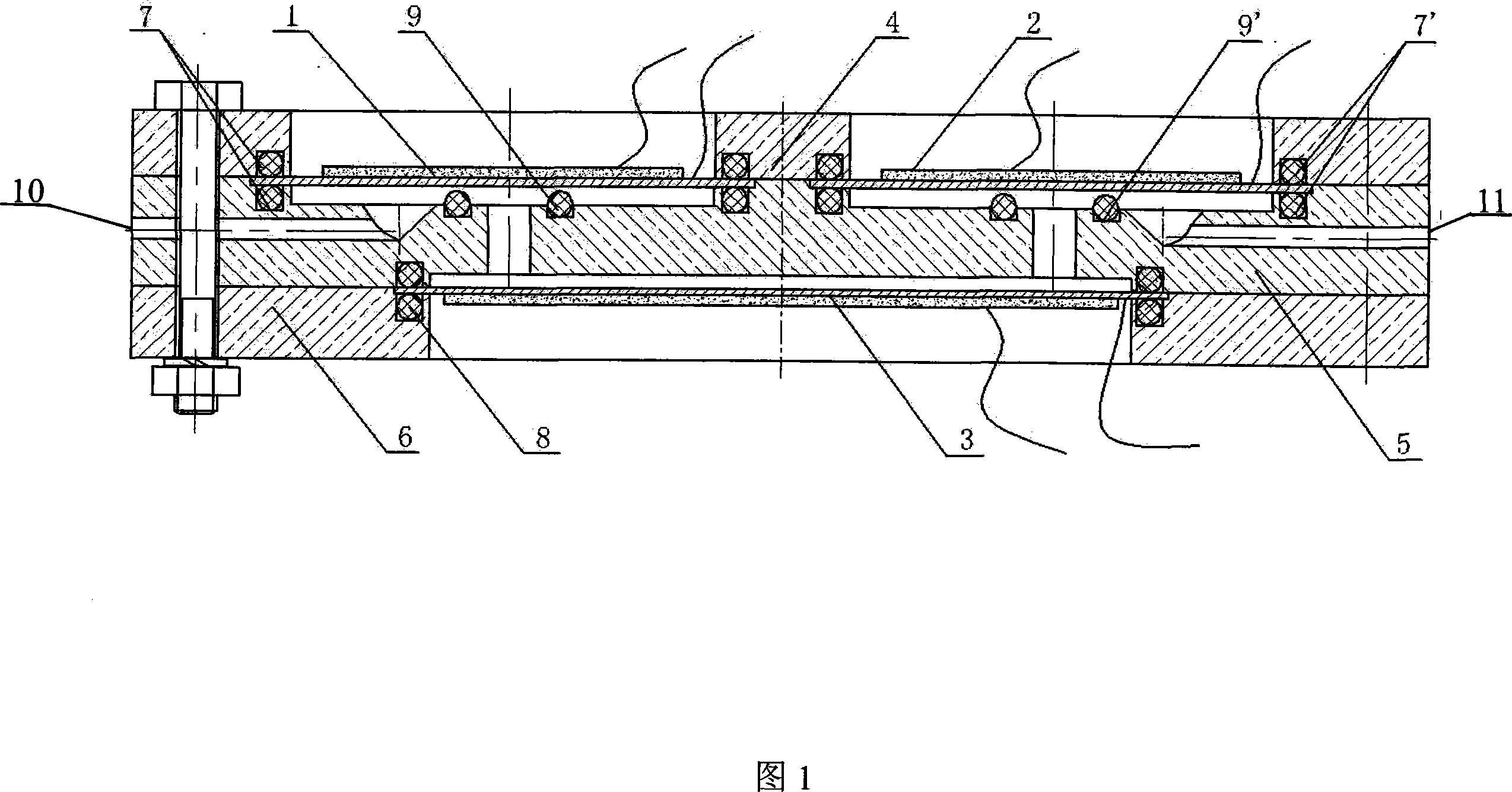

[0018] The pump body has a water inlet 10 and a water outlet 11 respectively connected to the pump chamber, the upper gland 4, the pump body 5 and the lower gland 6 are fixedly connected, and the edge of the inlet valve driving vibrator 1 is connected to the pump body through a flexible sealing ring 7 , the edge of the outlet valve driving vibrator 2 is connected to the pump body through a flexible sealing ring 7 ′, the valve port flexible ring 9 is fixed around the valve port, and the edge of the pump chamber driving vibrator 3 is fixedly connected to the pump body through a flexible material sealing ring 8 .

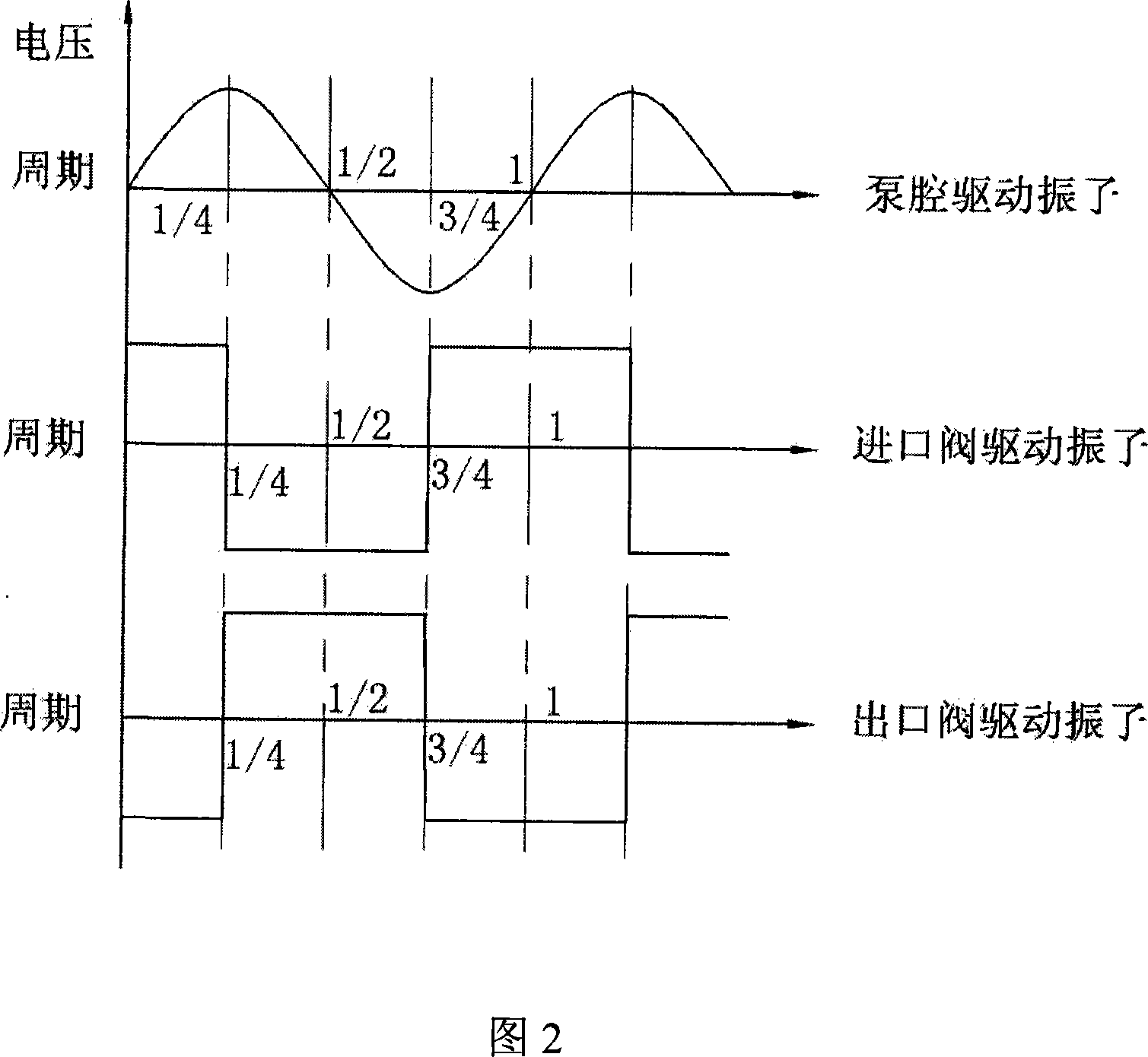

[0019] Referring to Fig. 1, the upper gland 4, the pump body 5 and the lower gland 6 are made of plexiglass as the body of the piezoelectric pump; the inlet and outlet valves 1 and 2 are respectively composed of piezoelectric vibrators, the upper gland 4 and the pump The body 5 constitutes the inlet and outlet valves. In order to make the driving piezoelectric vibrator ...

Embodiment 2

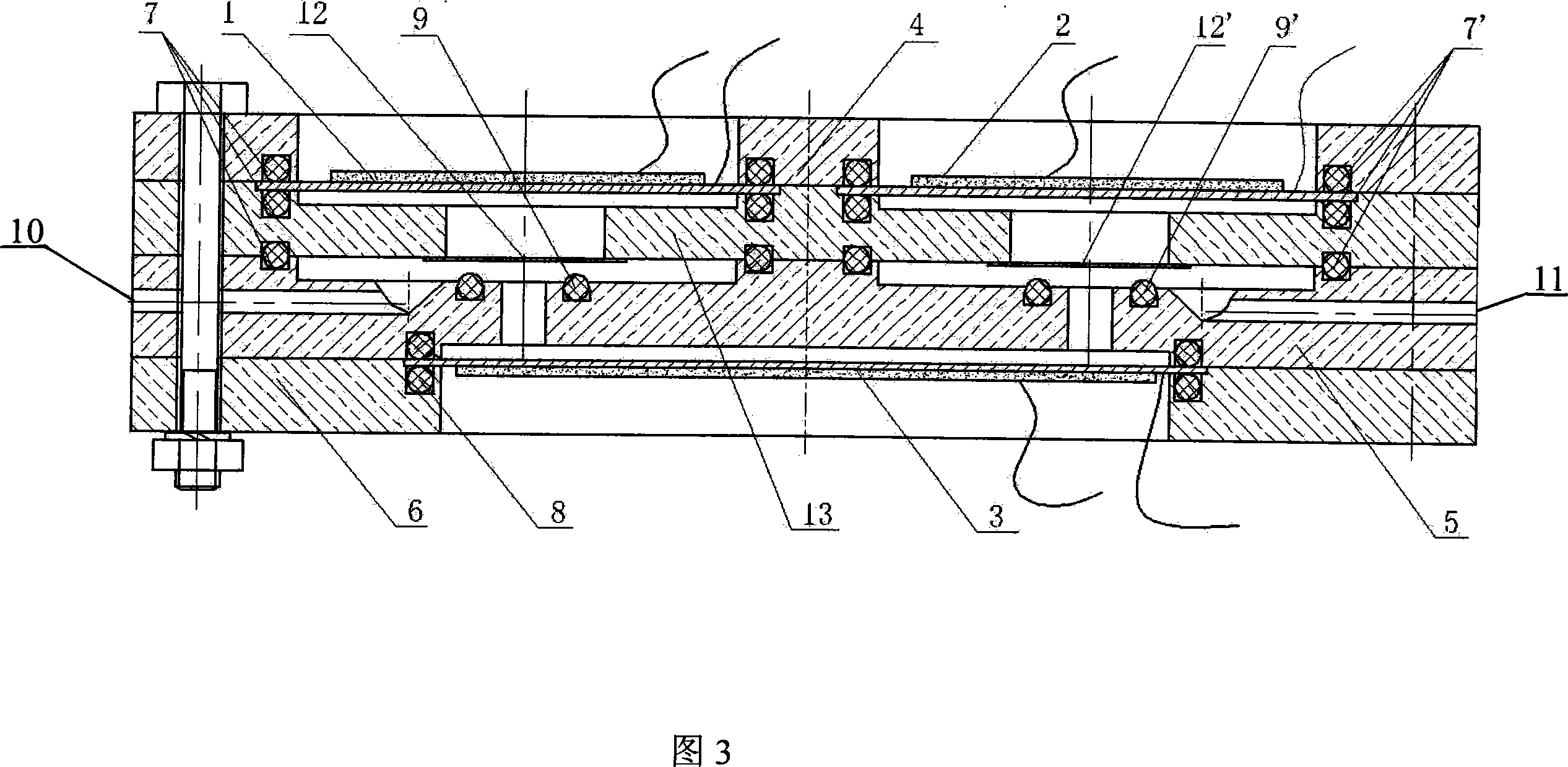

[0027] The pump body has a water inlet 10 and a water outlet 11 respectively connected to the pump chamber, the upper gland 4, the pump body 5 and the lower gland 6 are fixedly connected, and the edge of the inlet valve driving vibrator 1 is connected to the pump body through a flexible sealing ring 7 , the edge of the outlet valve drive vibrator 2 is connected to the pump body through a flexible material sealing ring 7', the valve port flexible ring 9 is fixed around the valve port inside the pump body, and the edge of the pump cavity driving vibrator 3 is connected to the pump body through a flexible material sealing ring 8' The body is fixedly connected, and a valve body 13 and a valve membrane 12 are added between the upper gland 4 and the pump body 5, and the two are fixedly connected with the valve body respectively.

[0028] Referring to FIG. 3 , compared with Example 1, the body of the piezoelectric pump has a valve membrane 12 and a valve body 13 added. The inlet and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com