Methods for reducing particulate matter emissions from diesel engine exhaust using ethanol/diesel fuel blends in combination with diesel oxidation catalysts

A diesel engine, particulate matter technology, applied in the direction of adding non-fuel substances to fuel, combustion engine, machine/engine, etc., can solve the problems of high emissions, diesel engine efficiency and effectiveness damage, increase of particulate matter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Preparation of Ethanol / Diesel Blends

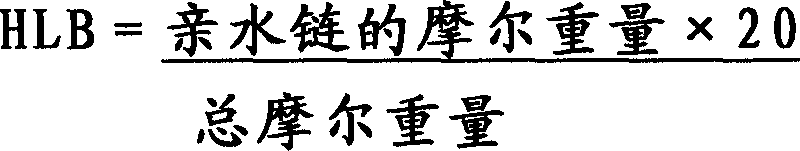

[0059] Exemplary ethanol / diesel blends of the present invention were prepared by mixing fuel additives and ethanol / diesel blends. Specifically, a fuel additive composition was prepared by blending the components, oleic acid diethanolamide and ethoxylated oleic acid, in a 1:1 ratio. Subsequently, 1% of this fuel additive composition was added to a 7.7% ethanol / 92.3% diesel blend to obtain a stable, optically clear, stable microemulsion fuel blend in which the 92.3% diesel blend The product contains, for example, qualified diesel oil US No. 1 diesel oil, that is, 10% aromatic diesel oil containing 0.1% cetane improver.

Embodiment 2-D

[0060] Example 2 - Combination of DOC and Ethanol / Diesel Blends

[0061]The unexpected improvement of the method of the present invention in reducing PM in diesel engine exhaust can be demonstrated as follows. The US EPA Engine Dynamometer Schedule for Heavy-Duty Diesel Engines described in Appendix I of CFR Title 40 Part 86 can be used as the basic test sequence. Controlled emissions were determined during a cold cycle followed by four hot start transient test cycles, each separated by the required 20 minute soak time. During the three hot-start phases of the test, emission characteristic measurements for the 13-cycle test were obtained.

[0062] Exemplary ethanol / diesel blends include Canadian No. 1 and No. 2 diesel base fuels, and blends of each with 7.0% ethanol and 1% stabilizing additive. Diesel oxidation catalysts, including type AZ29, are certified under the US EPA Voluntary DieselRetrofit program. The catalyst has platinum loaded on a molecular sieve containing a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com