Filter element recovery method and device for elevator collaborative production line

A recovery method and production line technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve problems such as long continuous working hours of welding equipment, large output of elevator cooperative production lines, high production costs of enterprises, etc., and achieve reuse , improve the recovery effect, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

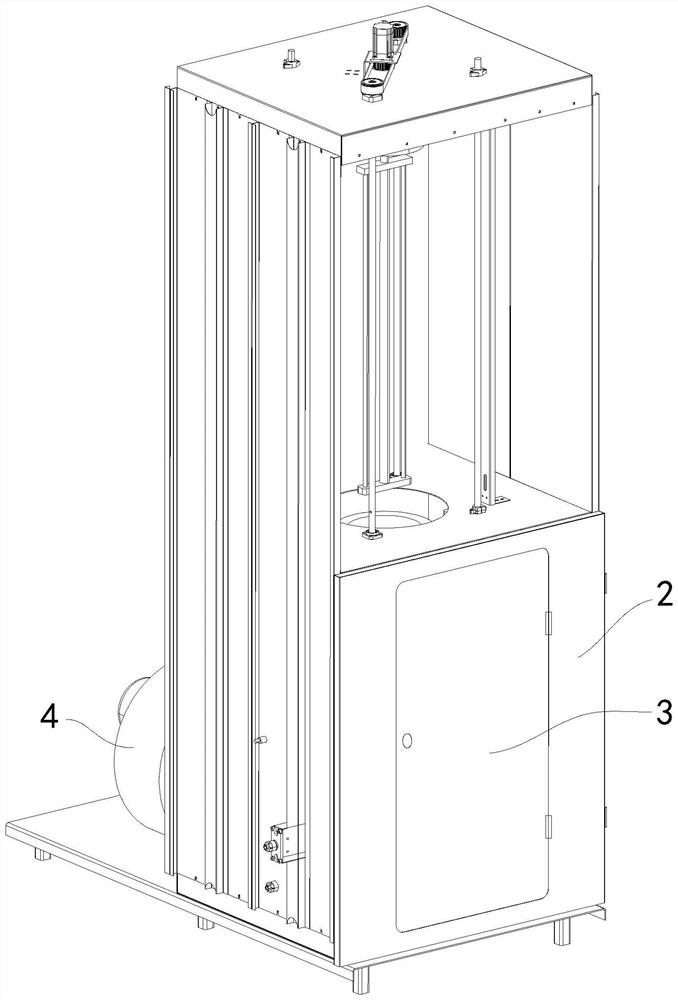

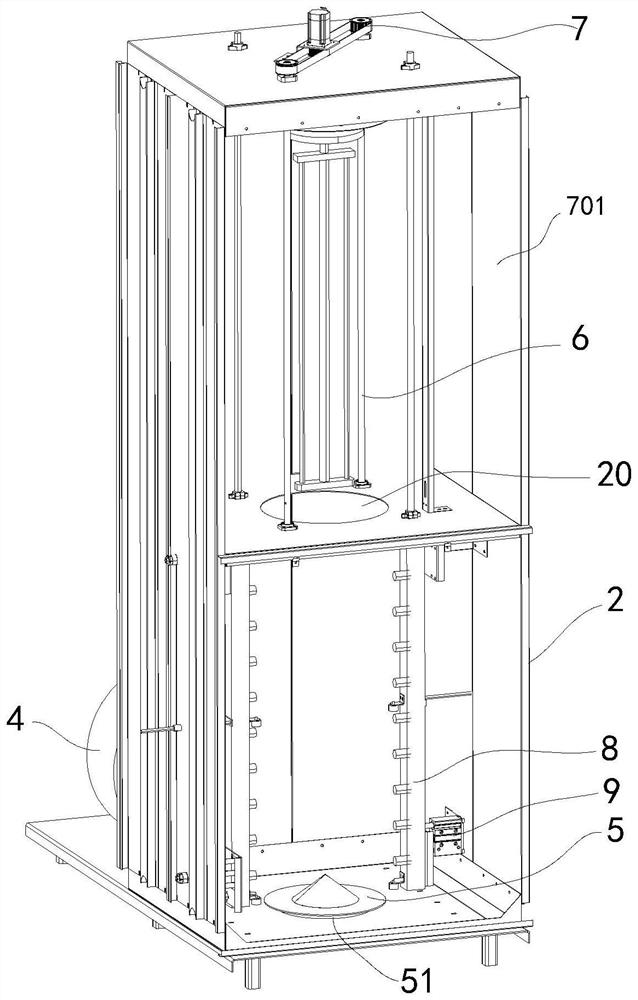

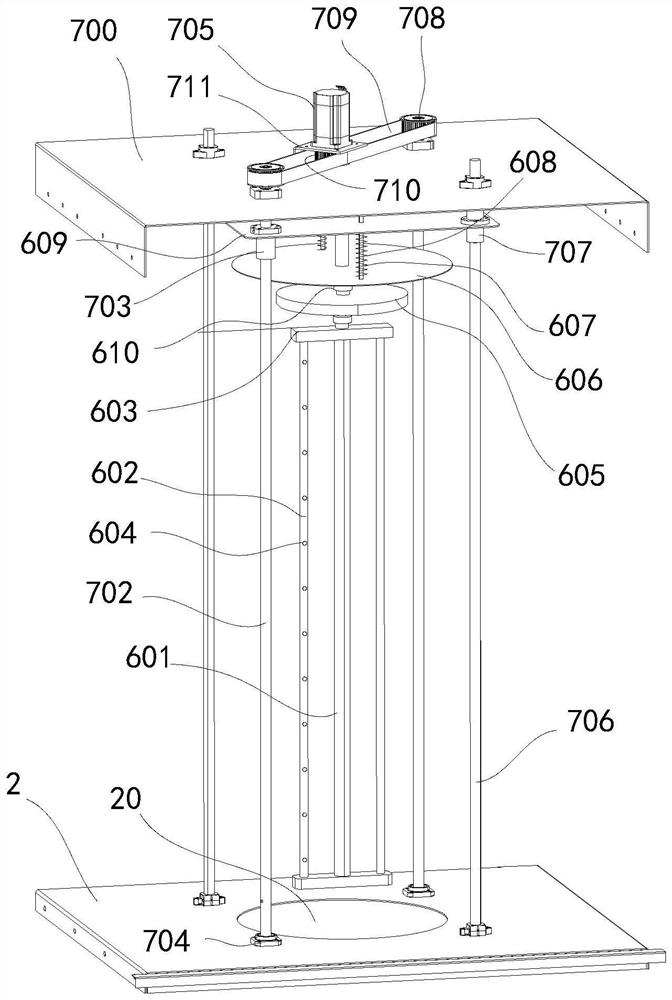

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0028] Example. The method for recovering the filter element of the elevator cooperative production line includes the following steps: a. Close one end of the filter element 1, and pass high-pressure airflow into the interior of the filter element 1 from the other end of the filter element 1, and the high-pressure airflow flows out from the outer peripheral surface of the filter element 1, and takes away the filter element 1 Part of the particle impurities on the outer peripheral surface; b. From the outside of the filter element 1, a plurality of vertically arranged air nozzles 801 are used to spray high-pressure airflow to take away another part of impurities on the outer peripheral surface of the filter element 1. While spraying high-pressure airflow, the filter element 1 Make a rotating movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com