Refrigerant distributor of compression refrigeration falling-film evaporator

A technology for falling film evaporators and refrigerant distributors, which is applied to evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of high processing difficulty and high cost of distributors, reduce flashing phenomenon, reduce The effect of charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

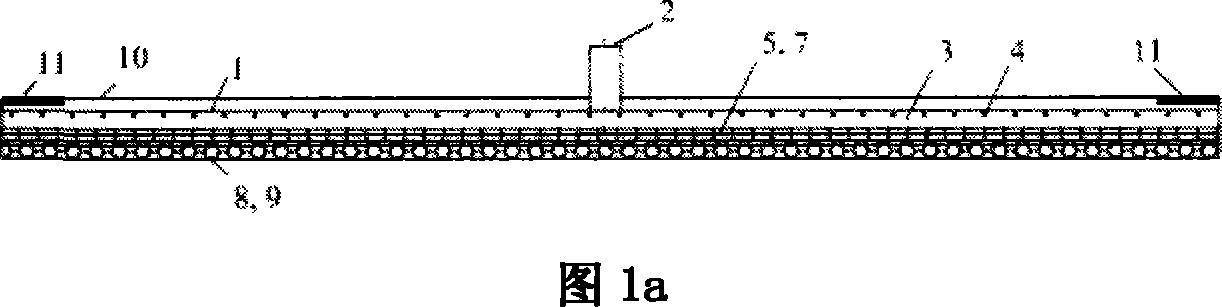

[0024] As shown in Fig. 1a and Fig. 1b, a schematic diagram of a preferred embodiment of the present invention is shown in the figure, and the dispenser is generally indicated by numeral 1. The distributor includes: refrigerant inlet 2, refrigerant longitudinally stretched distribution pipe 3 and refrigerant transversely stretched capillary tube 4, porous material layer (using wire mesh) 5, drawn steel mesh 7, porous plate 8, flow guide silk screen9. In addition to the above components, there are also an upper sealing plate 10 and a demister 11 .

[0025] In the vap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com