Microballons of laminar dual hydroxy composite metal oxide and preparation method

A layered double hydroxyl and composite metal technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as catalyst separation and recycling impact, Achieve the effect of being suitable for industrialized production and the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

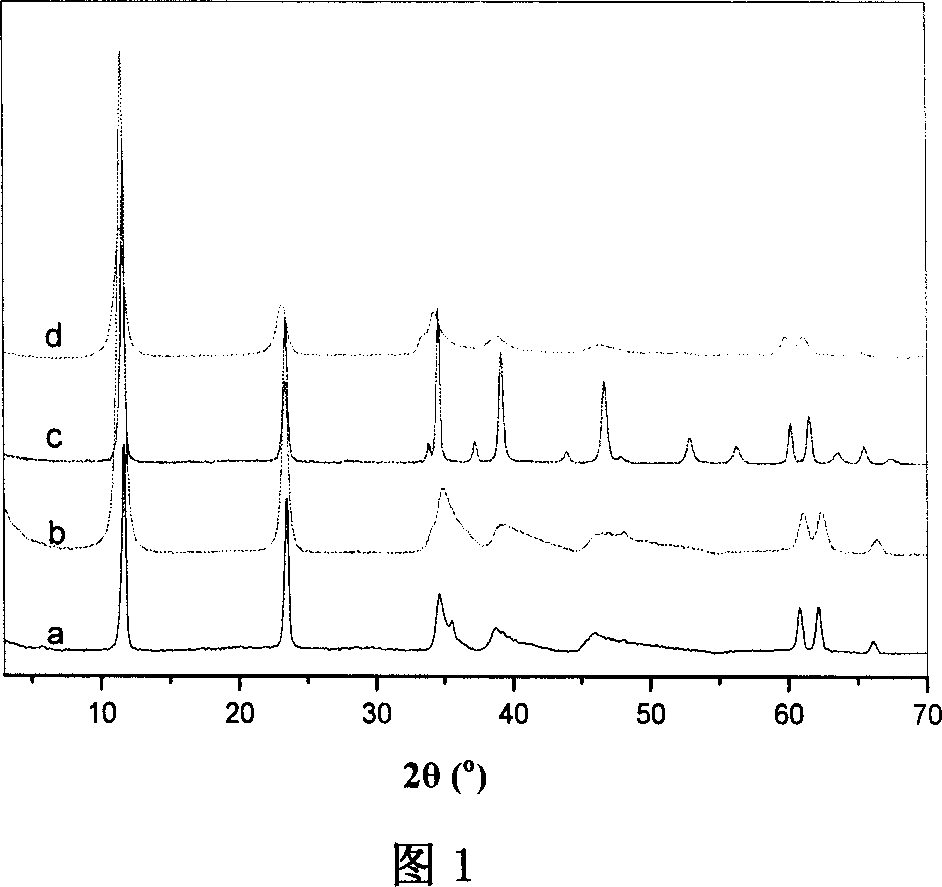

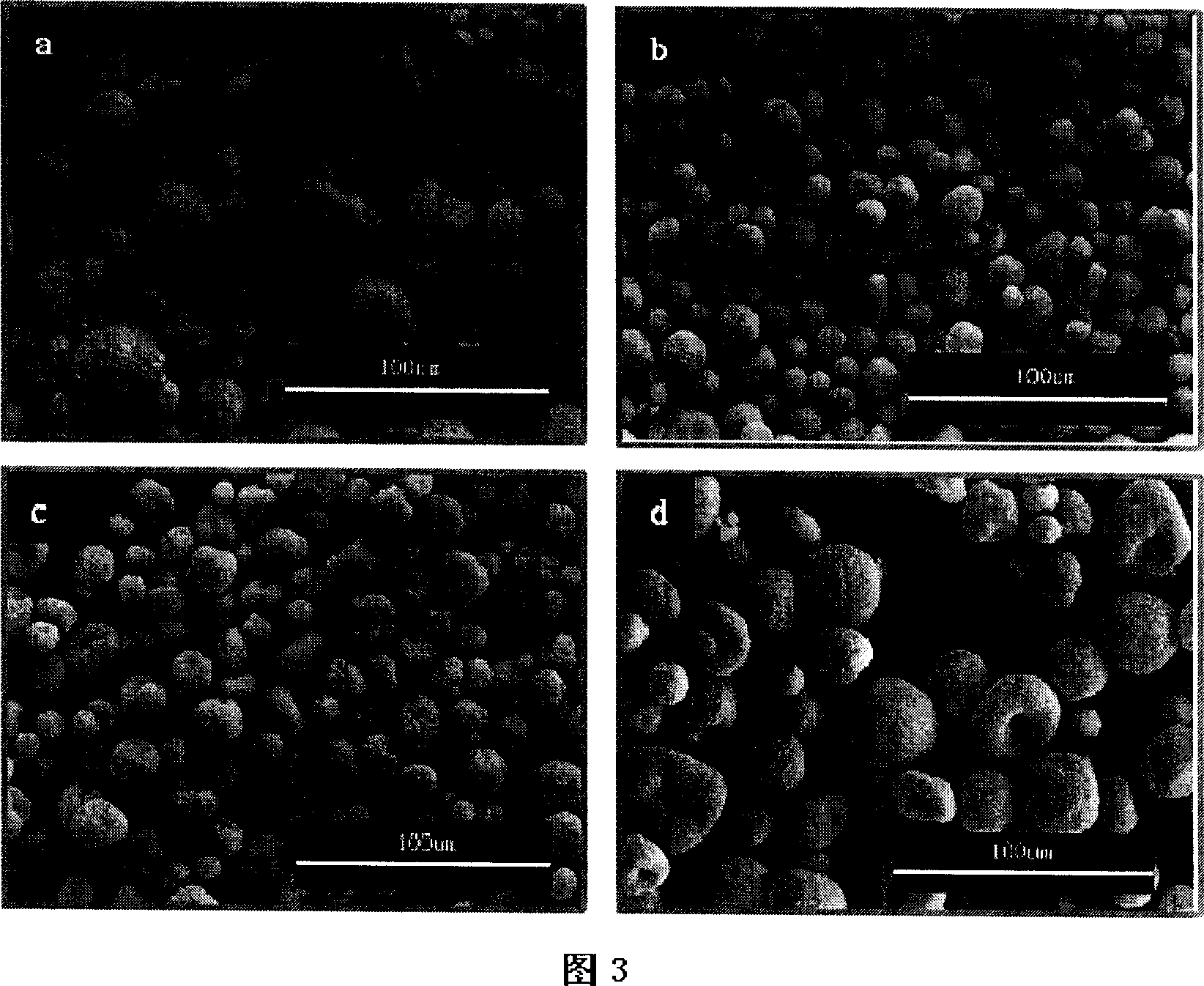

Embodiment 1

[0042] A: Weigh 61.54g Mg(NO 3 ) 2 ·6H 2 O and 45.02g Al(NO 3 ) 3 9H 2 O was dissolved in deionized water to make 300mL mixed salt solution; then weighed 23.04g NaOH and 25.44g NaOH 2 CO 3 Dissolve in deionized water to make 300mL mixed alkali solution; add the above two mixed solutions into the total back-mixed liquid membrane reactor at the same time, adjust the slit width between the reactor rotor and stator to 0.02mm, the working voltage to 100V, and the rotor speed The temperature is 4000rpm, and the obtained mixed slurry is added to the crystallization kettle for stirring, and the temperature of the mixed slurry in the kettle is kept at 95-105°C for reflux crystallization for 6 hours to obtain magnesium-aluminum hydrotalcite;

[0043] B: fully wash the product prepared in step A with deionized water so that the pH of the supernatant is 7-8, add deionized water and fully stir to form a slurry with a solid content of 2%;

[0044] C: Add PVA accounting for 1% of the ...

Embodiment 2

[0047] A: with embodiment 1;

[0048] B: with embodiment 1;

[0049] C: Add PVA accounting for 5% of the total weight of the slurry to the hydrotalcite-like slurry in step B, and fully stir to make the system in a uniform colloidal state;

[0050] D: Pour the colloidal slurry in step C into the atomizing wheel rotating at a high speed of 12,000 rpm with a constant flow pump at a flow rate of 6 to 10 mL / min, and set the temperature at the inlet of the spray drying to 150°C. Perform spray granulation.

Embodiment 3

[0052] A: with embodiment 1;

[0053] B: with embodiment 1;

[0054] C: Add PVA accounting for 10% of the total weight of the slurry to the hydrotalcite-like slurry in step B, and fully stir to make the system in a uniform colloidal state;

[0055] D: Pour the colloidal slurry in step C into the atomizing wheel rotating at a high speed of 12,000 rpm with a constant flow pump at a flow rate of 6 to 10 mL / min, and set the temperature at the inlet of the spray drying to 150°C. Perform spray granulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com