Method and apparatus for removing organic substance from oily water from oilfield

A technology for organics and oil fields, applied in separation methods, chemical instruments and methods, petroleum industry, etc., and can solve the problems of reducing organic compounds, unclear, and undisclosed processing technologies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

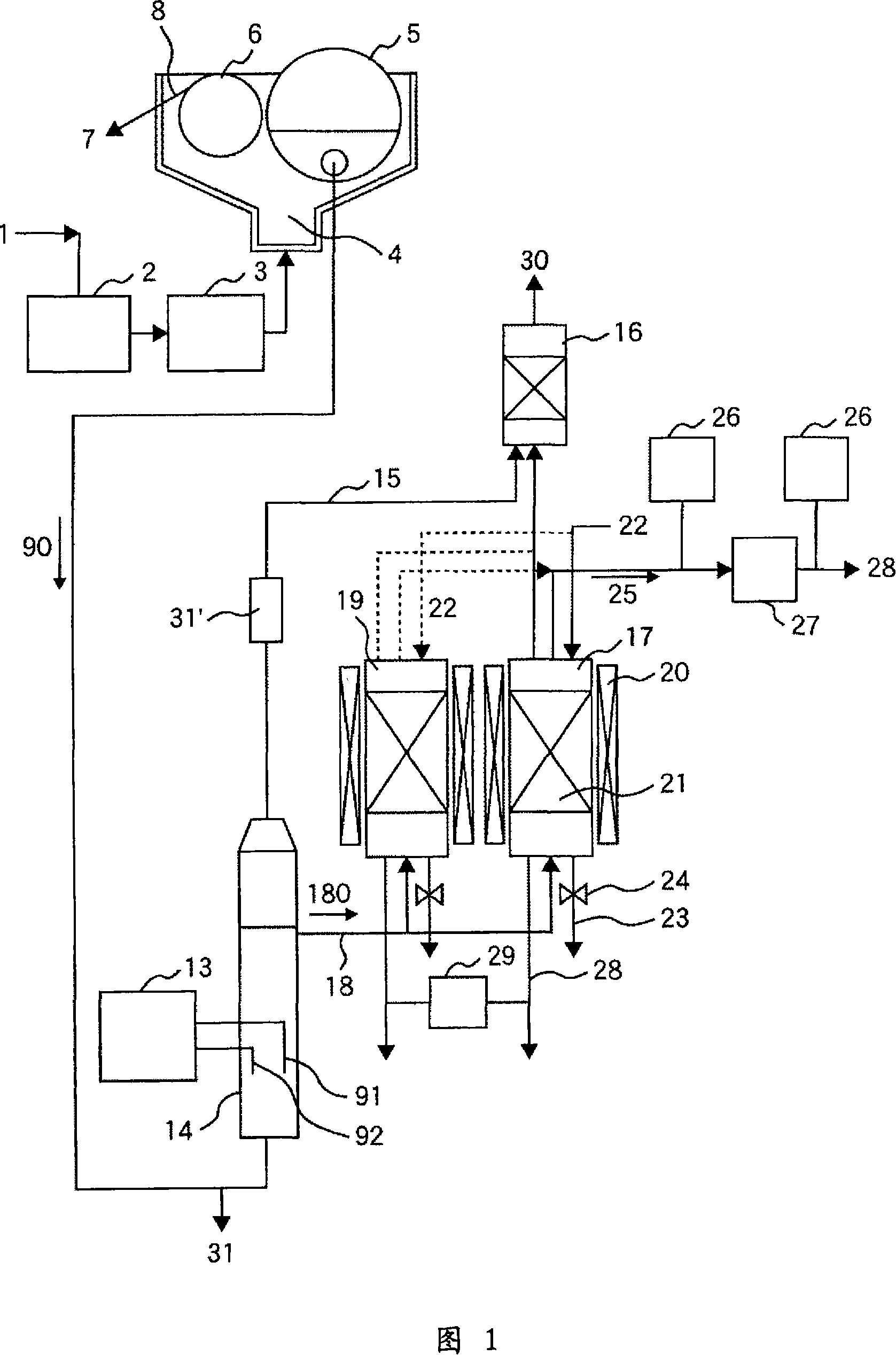

[0087] Hereinafter, one embodiment of the present invention will be described based on FIG. 1 . The wastewater treatment device 10 as an embodiment of the present invention is composed of a magnetic separation device 11 for separating oil from oily water in an oil field, an electrolytic cell 14 , a COD adsorption tank 17 and an exhaust combustion tower 16 .

[0088] The operation of the wastewater treatment device will be described below. First, the oily water 1 of the oil field is installed in the raw water tank 2 . In the oily water of the oil field, the oil is dispersed by emulsification. In addition to organic components and inorganic ions represented by sodium, oily water in oilfields also contains tiny mud, sand and other solid substances. Therefore, the oily water 1 in the oil field is sent to the coagulation tank 3, and a coagulant such as ferric sulfate or polyaluminum chloride and a magnet (Fe 3 o 4 ), γ-hematite (Fe 2 o 3 ) and other magnetic particles, the pr...

Embodiment 2

[0105] Example 2 is an example of test results using the apparatus shown in Example 1.

[0106] Table 3 shows the COD in the electrolysis process and adsorption process Mn value measurement results.

[0107] processing content

COD Mn

propionic acid

1 treatment water

oil-water separation

386

1740

390

-

2 times treated water

270

1200

222

150

3 times treated water

Adsorption treatment

110

410

90

70

[0108] Unit: mg / L

[0109] The primary treated water in Table 3 is the analysis result of sampling in the primary treated water sampling port 31 in FIG. 1 . The secondary treated water is treated by generating an electric field between the electrode 91 and the electrode 92 provided in the electrolytic cell 14 of the electrolytic device 13 using the electric field applying device 13 . ...

Embodiment 3

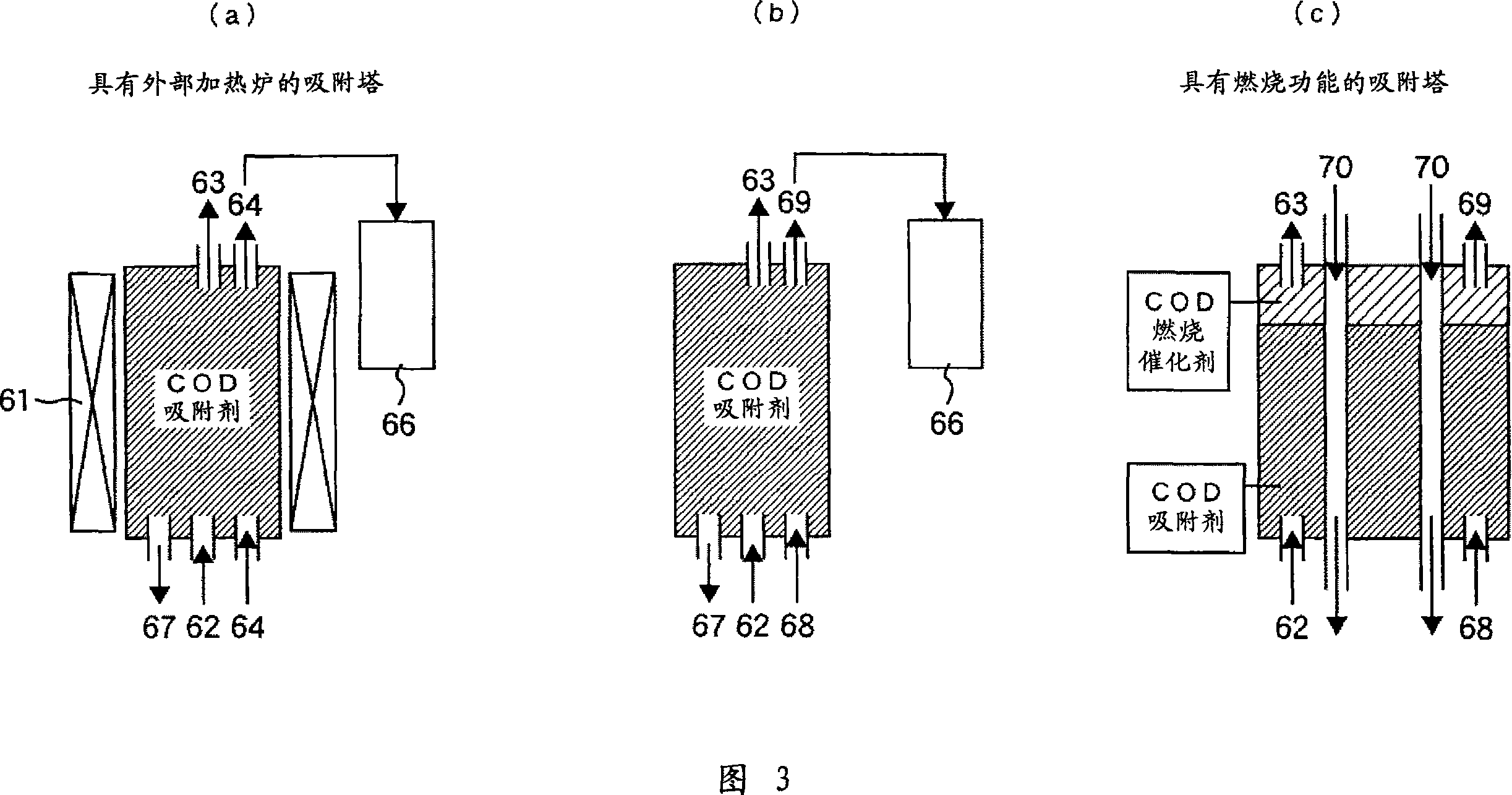

[0121] Example 3 Figure 6 shows the results of regeneration of the adsorbent of the present invention. That is to say, the CO produced by the adsorbent during repeated regeneration 2 , a graph showing the relationship between the amount of CO and hydrocarbons produced and the heating temperature.

[0122] As shown in Figure 6, using adsorbents loaded with various concentrations of catalytic components, the adsorption under the same conditions was carried out, and the temperature-rising detachment test was carried out under the same conditions, and the CO 2 And / or CO gas produces a peak temperature, from which the most suitable catalyst type and concentration range can be determined.

[0123] The experimental conditions used to obtain the results of Fig. 6 are as follows. Use of SiO in Synthetic Zeolite ZSM-5 2 / Al 2 o 3 Zeolite with a ratio of 90 was used as the adsorbent. First, put 5.0 g of the above-mentioned adsorbent into a 200 mL beaker, then put 50 mL of the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com