Firing machine type thermal decomposition furnace

A thermal decomposition furnace and thermal decomposition technology, used in lighting and heating equipment, incinerators, combustion types, etc., can solve the problems of increased equipment costs, insufficient combustion air for cooling, uneconomical, etc., and achieve the effect of improving the carbonization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

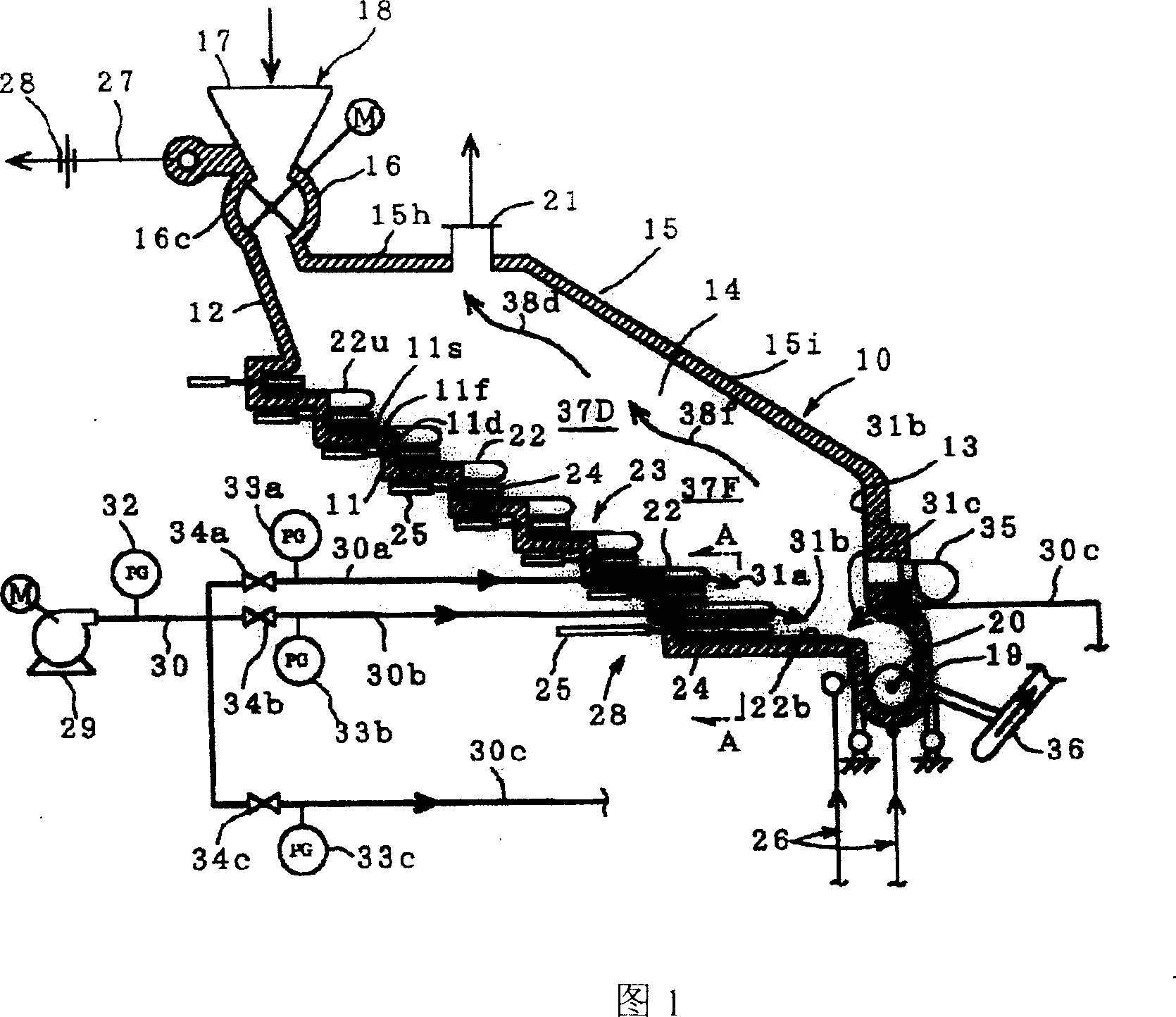

[0026] Embodiments of the present invention will be described below with reference to the accompanying drawings.

[0027] In Fig. 1, 10 is a furnace body formed of refractory material, and a bottom 11 is formed in a step shape, an upper wall 12 is set on the upper section side of the bottom 11, a lower wall 13 is set on the lower section side of the bottom 11, and a bottom wall 13 is set on both sides of the bottom 11. In the side wall 14, the ceiling wall 15 is formed by the inclined wall part 15i and the horizontal wall part 15h from the lower part wall 13 to the upper part wall 12.

[0028] On the ceiling wall 15 on the side of the upper wall 12, a garbage input device 18 composed of a rotary feeder 16 having a casing made of a refractory material and a hopper 17 provided on the rotary feeder 16 is provided. If this garbage input device 18 can drop garbage into the furnace body 10 that does not use the rotary feeder 16 in an airtight state, it can also be configured as, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com