Fireproof panel for shipping

A technology for ships and panels, which is applied in the direction of hull panels, hulls, and hull parts, which can solve problems such as passing through, achieve the effects of preventing deformation and improving fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0137] It is not limited to the fireproof panel of the present invention. When evaluating to meet the A-class fireproof standard or B-class fireproof standard stipulated in the treaty, it is not determined by the structural specifications, but must pass the fire test specified by the International Maritime Organization (IMO) Fire test of the Uniform Code (FTP Code Part 1 and Part 3) (refer to Resolution A.754(18)). Therefore, the fireproof panel of the present invention was trial-manufactured, and implemented the flame corresponding to the A0 standard (irradiated for 60 minutes, without passing through the flame, and the maximum heat radiation Ew was less than 56.5kw / m 2 case) fire test.

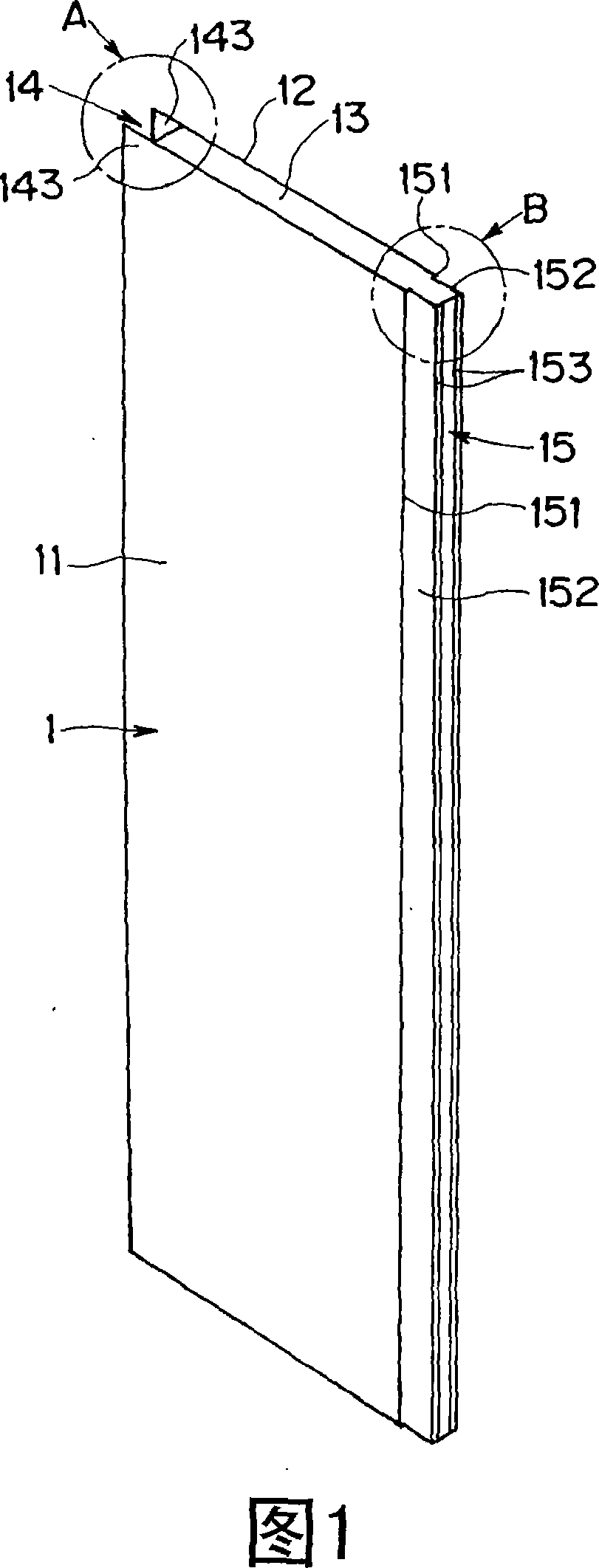

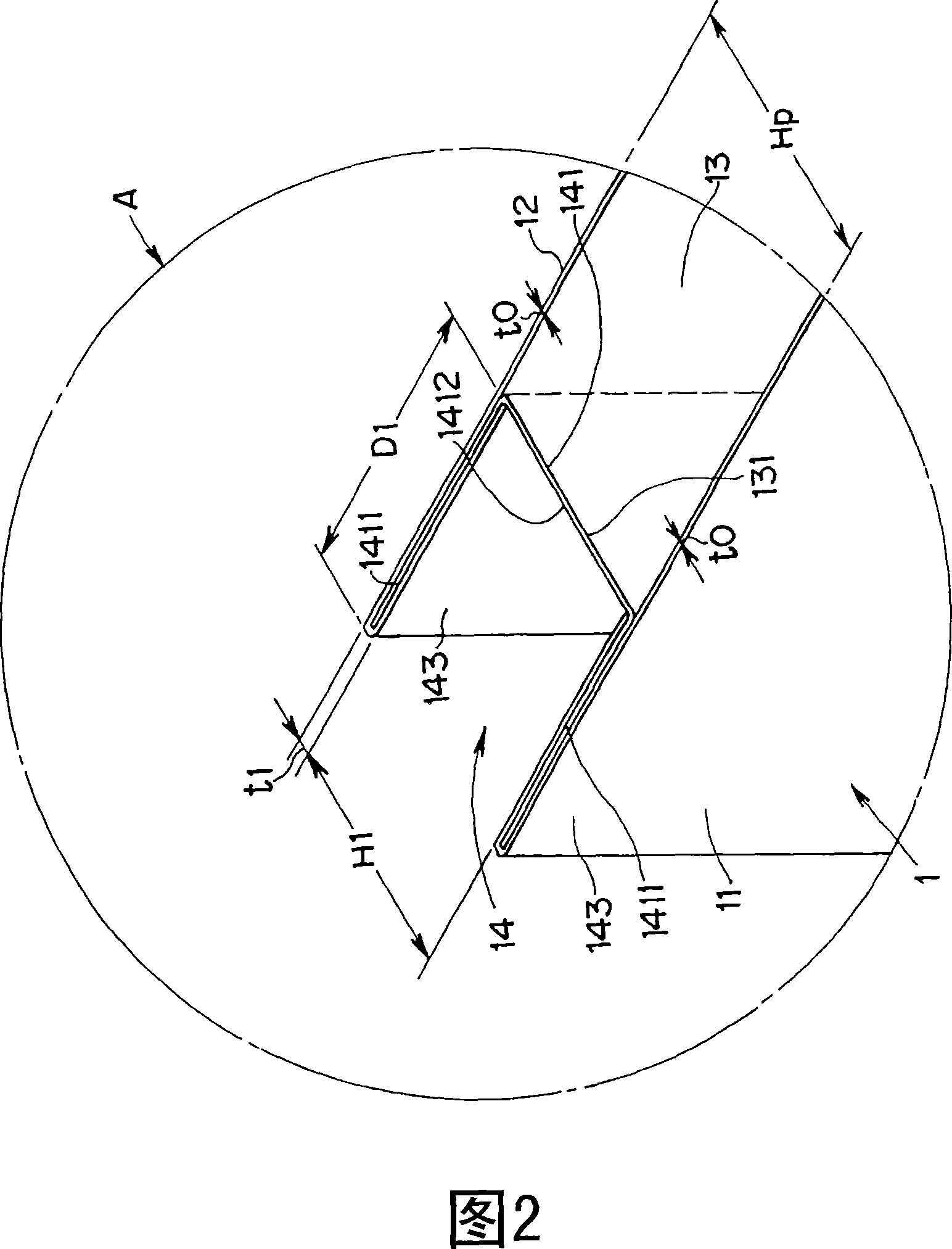

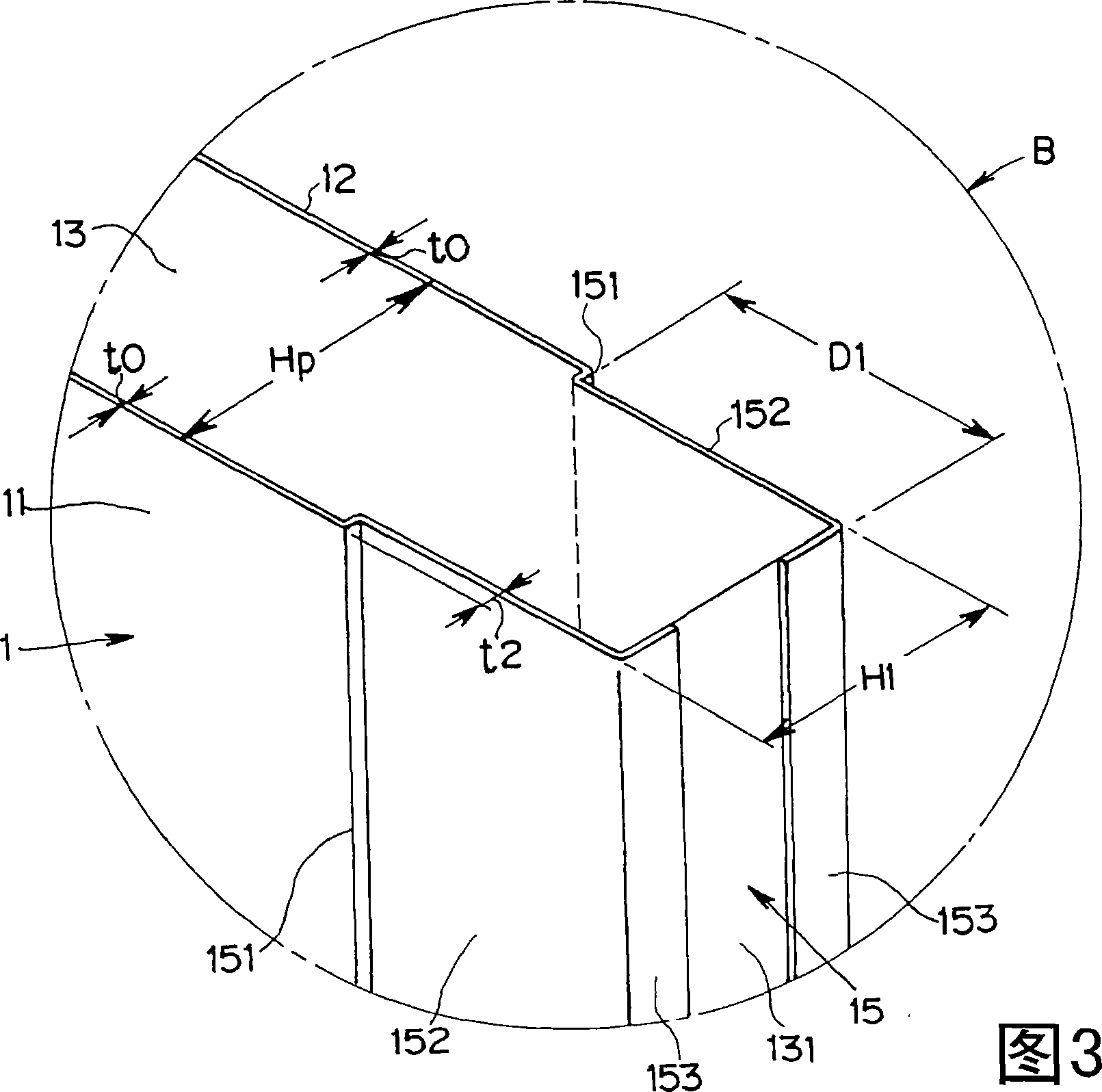

[0138] The test body is composed of 4 pieces of the above-mentioned exemplified (refer to FIG. 1 ) fireproof panels 1 in a roughly square test frame to form a wall surface, and the flame is irradiated from the front (outer panel) side of the above-mentioned wall surface through a gas burner....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com