Overhead high speed train

A technology for high-speed trains and trains, applied to motor vehicles, elevated railways, railway vehicles, etc., can solve the problems of unfavorable popularization, complex structure, high overhead catenary construction and maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

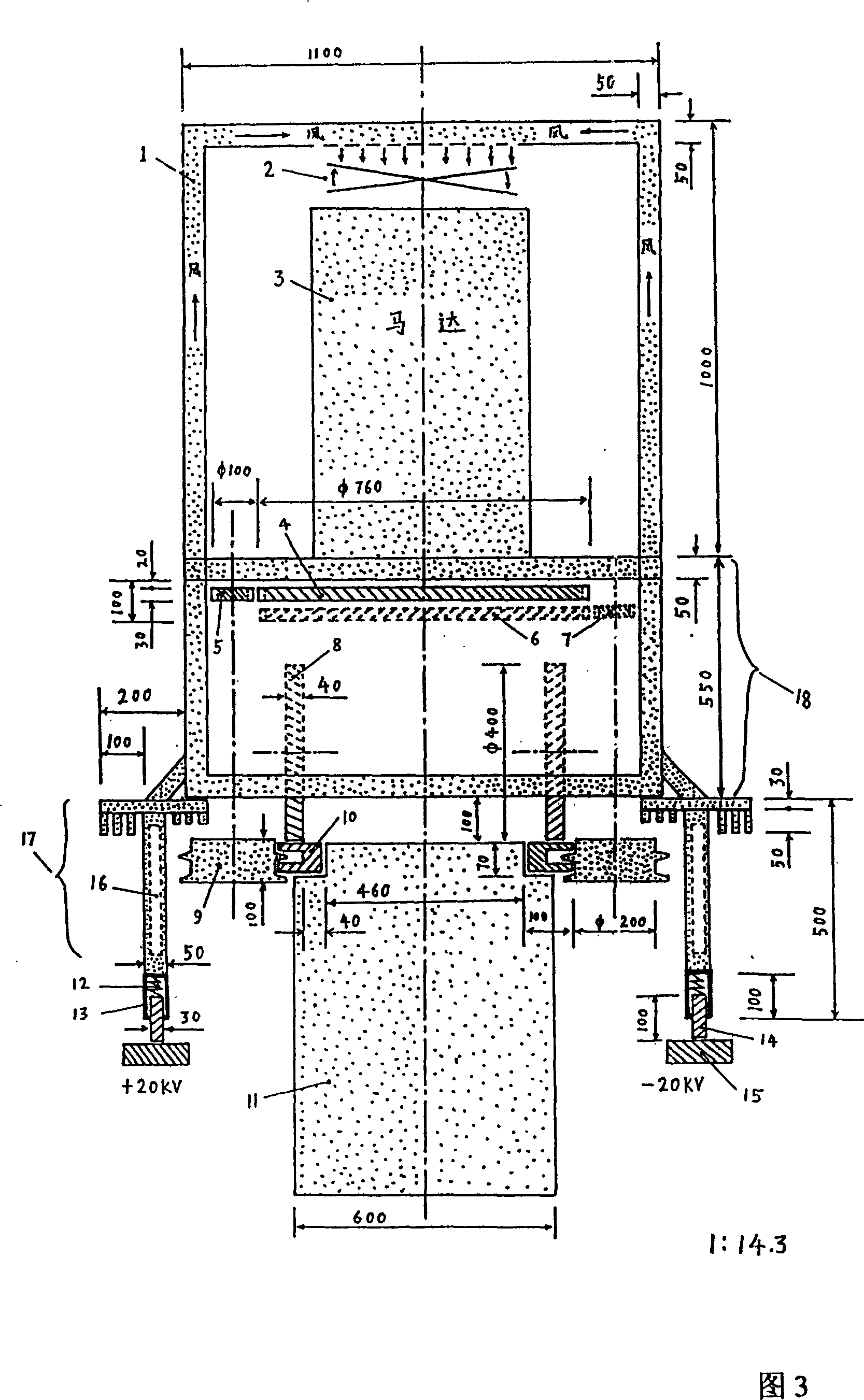

[0328] Since this new type of overhead high-speed train involves power transmission system, train system, control and communication system, overhead track system, parking station system, and other auxiliary systems, it is necessary to complete the above-mentioned six major systems and interact with each other in order to realize this high-speed train. To coordinate well. The main implementation process is as follows: (1) Establish the mathematical model of the high-speed train, and use the computer to calculate the relevant important parameters, such as air resistance, friction resistance, high-speed vibration and various conditions (such as bending, changing rails, uphill, downhill) etc.) force and so on. Determine the total power size, shape and structure of the high-speed train through these parameters, so as to design the prototype of the high-speed train. (2) Conduct a wind tunnel simulation test on a small section of the designed high-speed train to verify relevant impo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com