Automatic protective mechanism of sharpener for tip of pencil

An automatic protection and pencil sharpener technology, which is applied in sharpening devices, printing, office supplies, etc., can solve problems such as pen tip thickness adjustment errors, and achieve the effect of simple and compact structure, small inertia, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

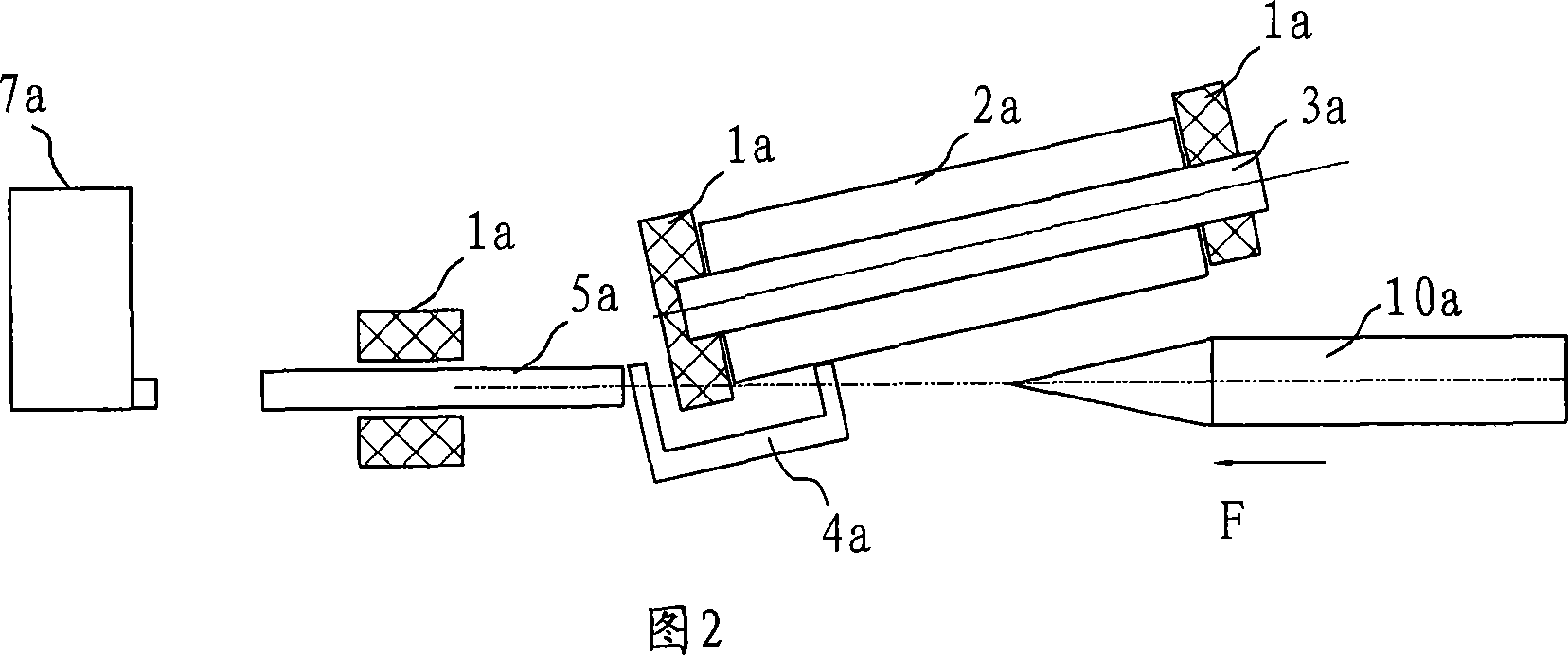

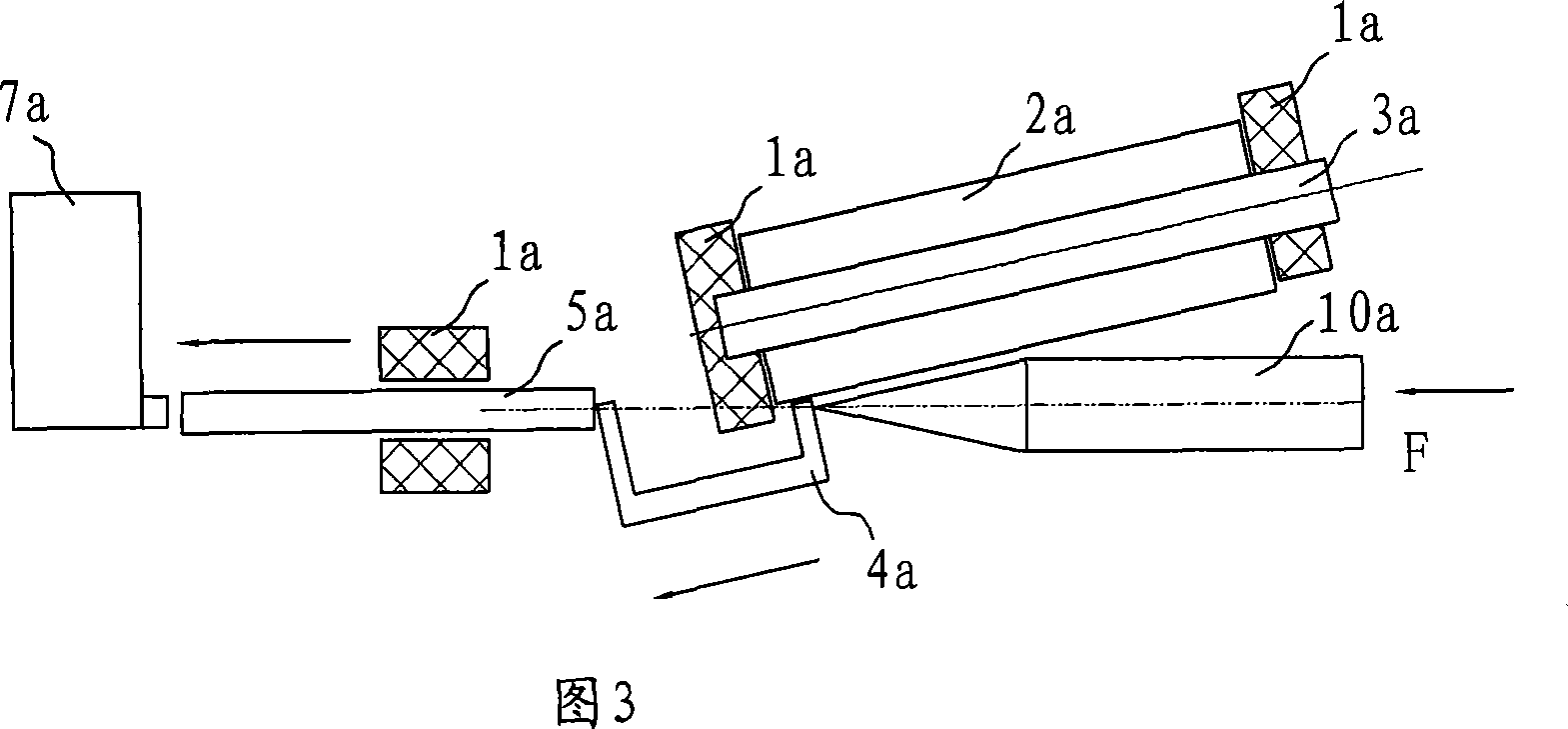

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] Embodiment, refer to Fig. 4 and Fig. 5.

[0030] The automatic protection mechanism for the tip of the pencil sharpener in this embodiment includes a hob assembly 2, a knife rest 1, a counterweight 6, a knife shaft 3, a slider 4, a control rod 5, a rotating handle 8 and a reset mechanism 9.

[0031] The hob assembly 2 can be driven by a power source to rotate, and its peripheral wall has a helical blade, and its rear end and knife rest 1 junction are also provided with a ring-shaped dust-proof element 21, which can be made of sponge.

[0032] The knife holder 1 has a tapered cavity 11 for inserting a pencil 10 , and a long cutting hole matched with the hob assembly 2 is provided on its side.

[0033] The cutter shaft 3 is used to drive the hob assembly 2 to rotate. It is passed through the hob assembly 2 and mounted on the tool holder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com