Golf club head with porous material and its making method

A technology of golf head and manufacturing method, which is applied to golf balls, golf clubs, rackets, etc., can solve the problems of unobtainable porosity, difficult mass production, and difficult weight control, and achieve weight reduction, shortening process time, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The golf head with porous material and its manufacturing method of the present invention will be described in detail below through preferred embodiments and accompanying drawings. Before the present invention is described in detail, it is noted that in the following description, similar elements are denoted by the same numerals.

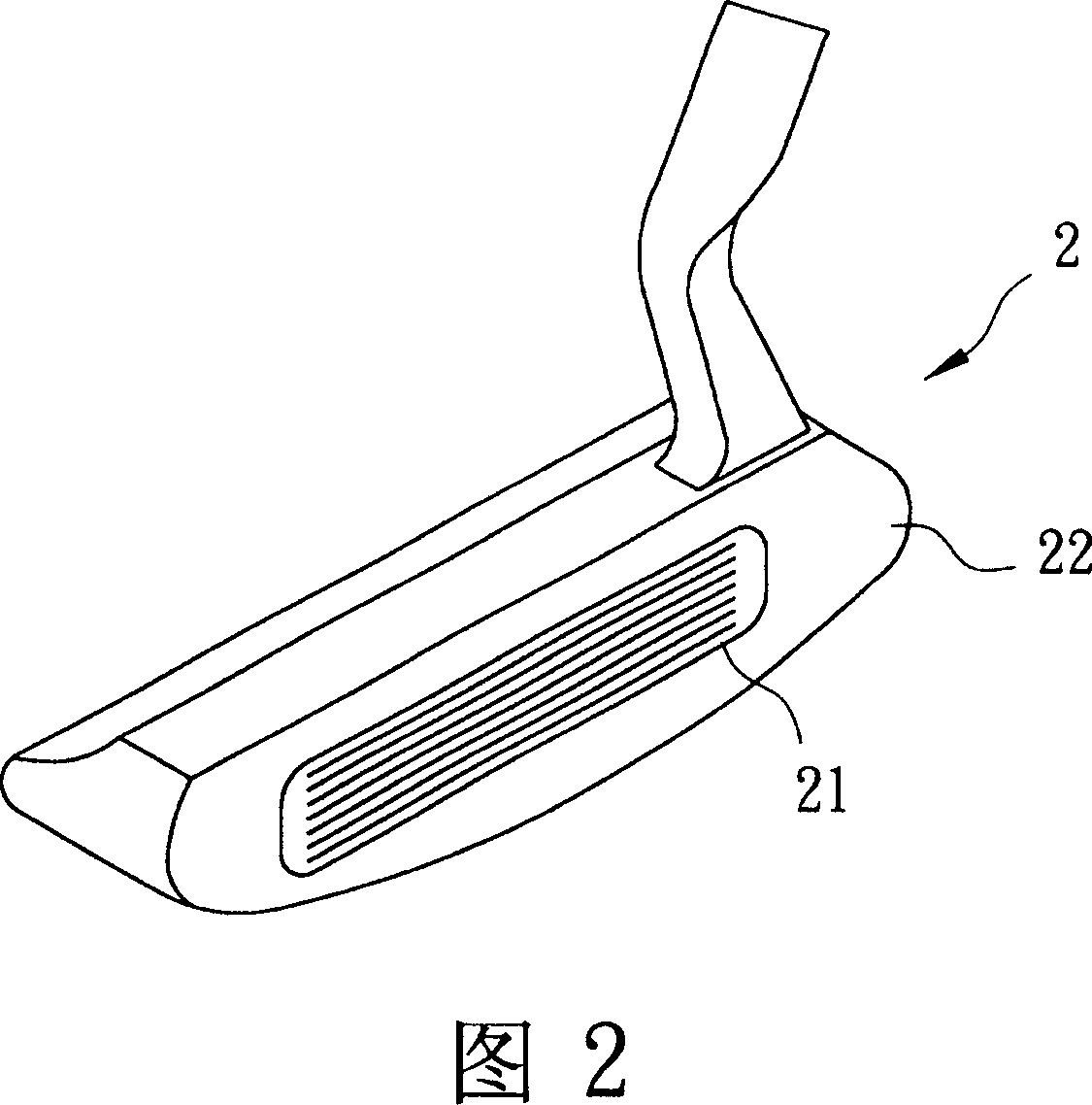

[0020] As shown in Fig. 2 and Fig. 3, the first preferred embodiment of the golf head 2 with porous material of the present invention includes a first component 21, a second component 22 that can be combined with the first component 21 .

[0021] The second component 22 has a porous main body 221 made of a porous material, an inner covering layer 222 covering the surface of the porous main body 221, and a carbon fiber covering the surface of the inner covering layer 222. The outer cladding layer 223 made of material.

[0022] In the first preferred embodiment, the golf head 2 belongs to the type of a putter head (Putter Head), the first comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com