Electrically heated cigarette including controlled-release flavoring

A technology of electric heating and flavoring agent, which is applied in the direction of tobacco, tobacco pipe, and processed tobacco, etc. It can solve the problems of reducing the activity of adsorbents, the uniformity of flavored cigarettes is not completely satisfactory, and the ability to reduce gas phase components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

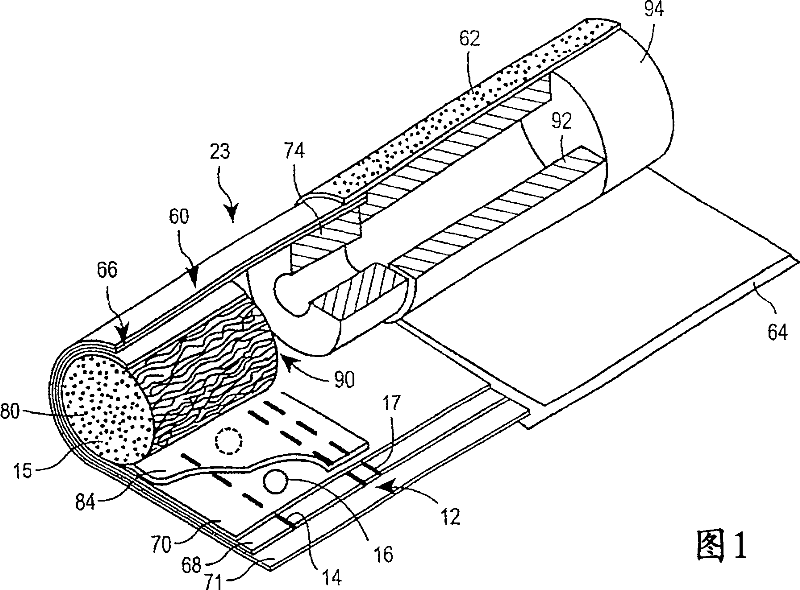

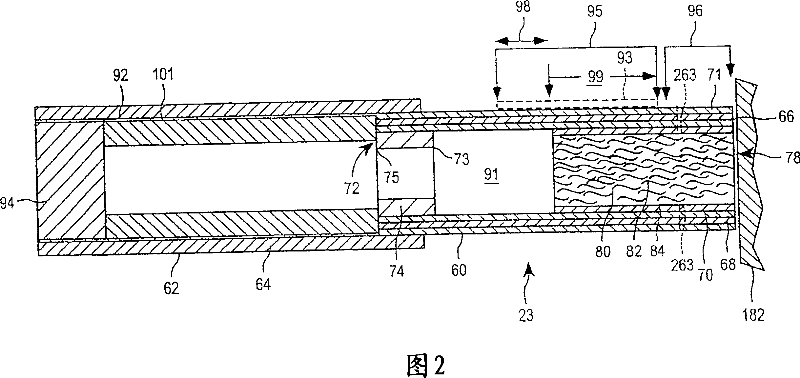

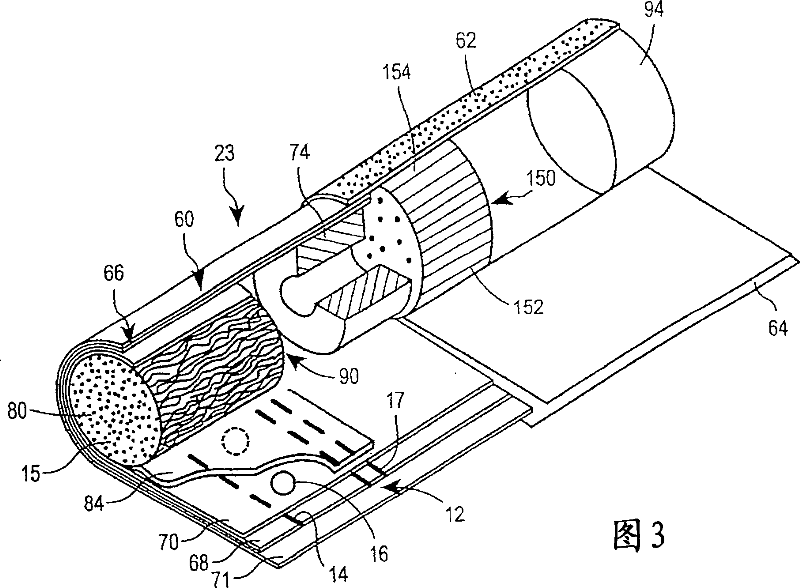

[0023] The electrically heated cigarette includes one or more sorbents and at least one flavoring agent for affecting the smell, taste and / or aroma of tobacco smoke. In a preferred embodiment, the flavoring is incorporated into the cigarette in a flavor release additive which preferably reduces the release and / or migration of the flavoring within the tobacco prior to smoking. Preferably, the flavor is released from the flavor release additive in a controlled manner during smoking. The flavor release additive allows the flavor to enhance the subjective characteristics of the cigarette without adversely affecting the effectiveness of the sorbent in removing selected gas phase components from mainstream smoke.

[0024] In a preferred embodiment of an electrically heated cigarette, the flavor releasing additive releases the flavor once heated to at least one minimum temperature (flavor release temperature), which occurs when the smoker draws mainstream smoke through the cigarette....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com