Safety excess flow valve for gas conduits

A gas pipeline, automatic closing technology, used in safety valves, pipe components, valve details, etc., can solve problems such as expensive, and achieve the effect of increasing distance and accurate guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

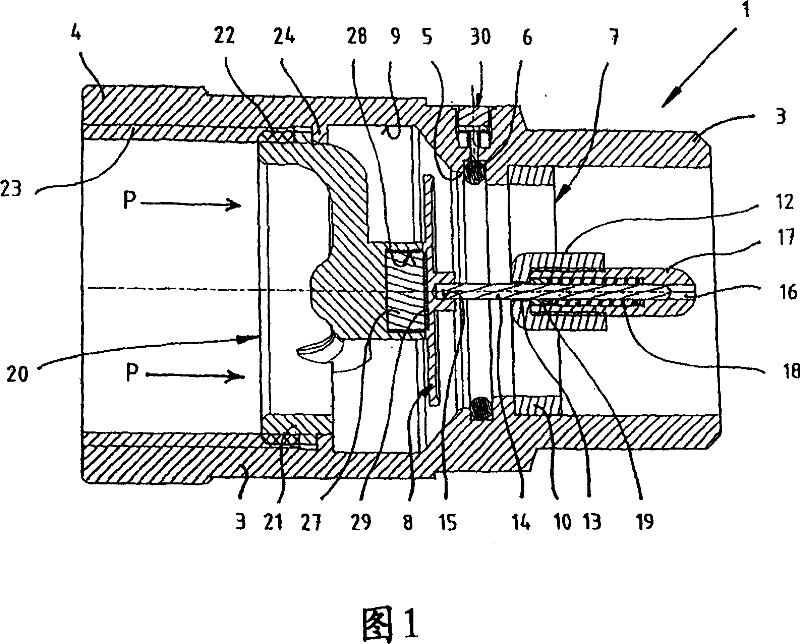

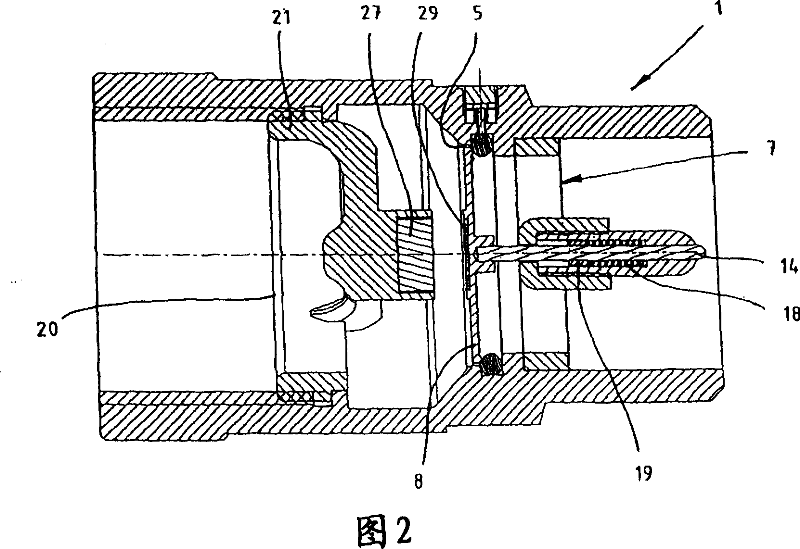

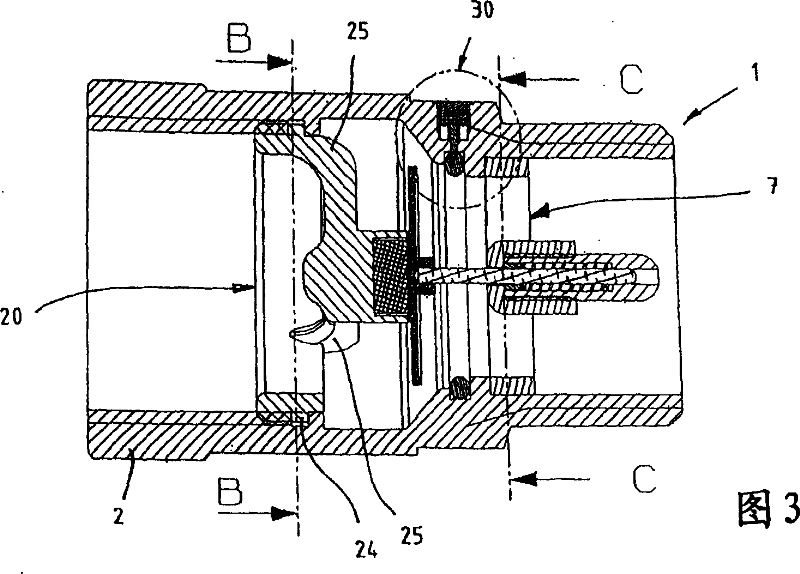

[0020] Figure 1 depicts a safety valve 1 arranged to be screwed into a gas line. For this purpose, the safety valve 1 is provided at its ends with a housing 2 of threaded connections 3 , 4 . The flow direction of the gas is indicated by arrow P. Inside the housing 2 is arranged a valve seat 5 with a sealing ring 6 which is inserted in a circumferential groove of the housing 2 . A guide bridge 7 is inserted into the housing 2 in the flow direction behind the valve seat 5 , which guide bridge 7 guides a closing body 8 which can be displaced relative to the guide bridge 7 . The closing body 8 can be moved in the direction of the valve seat 5 and can close the gas line when the maximum flow rate is exceeded. The closure body 8 shown in FIG. 1 is in the open position. The closure body 8 shown in FIG. 2 is in the closed position. If the closing body 8 is in the open position, gas can flow around the closing body 8 so that the gas can pass the valve seat 5 . If the fluid flow ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com