Control method of liquid level in autoclave for fluothane hydrocarbon production

A control method and technology of kettle liquid level, which is applied in the direction of halogenated hydrocarbon preparation, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problems of liquid level measurement deviation, leakage, operation error, etc., and achieve accurate control of liquid level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

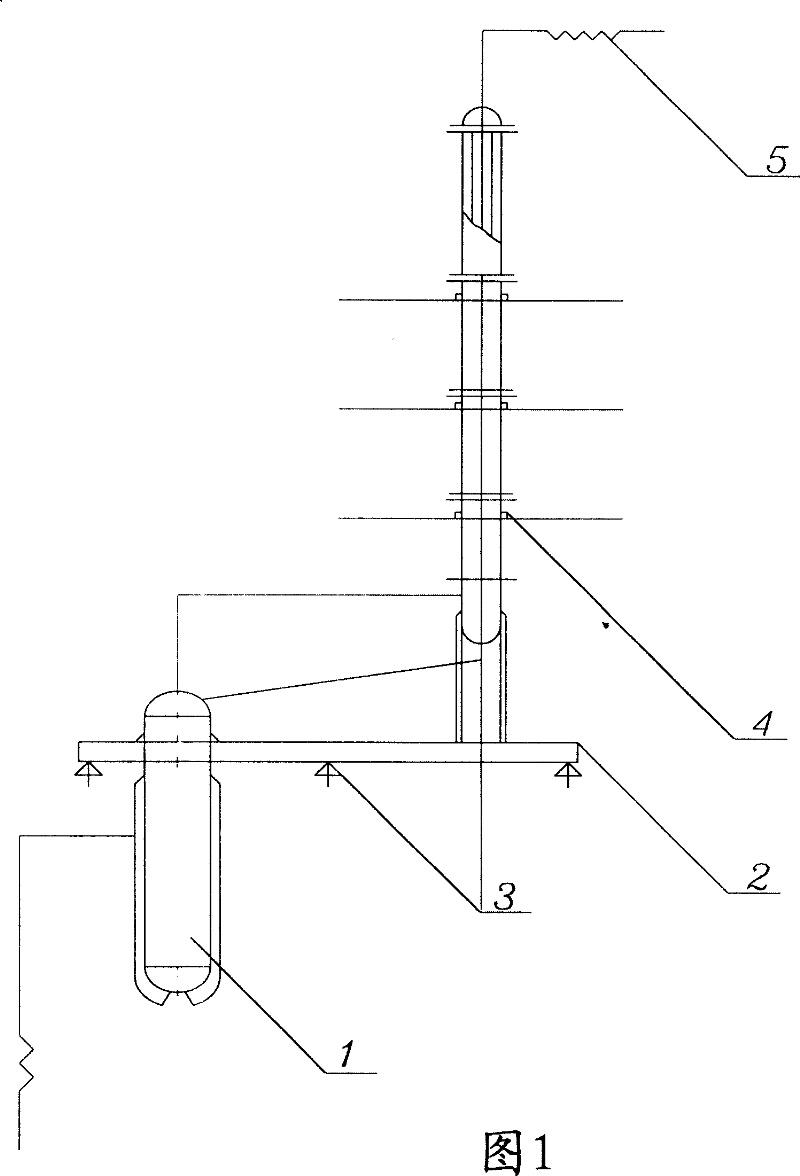

[0012] The reaction kettle 1 and the reactive distillation tower 2 are integrally supported on a rectangular movable platform with a steel structure, and six 5-10 ton electronic weighing modules 3 are respectively placed in the four corners and the middle of the platform, and the reactive distillation tower 2 is respectively electronically scaled. The weighing module 3 is fixed on the movable guide rails 4 on the platforms of each layer to ensure free movement up and down, and the relevant pipelines adopt soft connections 5 . The collected signal is displayed on site and transmitted to the DCS system in the control room through remote transmission to reflect the actual weight of the reactor in time, so that the operator can understand the liquid level of the reactor and control the operation to ensure the smooth operation of the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com