Mobile nursery etock transplanter

A transplanting machine, self-propelled technology, applied in the direction of transplanting machinery, planting methods, fertilization devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

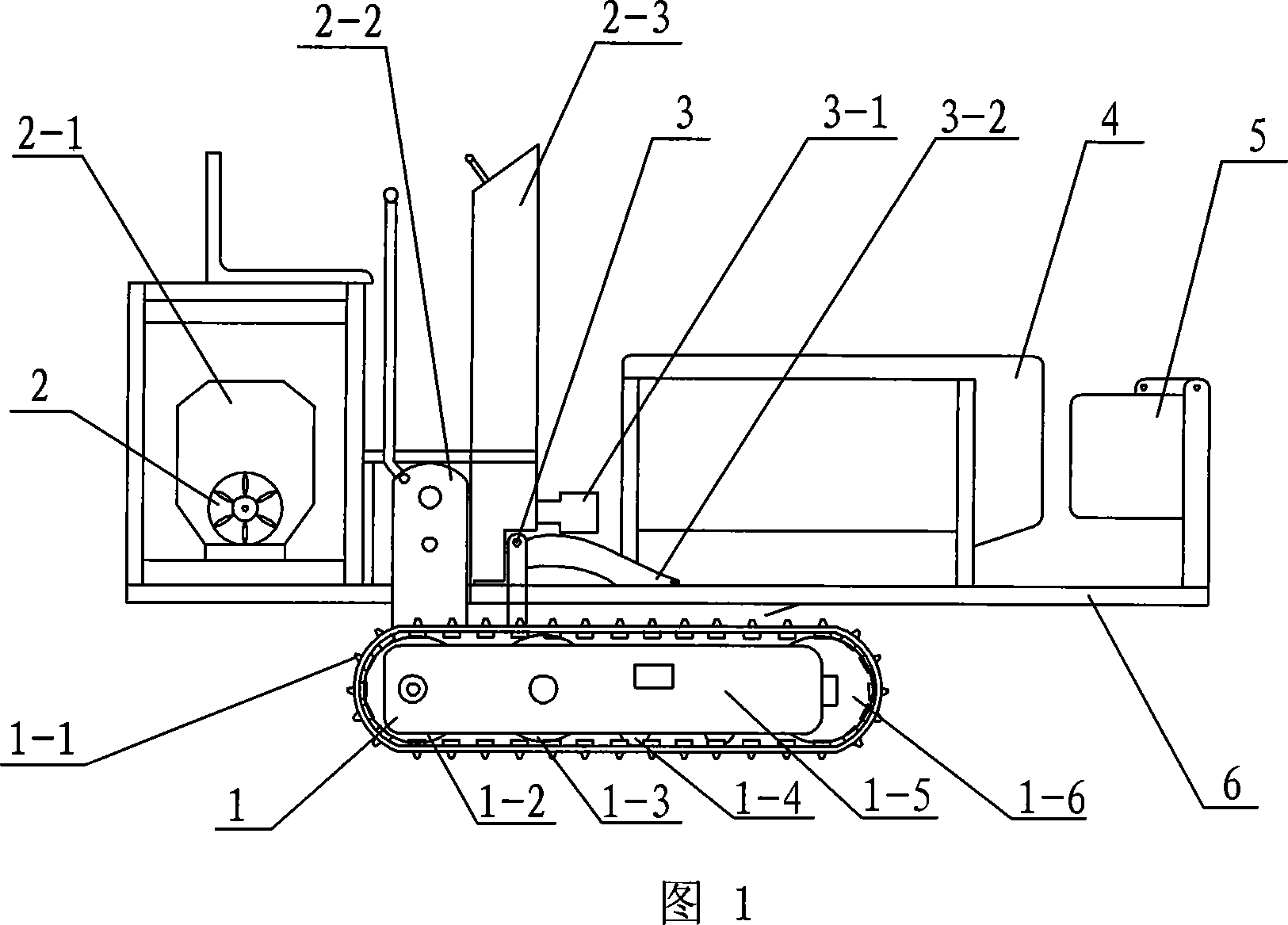

[0005] Specific embodiment one: (see Fig. 1) this embodiment is made up of crawler belt traveling device 1, power and transmission control system 2, suspension device 3, seedling transplanting operation device 4, seat and seedling storage box 5 and mainframe 6, crawler belt The traveling device 1 is composed of a crawler belt 1-1, a driving wheel 1-2, a large supporting wheel 1-3, a small supporting wheel 1-4, a walking frame 1-5 and a guide tensioning wheel 1-6, power and transmission control System 2 is composed of gasoline or diesel engine 2-1, gearbox 2-2 and console 2-3, suspension device 3 is composed of hydraulic lifting device 3-1 and four-bar suspension frame 3-2, and driving wheel 1-2 is set At the rear end of the walking frame 1-5, the guide tensioning wheel 1-6 is arranged on the front end of the walking frame 1-5, and the large supporting roller 1-3 and the small supporting roller 1-4 are arranged on the driving wheel 1-2 respectively. On the walking frame 1-5 bet...

specific Embodiment approach 2

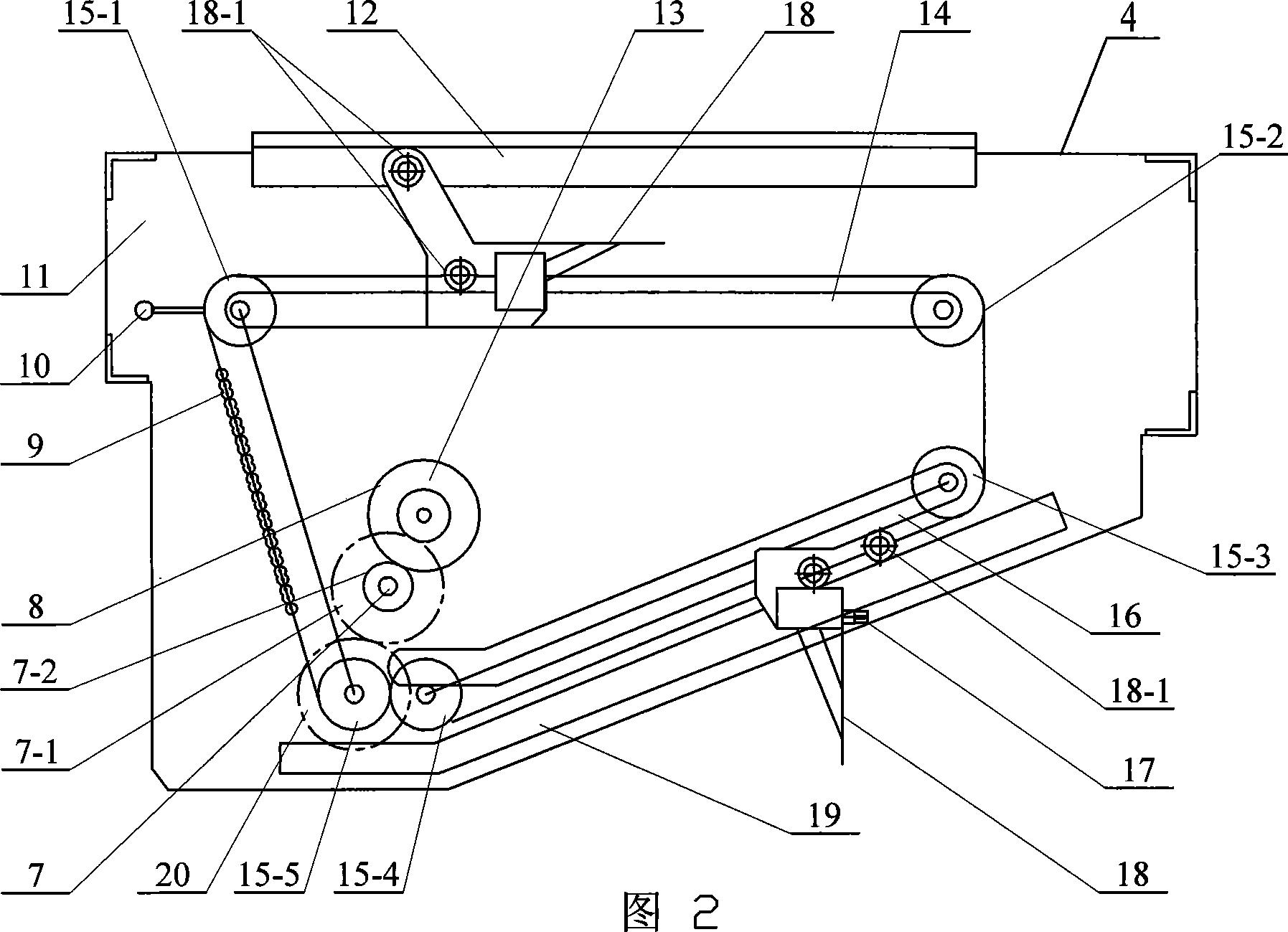

[0006] Specific embodiment two: (referring to Fig. 2) seedling transplanting operating device 4 of the present embodiment is made up of transition synchronous device 7, drive gear 8, chain 9, turnover mechanism 10, frame 11, upper flat rail 12, drive motor 13, lower flat Rail 14, first sprocket 15-1, second sprocket 15-2, third sprocket 15-3, fourth sprocket 15-4, fifth sprocket 15-5, upper inclined rail 16, straight bar Type seedling clamping device 17, ditch opener 18, lower inclined rail 19 and gear 20, upper flat rail 12 is fixed on the upper end of frame 11, lower flat rail 14 and upper flat rail 12 are fixed under upper flat rail 12 in parallel with each other On the frame 11 on the side, the lower ramp 19 is fixed on the lower end of the frame 11, and the upper ramp 16 is fixed on the frame 11 on the upper side of the lower ramp 19 in parallel with the lower ramp 19. The first sprocket wheel 15-1 Be arranged on the frame 11 at the left end of the lower flat rail 14, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com