Socket for semiconductor apparatus

A socket and semiconductor technology, applied in the direction of coupling device, connection, fixed connection, etc., can solve the problems of affecting the signal transmission between the chip and the circuit board, the falling off of the C-shaped spring, and the small contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

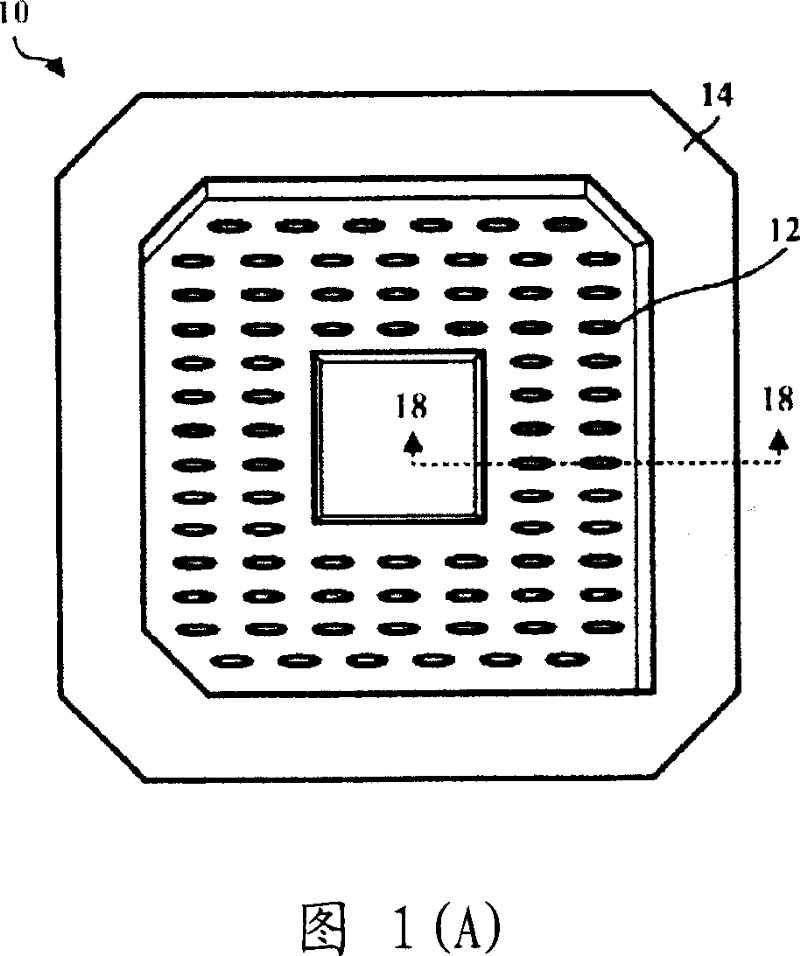

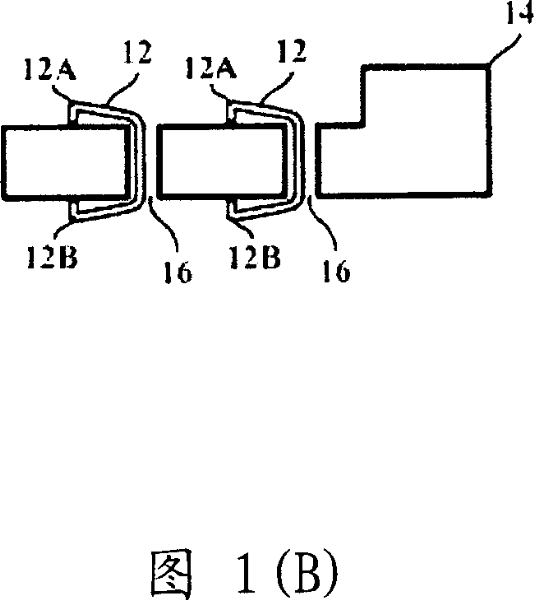

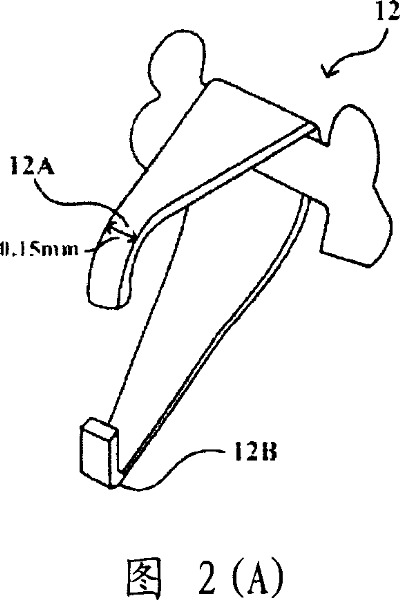

[0020] One of the main objectives of the present invention is to provide a socket for electrically connecting a chip and a circuit board. The chip includes at least one conductive end, the circuit board includes at least one contact point, and the contact point of the circuit board corresponds to the conductive end of the chip.

[0021] The first preferred embodiment according to the present invention is a socket. Please refer to Figure 3(A). FIG. 3(A) is a schematic diagram of the socket 30 . The socket includes a substrate 34 and at least one conductive post 32 . The substrate 34 further includes at least one hole 36 penetrating through the substrate 34 . Conductive posts 32 are placed through holes 36 . When the socket 30 is placed between the chip and the circuit board, a first end 32A of the conductive post 32 is in contact with the conductive end, and a second end 32B of the conductive post 32 is in contact with the conductive end. The corresponding contact points a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com