Non-stopping paper feeding device for offset press

A technology of paper feeding device and offset printing machine, applied in printing machines, general parts of printing machinery, printing, etc., can solve the problems of minimizing color difference, affecting printed products, printing without stopping, etc., and achieve the effect of improving color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

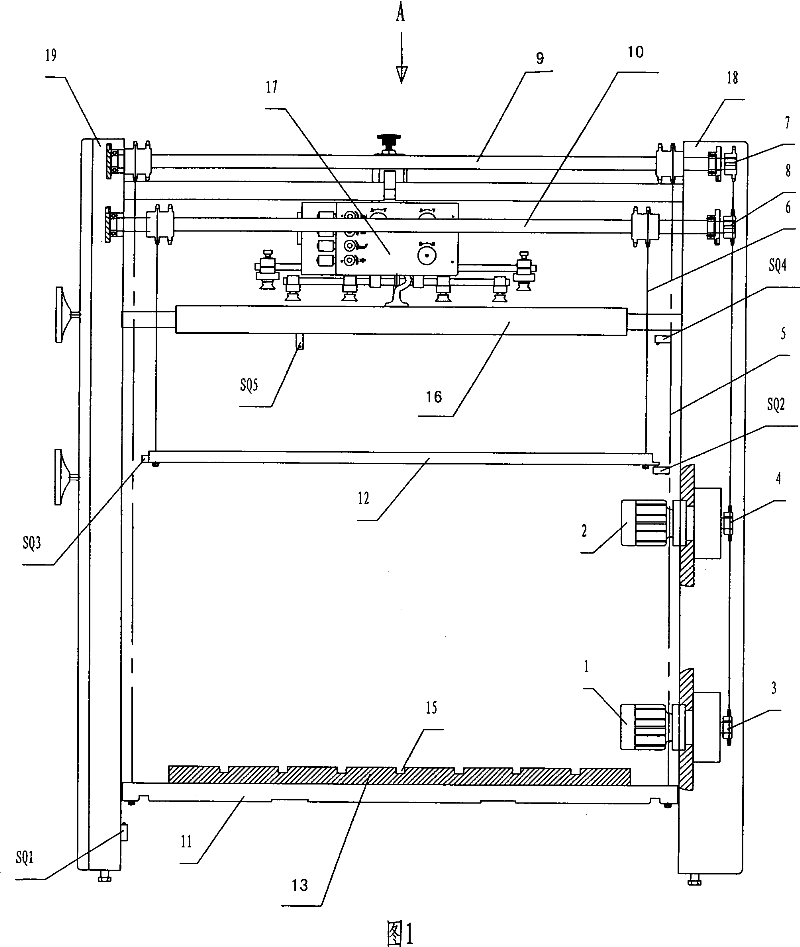

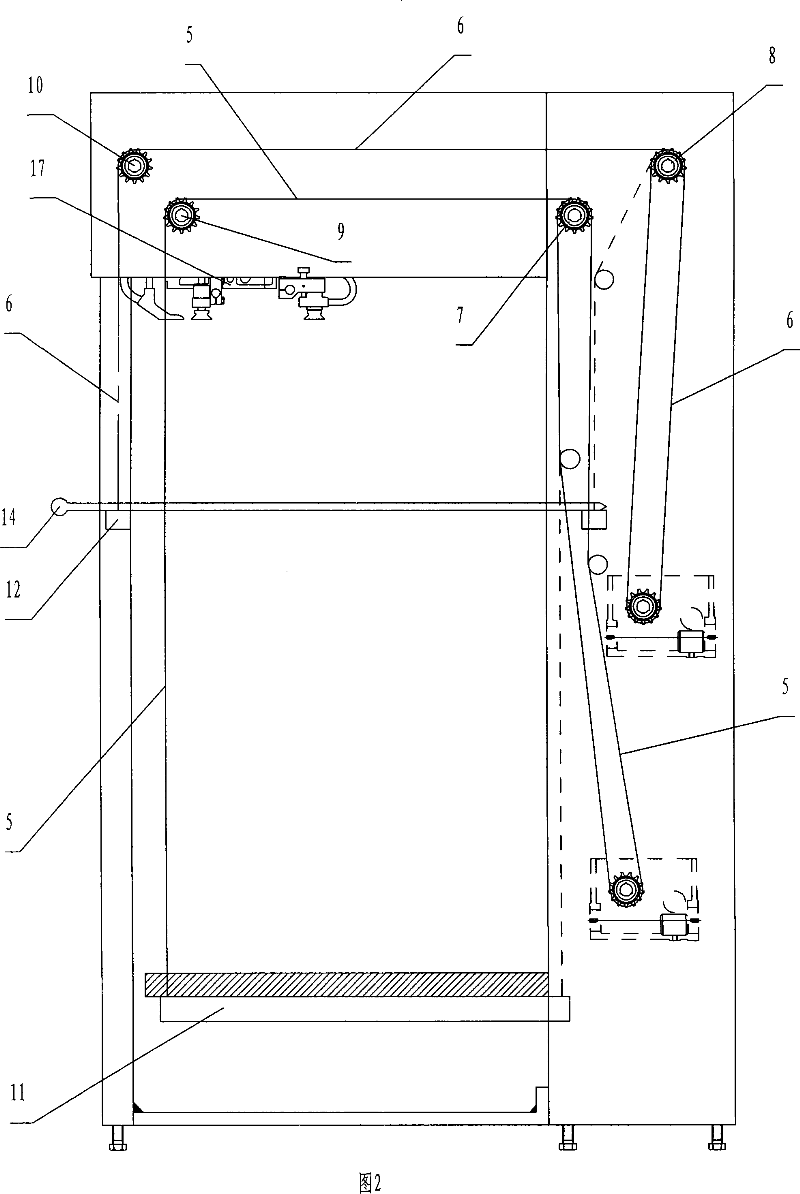

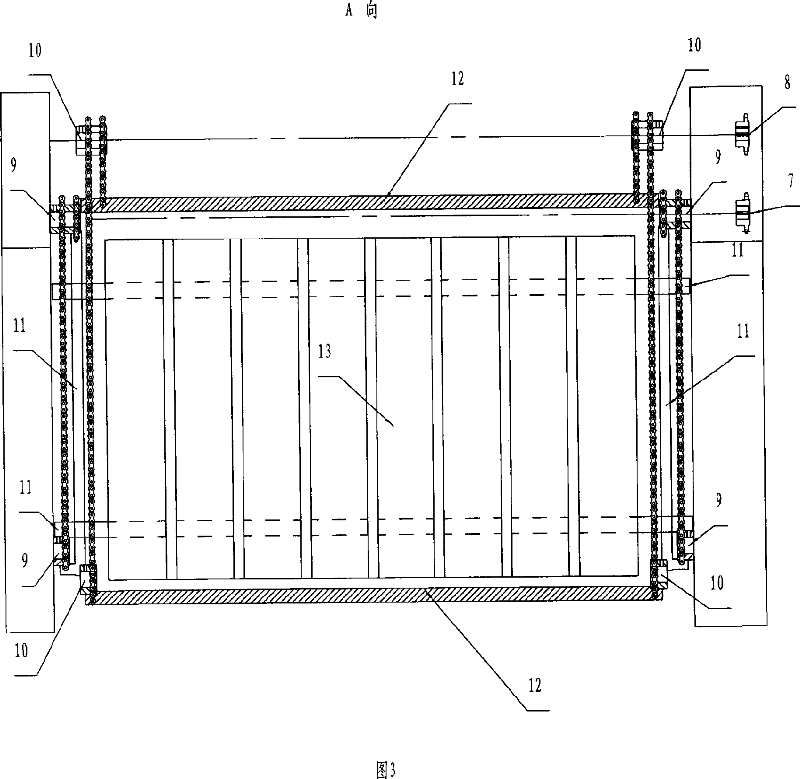

[0013] The basic structure of the present invention is shown in Fig. 1, 2, and paper feeding machine is made up of main and auxiliary stacking table and main and auxiliary transmission device, and drive wheel 3 is connected on the output shaft of main motor 1, through main transmission chain 5, transmission wheel 7 and The transmission rod 9 drives the main stacking frame 11, the output shaft of the auxiliary motor 2 is connected with the secondary driving wheel 4, and the secondary stacking frame 12 is driven by the transmission chain 6, the transmission wheel 8 and the transmission rod 10. The main paper stacker 11 is a rectangle whose four corners on both sides are respectively hung on the end of the main drive chain 5 for fastening. The two ends on both sides of the auxiliary paper stacker 12 are respectively hung on the ends of the auxiliary transmission chain 6 for fastening. The main stacking frame 11 is arranged on the lower half of the left and right frames 19, 18 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com