Knife assembly sheet disintegrator

A technology of combining knives and pulverizers, which is applied in agricultural machinery and implements, cutting equipment, applications, etc., can solve the problems of unsatisfactory straw pulverizing work efficiency, short tool life, small processing quantity of materials, etc., achieving low noise and pulverization. High efficiency and adjustable cutting length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

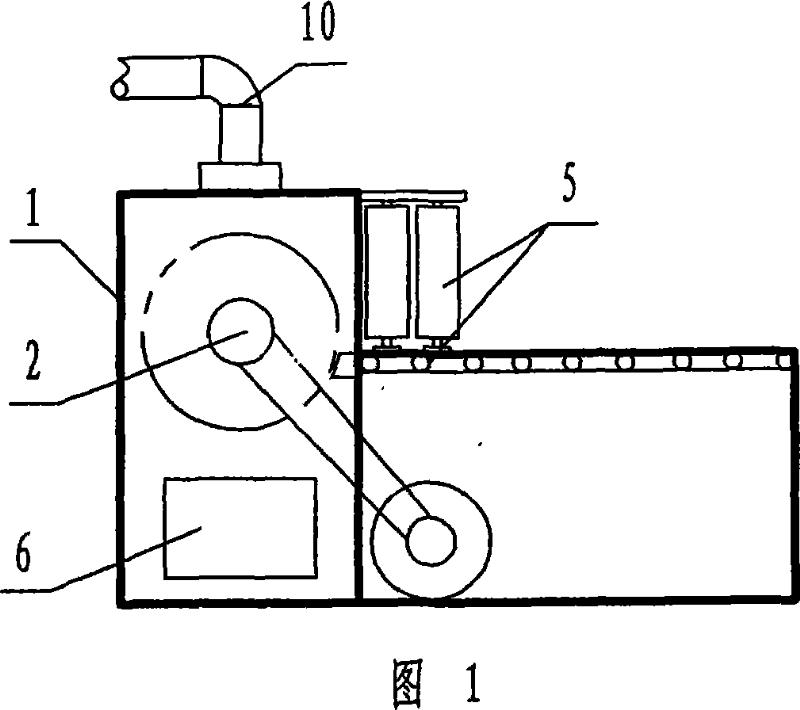

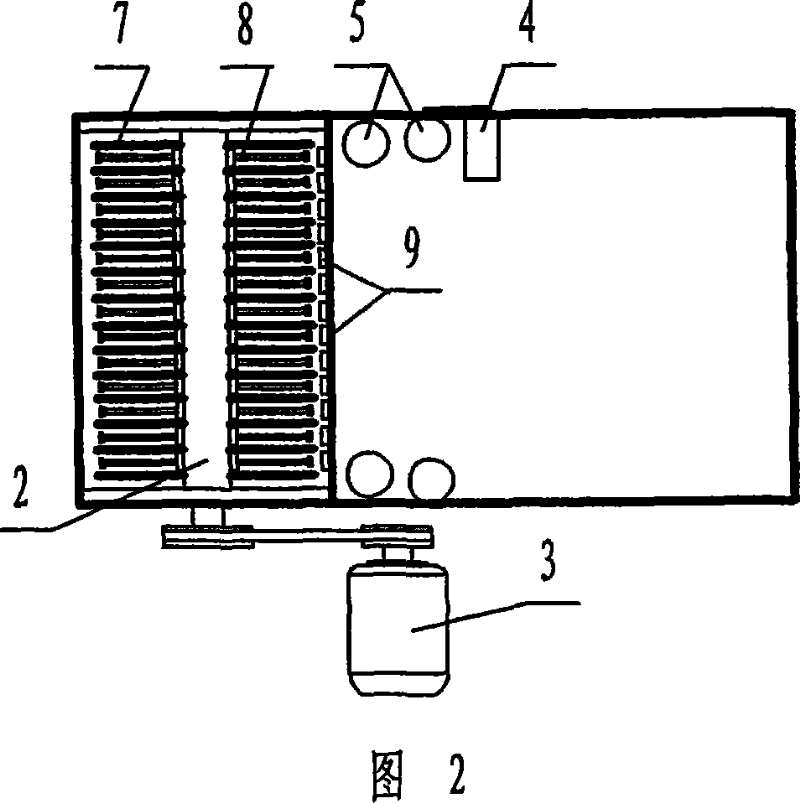

[0009] Embodiment 1, disc combination cutter pulverizer, comprises frame shell 1, cutter and main shaft 2, feeding device 5 and its reducer drive 4, and main shaft 2 is fixed on the two ends of frame shell 1, by frame The motor 3 outside the housing 1 is driven. The cutter is composed of a set of disc-type moving knives 7, a set of fixed knives 9, and a set of chopping knives 8. The disc-type moving knives 7 are installed on the main shaft 2 in parallel. There are several chopping knives 8 installed on the main shaft 2 between the slice-type moving knives 7, and fixed knives 9 arranged in parallel are fixed on the corresponding frame housing 1 separated from the disc-type moving knives 7 and chopping knives 8, The piece-type movable knife 7 and the fixed knife 9 are installed in a staggered shape, and a discharge chute 6 is provided at the bottom of the frame housing 1, and a dust collection system 10 is provided at the top.

Embodiment 2

[0010] Embodiment 2, with reference to Embodiment 1, the number of adjacent disc-type moving knives 7 installed on the main shaft 2 is set according to needs, with 1-60 being commonly used, the knives installed on the disc-type moving knives 1 The head is a quick mouth cutter head or a wide particle regeneration cutter head or other conventional cutter heads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com