Method for packing the adhesive tape at the bottom of the lithium ion battery coil core and its device

A lithium-ion battery and tape-packing technology, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, and electrolyte batteries, can solve problems such as potential safety hazards and affect the quality of battery products, and achieve improved quality, good effects, and simple operation processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

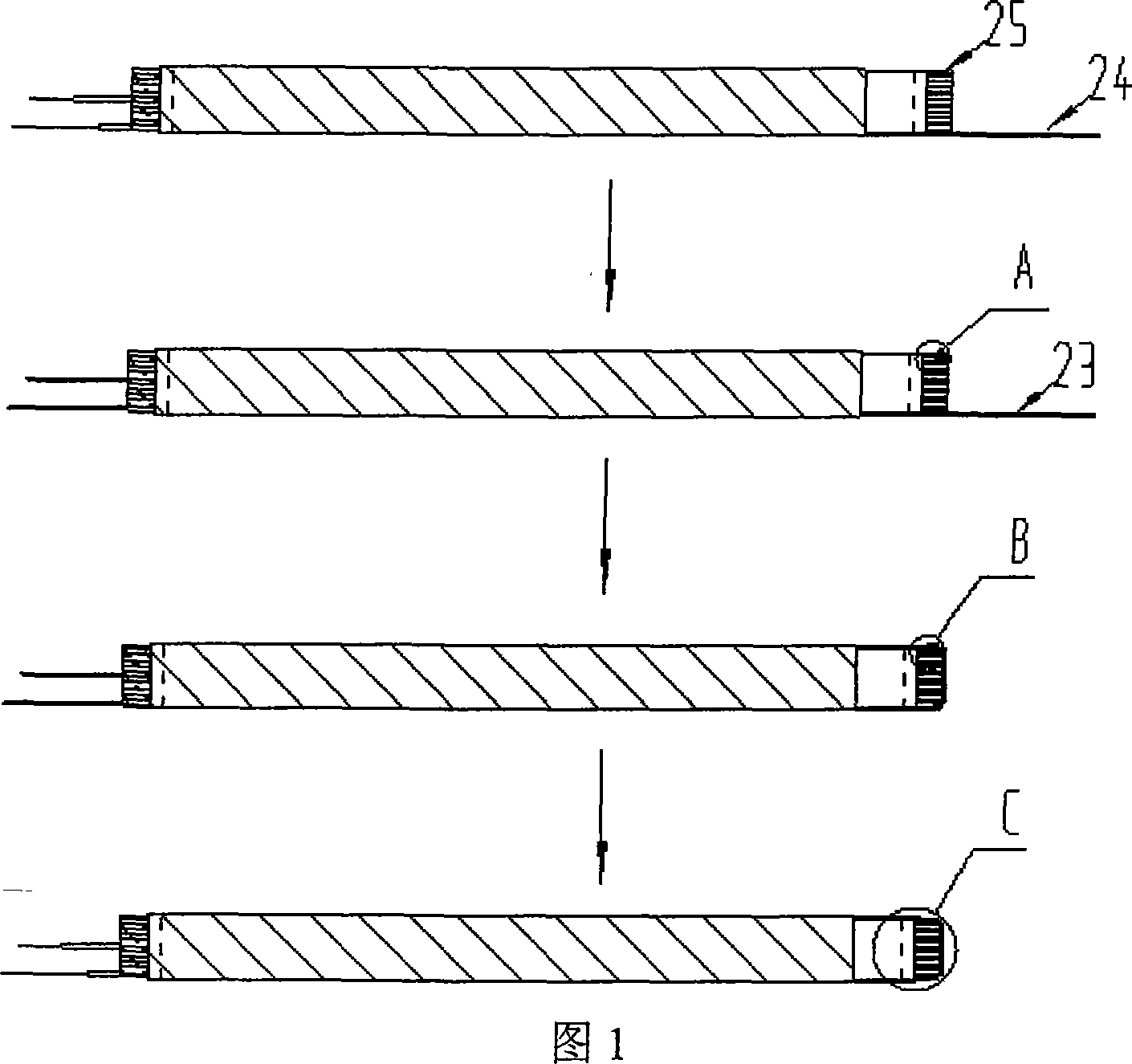

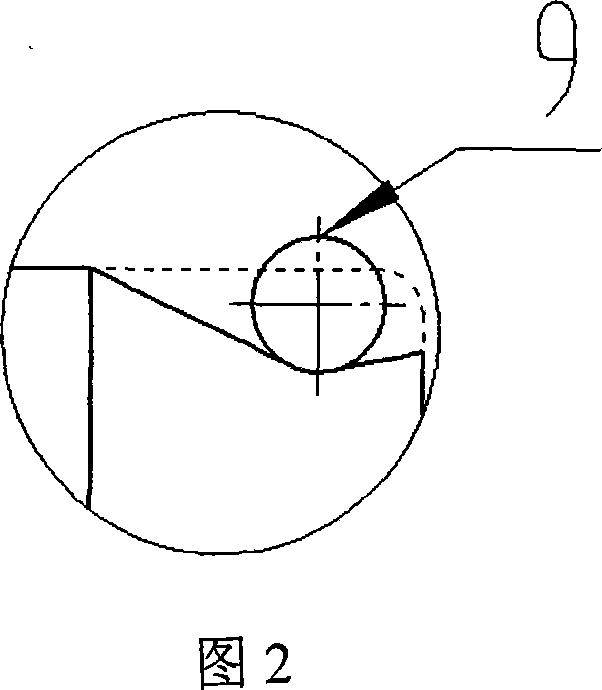

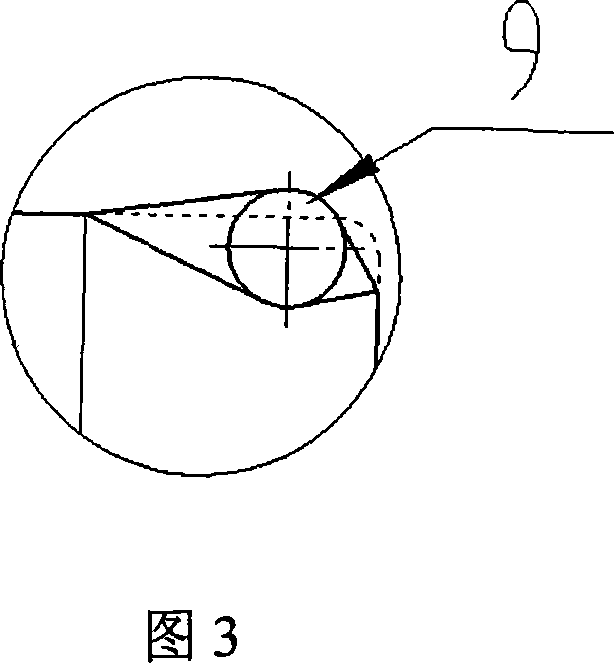

[0017] Below in conjunction with accompanying drawing 1~Fig. 4 and preferred embodiment, the concrete implementation step that the method of the present invention adopts is described in detail as follows:

[0018] (1) Paste protective tape on the lower surface of the bottom of the core as usual, and then set a diaphragm pinch with a diameter of 0.5mm to 1mm in parallel on the upper surface of the diaphragm at the bottom of the core. For example, a high-gloss stainless steel thin shaft can be used. It is determined according to the remaining length of the diaphragm at the bottom of different cores, so that the diaphragm on the side is squeezed and shrinks slightly inward; the length of the end shaft is 2 to 15mm longer than the width of the core;

[0019] (2) Flip the adhesive tape pasted on the lower surface of the bottom of the core upwards, and wrap it together with the diaphragm pinch; due to the protection of the diaphragm pinch, the bottom diaphragm and the bottom pole pie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com