Automatically compensating clamping sealing device of glasses valve

An automatic compensation, clamping and sealing technology, used in valve devices, sliding valves, engine components, etc., can solve problems such as poor sealing, high cost, leakage, etc., to avoid rigid compression, uniform load, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

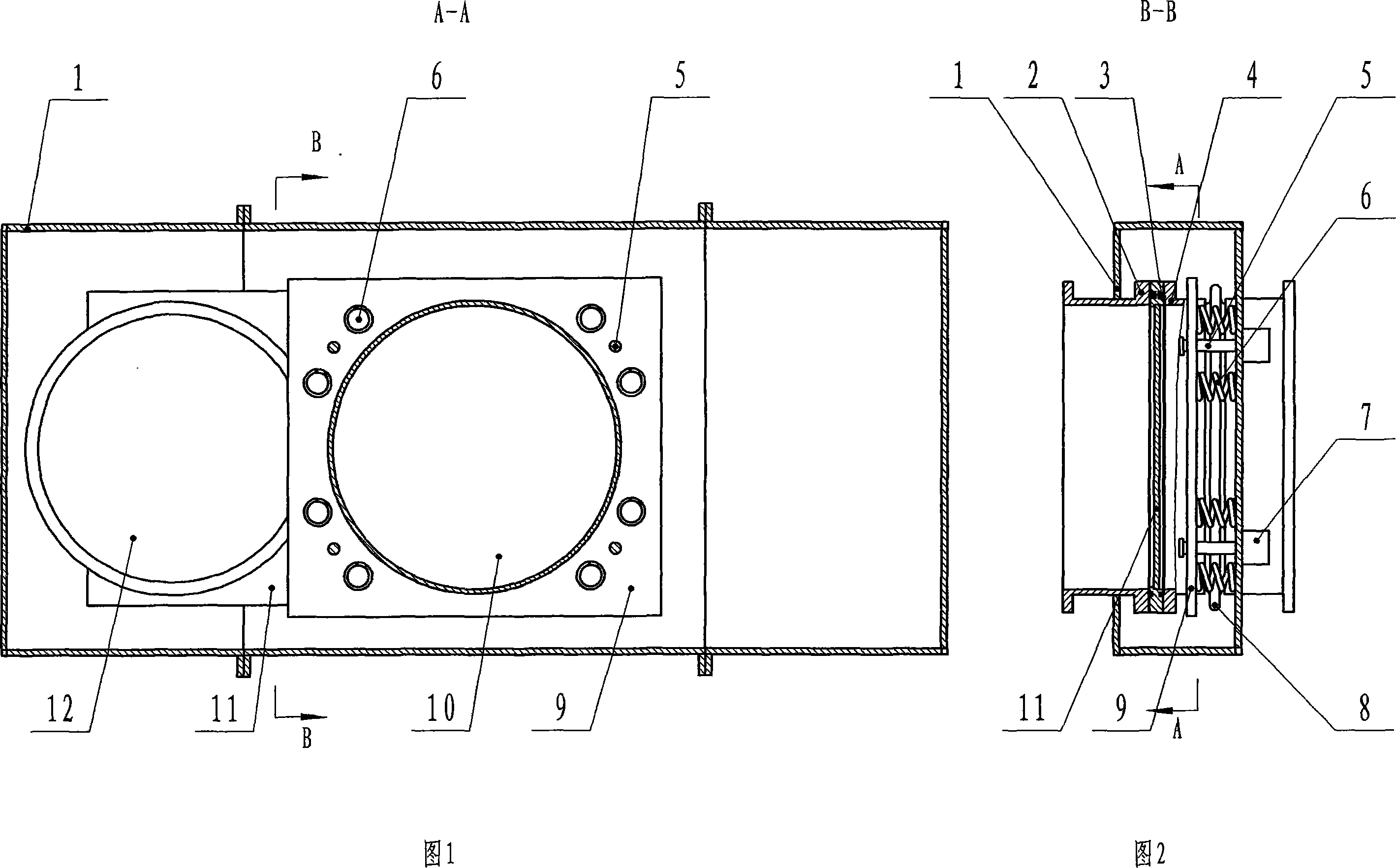

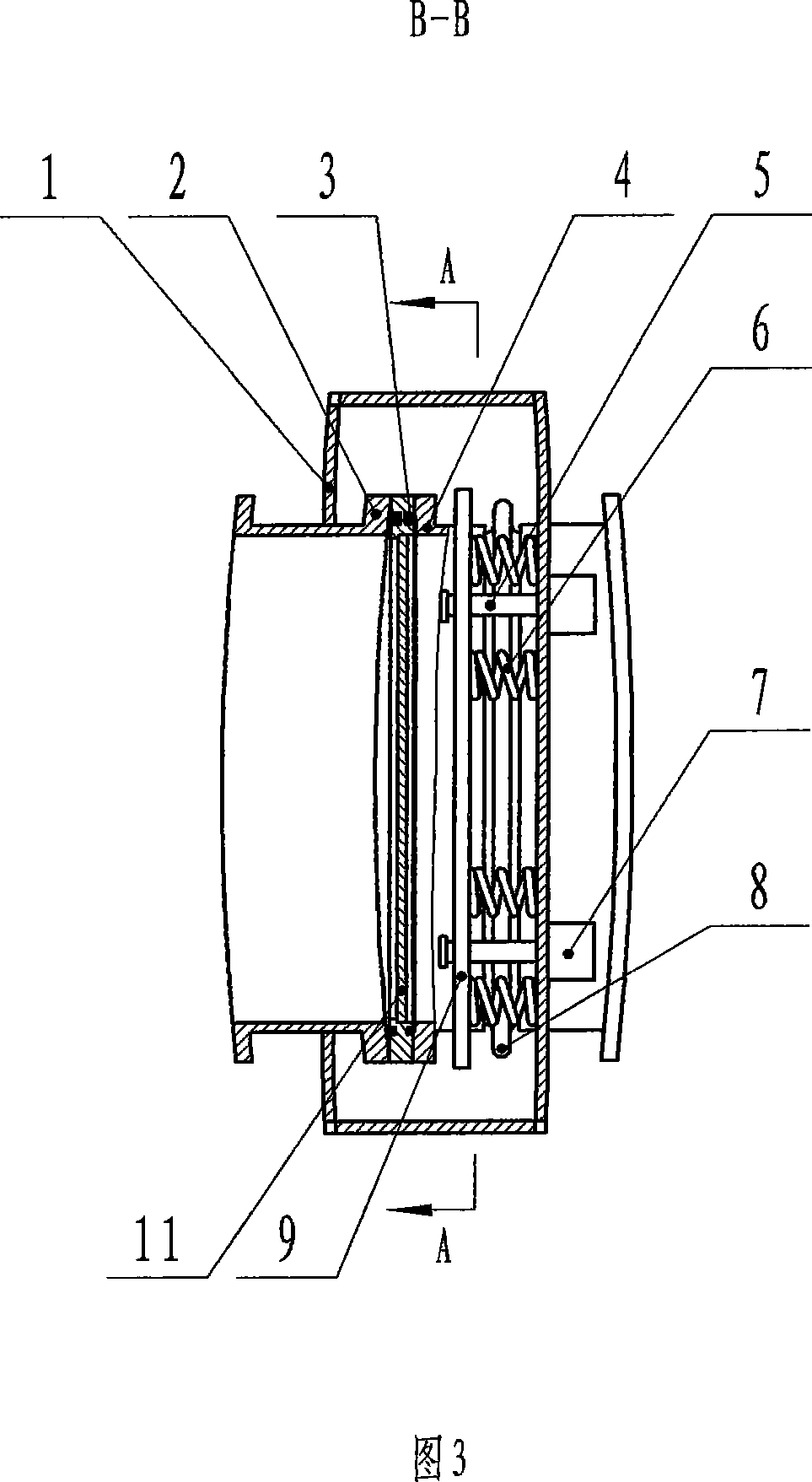

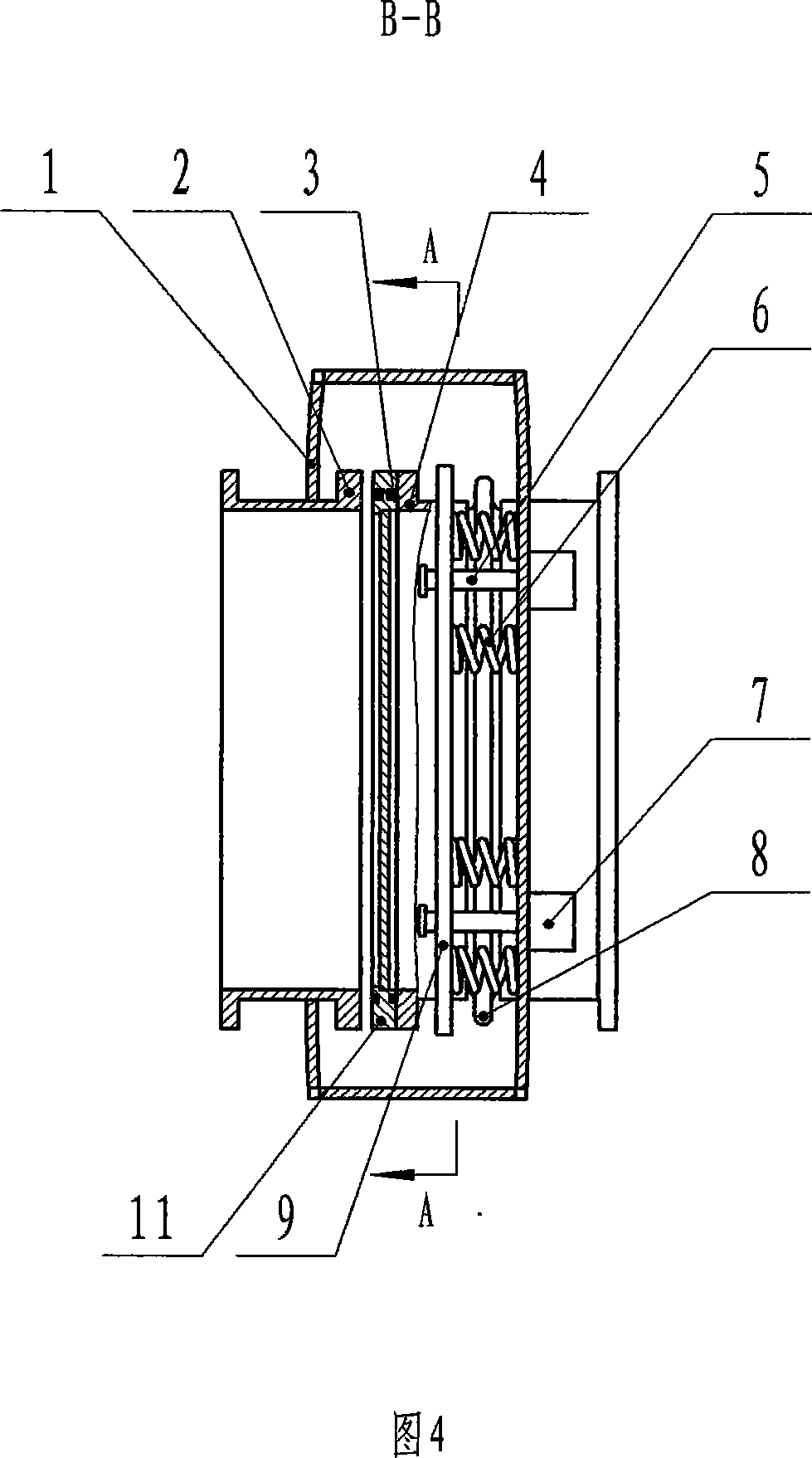

[0022] Embodiment 1 (for medium caliber glasses valve):

[0023] Embodiment 1 shown in Figures 1 and 2 is an automatic compensation clamping and sealing device used in glasses valves with medium caliber (pipe diameter φ1000-2400mm), which consists of a built-in automatic compensation clamping mechanism and a power mechanism that performs the function of pulling apart 7. Composed of pull rods 5; the built-in automatic compensation clamping mechanism is composed of clamping springs 6 biased on both sides of the longitudinal axis of the pipeline. The number of clamping springs 6 is 8, and the clamping springs 6 take the longitudinal axis of the pipeline as the symmetrical axis Symmetrical distribution; one end of the clamping spring 6 is in contact with the side wall of the movable valve seat pull plate 9, and the other end of the clamping spring 6 is in contact with the inner side wall of the valve body 1; the power mechanism 7 that performs the function of pulling apart is insta...

Embodiment 2

[0033] Embodiment 2 (for small-diameter glasses valve, the pipe diameter is φ600-700mm):

[0034] The difference between embodiment 2 and embodiment 1 is that the number of pull rods 5 is 2, and the number of clamping springs 6 is 2-4.

Embodiment 3

[0035] Embodiment 3 (for large-diameter glasses valve, the pipe diameter is φ2600-4000mm):

[0036] The difference between embodiment 3 and embodiment 1 is that the number of pull rods 5 is 8, and the number of clamping springs is 16-20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com