Hot pressure blowing method of forming metal bottle

A technology of metal bottle and blowing method, applied in the field of metal bottle hot pressing blowing method, can solve the problems of complex appearance updating process and single appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] 1. Process structure

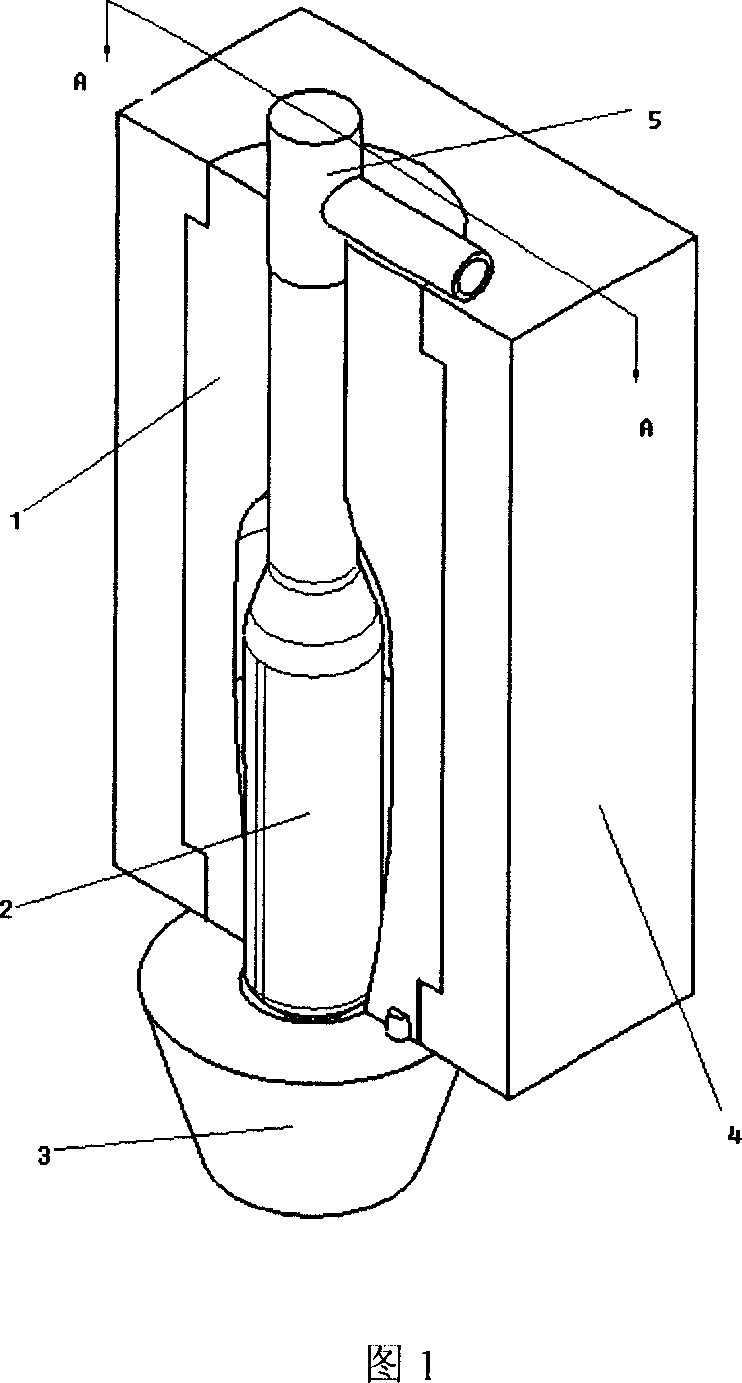

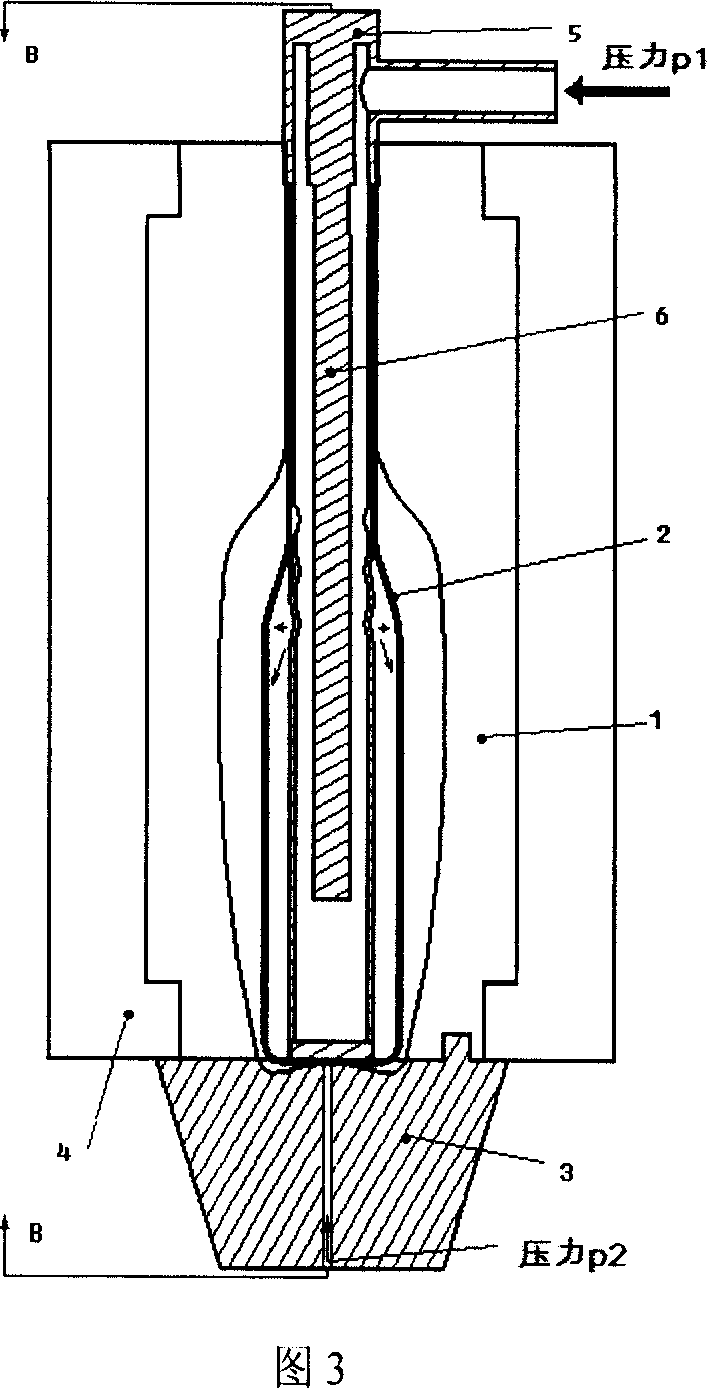

[0015] The process structure diagram of the metal bottle hot press blowing method is shown in Figure 1. It consists of a mold base, left and right side molds, a bottom mold, a pressure conduit and a heating device.

[0016] 1) preform

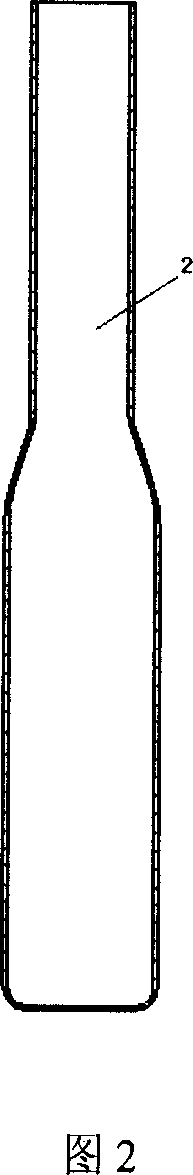

[0017] The preform is the blank before forming the metal container, which can be formed by the traditional stamping and drawing process. The length of the preform should be equal to or slightly longer than the length of the container, and its diameter is determined according to the final shape of the container. The preform is usually a necked preform (Figure 2).

[0018] 2) Side molds (left and right side molds) and bottom molds

[0019] Side and bottom molds are used to form a closed cavity whose shape determines the final shape of the metal container. Dividing the closed cavity into left and right side molds and a bottom mold is convenient for placing the preform and taking out the molded container. There ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com