Laser machining apparatus for main-bearing cracker of engine cylinder

A technology of engine cylinder block and main bearing seat, applied in metal processing equipment, laser welding equipment, welding equipment, etc., can solve the problems of affecting the processing accuracy of cracking tank, affecting the quality of cracking processing, increasing cracking force, etc., and achieving small deformation. , The effect of reducing the slag phenomenon and improving the machining accuracy

Inactive Publication Date: 2007-09-05

JILIN UNIV

View PDF2 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The tool wear of broaching the cracking groove is serious, and the tool wear will affect the machining accuracy of the cracking groove, and when the sharp angle of the broach becomes blunt, the cracking force will be increased, which will affect the cracking processing quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

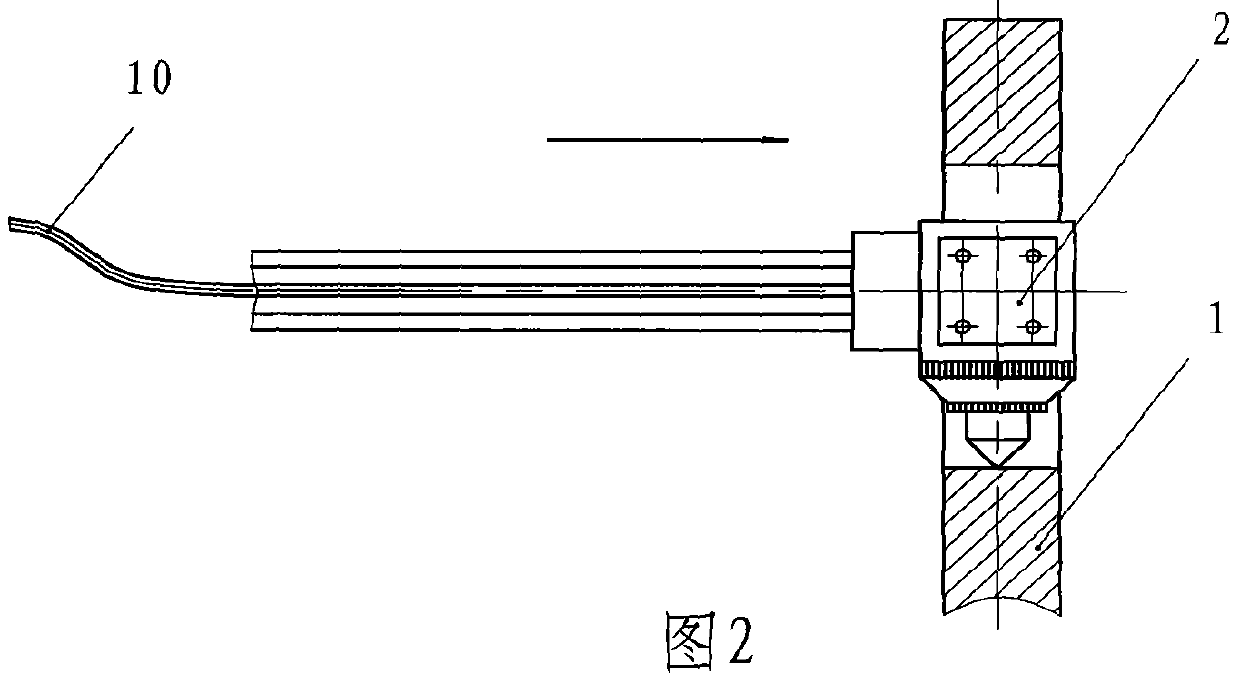

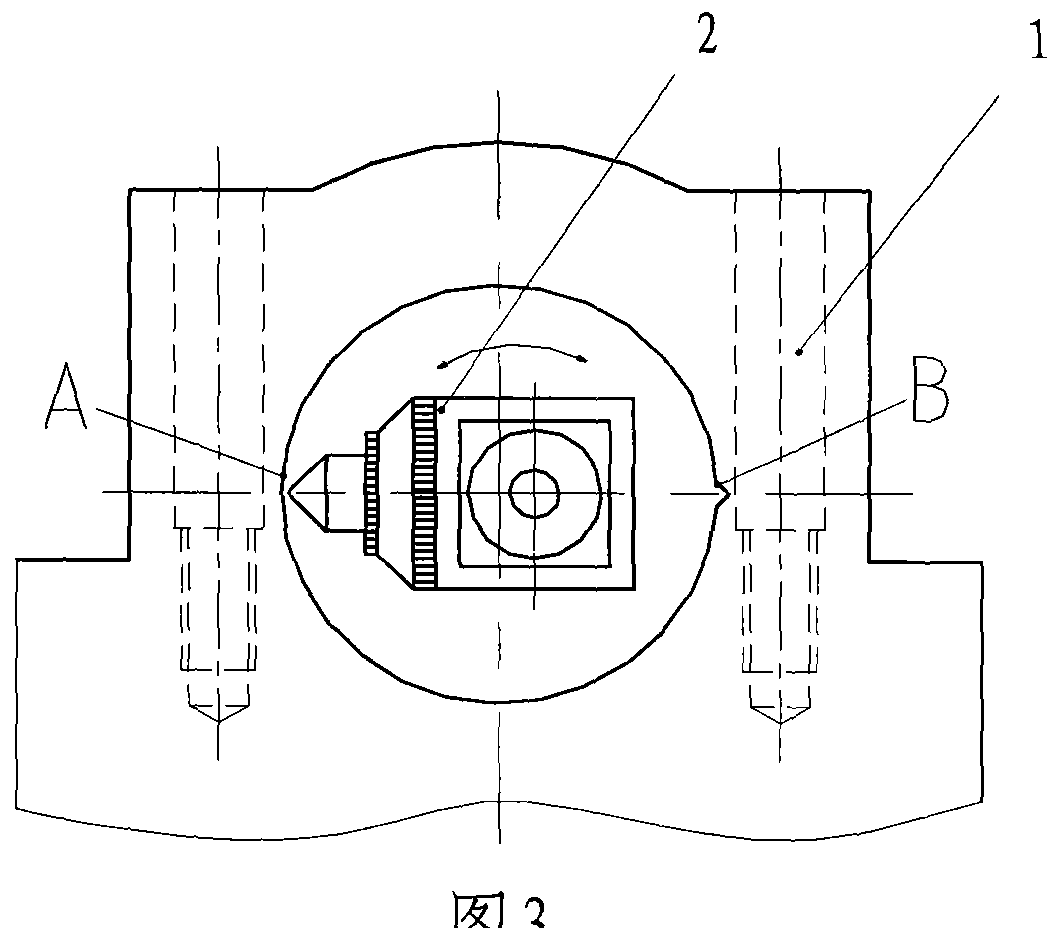

A laser machining apparatus for machining the splitting slot on master bearing seat for the cylinder body of engine is composed of a mechanical system and a YAG solid laser cutting system. Said mechanical system consists of cylinder body and its machine frame, and bench and its machine frame. Said bench comprises a numerally controlled X-Y bench, an X-axis bench and a Y-axis bench with a laser cutting head driven by a rotary cylinder to rotate by 180 deg.

Description

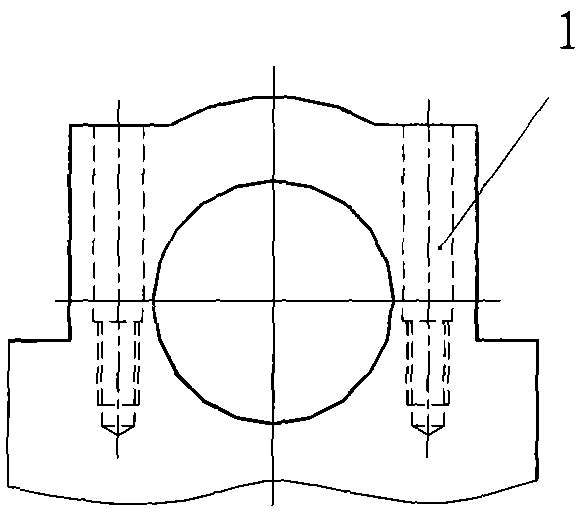

technical field The invention relates to special laser processing equipment for cracking grooves of main bearing seats of engine cylinder blocks. Background technique The traditional processing method of the main bearing seat of the engine cylinder block is separate processing, that is, the bearing cover and the bearing seat (the bearing seat and the cylinder block are integral castings) are cast separately, and then the joint surfaces are milled separately, and the bolts are processed separately. hole. The traditional process has low production efficiency, high manufacturing cost and poor assembly accuracy. The cracking processing technology of the main bearing seat of the engine cylinder is to first process the initial cracking grooves A and B on both sides of the center of the main bearing seat 1 hole of the integrally cast and semi-finishing cylinder block, and then use the cracking special equipment to process the bearing seat holes. The normal stress applied to the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K26/38B23K26/08B23K26/42B23K26/70

Inventor 杨慎华寇淑清何东野赵勇金文明张驰邓春萍郑祺峰

Owner JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com