Ball joint with a sealing bellow

A spherical universal joint and spherical pivot technology, applied in the directions of shafts and bearings, suspensions, pivots, etc., can solve the problems of increased cost, troublesome, damage to the sealing effect of the sealing box and the spherical pivot, etc., to achieve tightness beneficial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

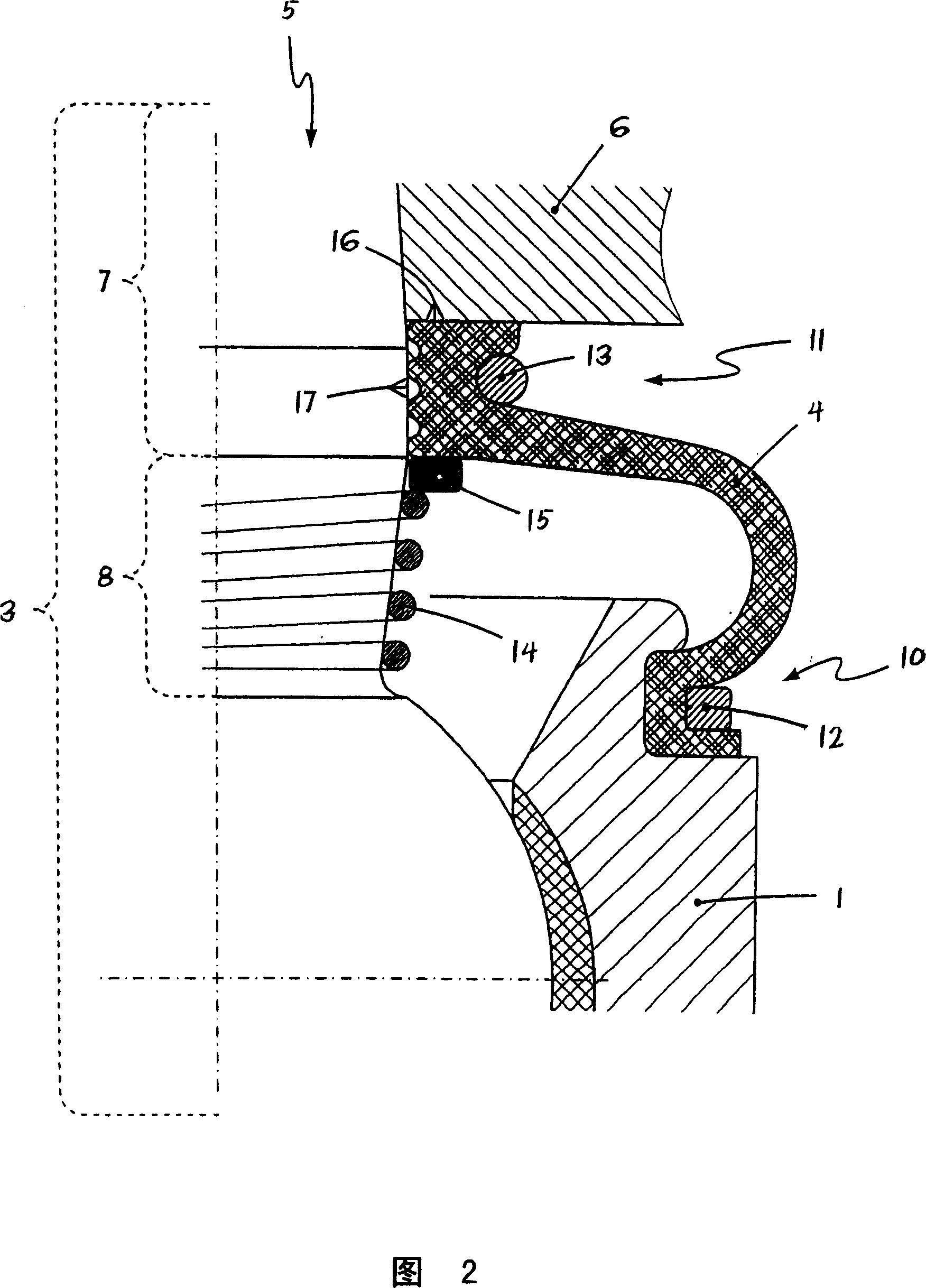

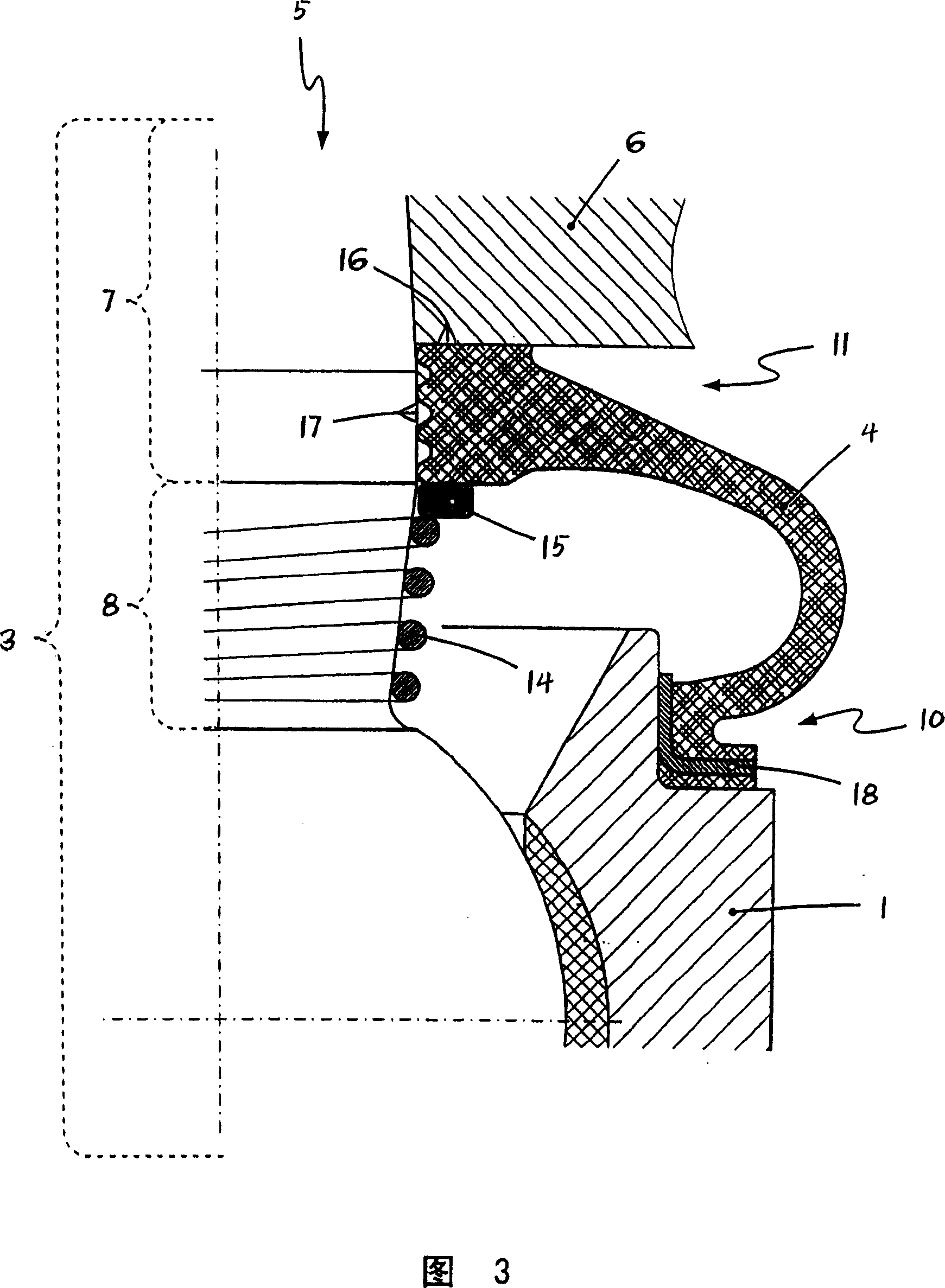

[0042] FIG. 1 shows a first embodiment of a ball joint according to the invention. First, the main components of the ball joint can be seen, namely the joint housing 1 with the bearing housing 2 arranged therein as well as the ball pivot 3 and the sealing box 4 . At the upper part of the spherical pivot 3 with reference to the drawing, this spherical pivot 3 is screwed, for example, with a lever ring 5 of a push rod 6 or the like. However, position 6 can also be a chassis component, such as a transverse guide rod, or an axial component, such as a swivel bearing, wheel carrier or the like. The spherical pivot 3 consists of a shank area 7 , a neck area 8 and a ball 9 .

[0043] It can also be seen that the sealing box 4 has two connecting straps 10 , 11 which form the connection of the sealing box 4 at the joint housing 1 or at the stem region 7 of the ball pivot 3 . In the exemplary embodiment shown, the two connecting straps 10, 11 each have a clamping ring 12, 13, which sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com