Curable liquid resin optical fiber upjacket composition

A technology of liquid resin and composition, used in optics, optical components, instruments, etc., can solve the problem of insufficient removability of tight cladding, achieve excellent strength and weather resistance, and improve usability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and comparative example 1-5

[0108] Each component of the composition shown in Table 1 was charged in a reactor equipped with a stirrer. The mixture was stirred at 50° C. for 1 hour to obtain a curable liquid resin composition.

[0109] testing method

[0110] The curable liquid resin compositions obtained in the above Examples and Comparative Examples were cured to prepare test samples. The following evaluations were performed on the test samples.

[0111] The curable liquid resin composition is coated on a glass plate with a coating device with a gap size of 250 μm, and the dose is 1J / em in air 2 Cured by ultraviolet light to obtain a Young's modulus measurement film. The film was cut into strip-shaped samples so that the portion to be stretched was 6 mm wide and 25 mm long. Tensile measurements were performed on the samples at a temperature of 23°C and a humidity of 50%. Young's modulus was calculated from the tensile strength at a stretch rate of 1 mm / min and a strain of 2.5%.

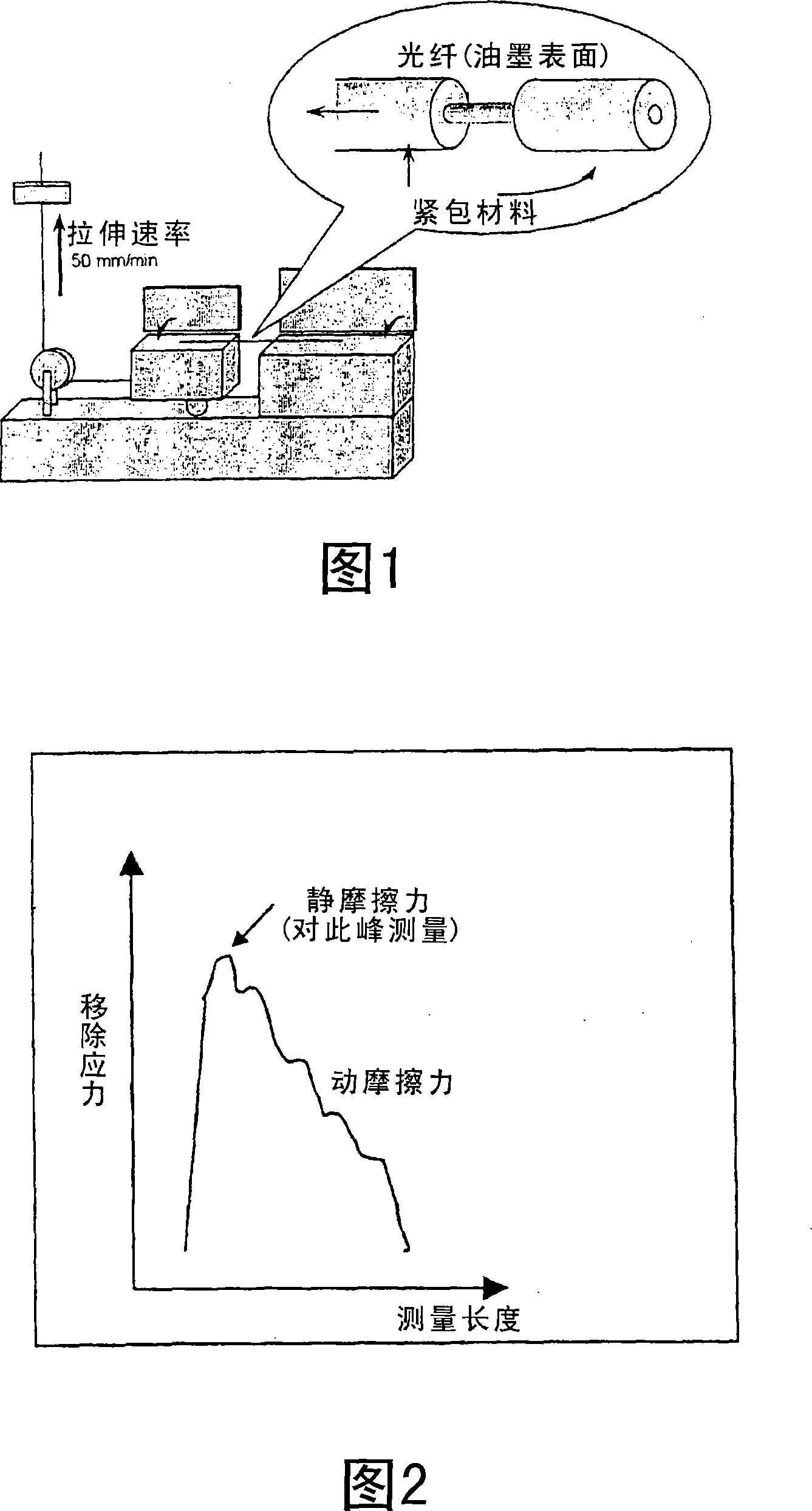

[0112] 2. Remo...

preparation Embodiment 6-8

[0119] B. Preparation Examples 6-8 (Table 2)

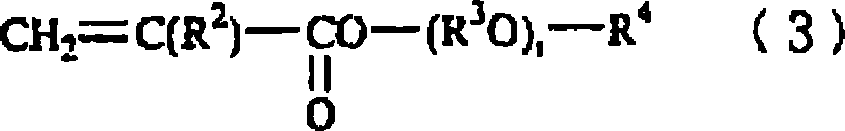

[0120] Urethane acrylate oligomer TH-PPG1000-TH was prepared by reacting toluene diisocyanate with 2-HEA. The reactants comprising isocyanates with reactive ends were then reacted with polyether polyol P1010 in the presence of dibutyltin dilaurate until unreacted levels were found to be below 0.1%.

Embodiment 6

[0121] The tight coating composition of Example 6 was prepared by mixing the urethane acrylate oligomer with the other ingredients listed in Example 6 and heating.

[0122] The tight coating compositions of Examples 7 and 8 were prepared by mixing and heating the ingredients listed in Examples 7 and 8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com