Vacuum drying apparatus

A vacuum drying device and vacuum pump technology, applied in the direction of drying solid materials, local agitation dryers, and static material dryers, etc., can solve the problems of reducing production costs and environmental protection, unable to recover organic solvents, and small vacuum pumping capacity. Achieve the effect of reducing environmental protection, increasing the contact area, and reducing the pressure quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

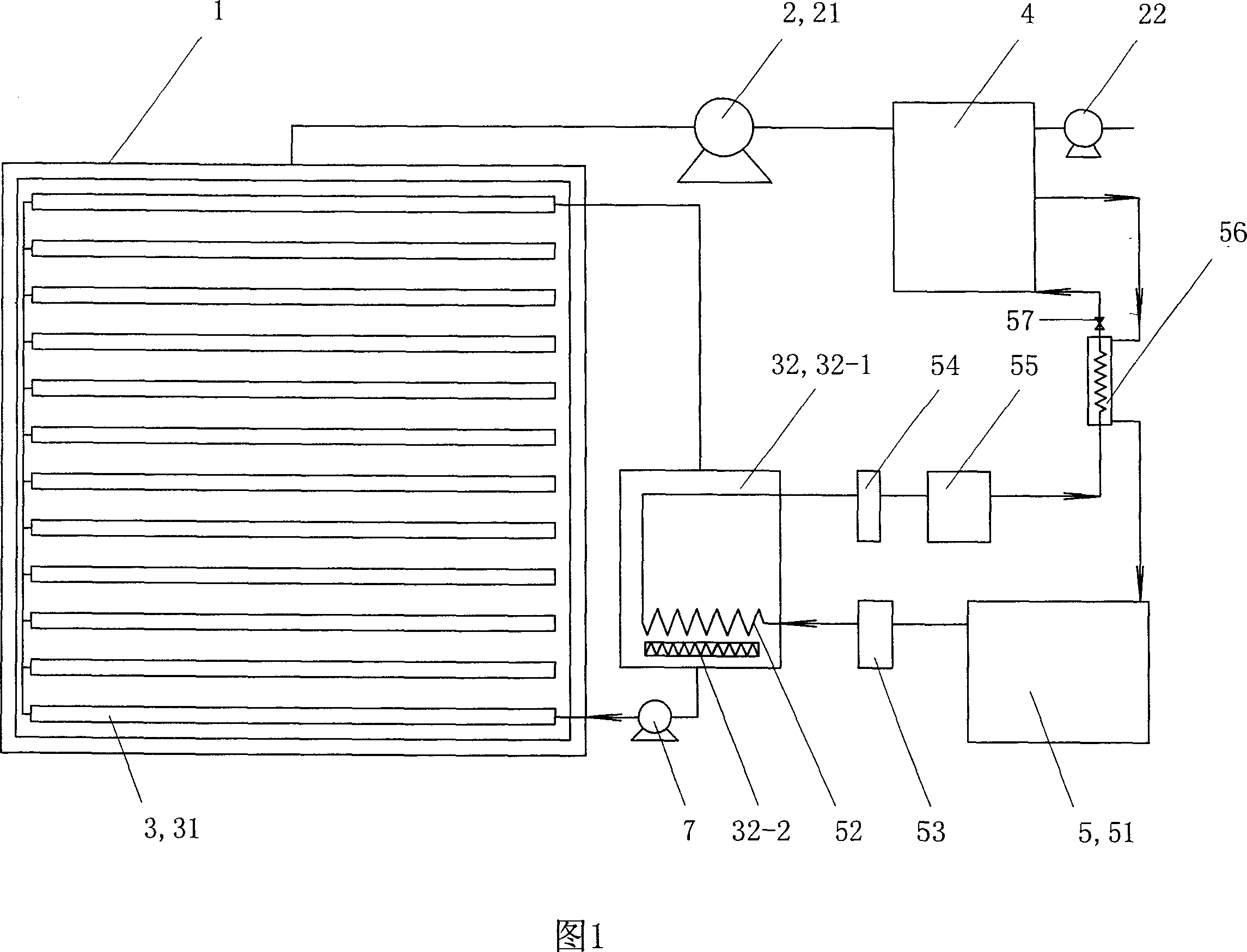

[0021] See Fig. 1, the vacuum drying device of the present invention has casing 1, vacuum pump 2 and heating assembly 3, and heating assembly 3 has the hot plate 31 that is arranged in casing 1 and is arranged on the outside of casing and provides heat energy for hot plate 31. Heater or heat exchanger 32; vacuum pump 2 is made up of Roots pump 21 and rotary vane pump 22, and condensation catcher 4 is connected in series between Roots pump 21 and rotary vane pump 22, and described condensation catcher 4 and compressor 51 , expansion valve 57, and heat exchanger 52 form the cooling cycle system 5.

[0022] The electric heater 32 has a heat conduction oil tank 32-1, an electric heating tube or a heat exchanger 32-2 is arranged in the heat conduction oil tank, a thermal oil pump 7 is arranged outside the heat conduction oil tank 32-1, and a channel is provided inside the heat plate 31, and the channel The inlet is connected to the thermal oil pump 7, and the outlet of the channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com