Scavenger fan

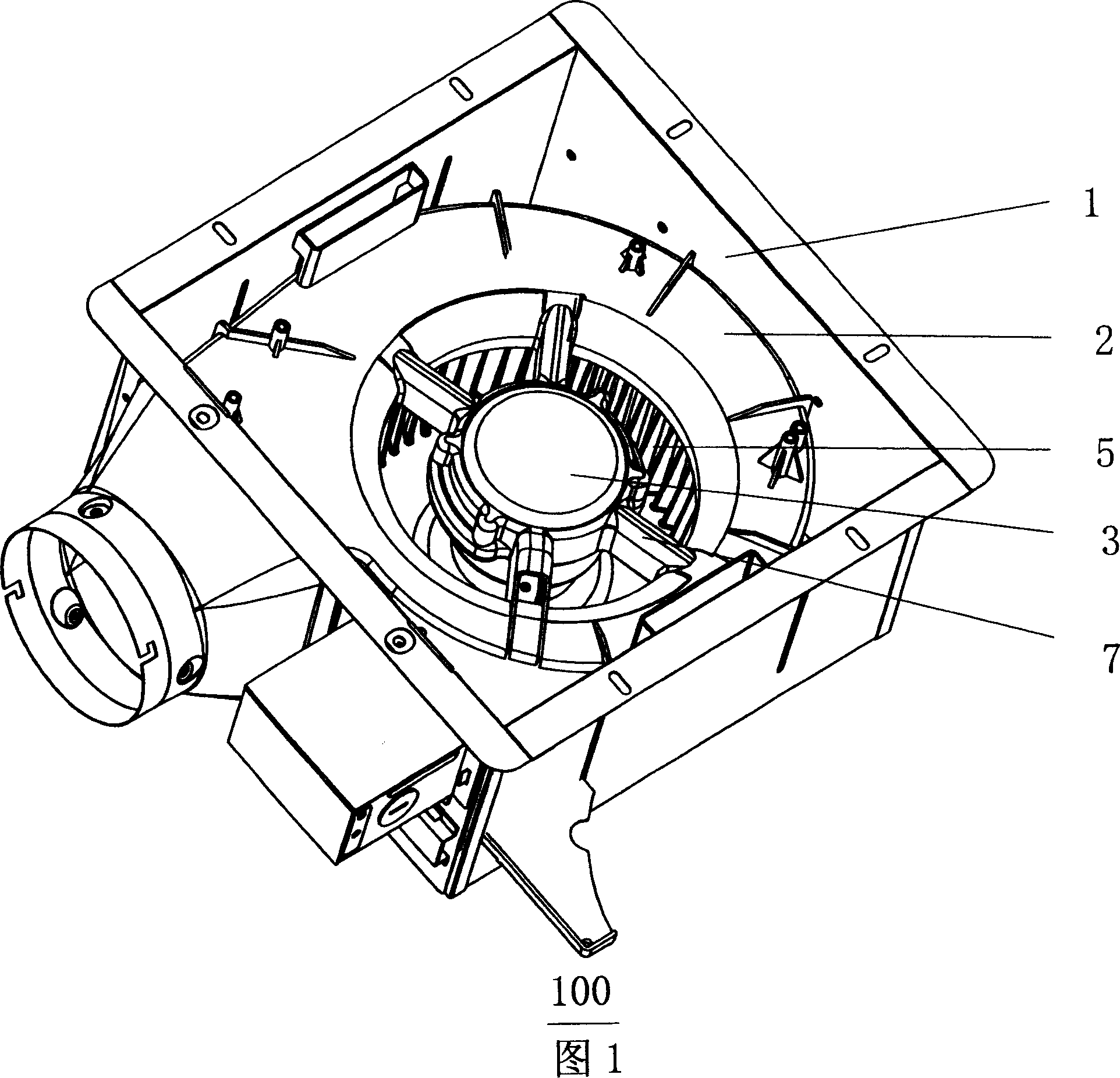

A technology for a ventilating fan and a metal bracket, which is applied in the field of ventilating fans, can solve the problems of deformation of the motor bracket, difficult heat dissipation structure, contact of fan blades 5, etc., and achieves the effect of improving heat dissipation and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

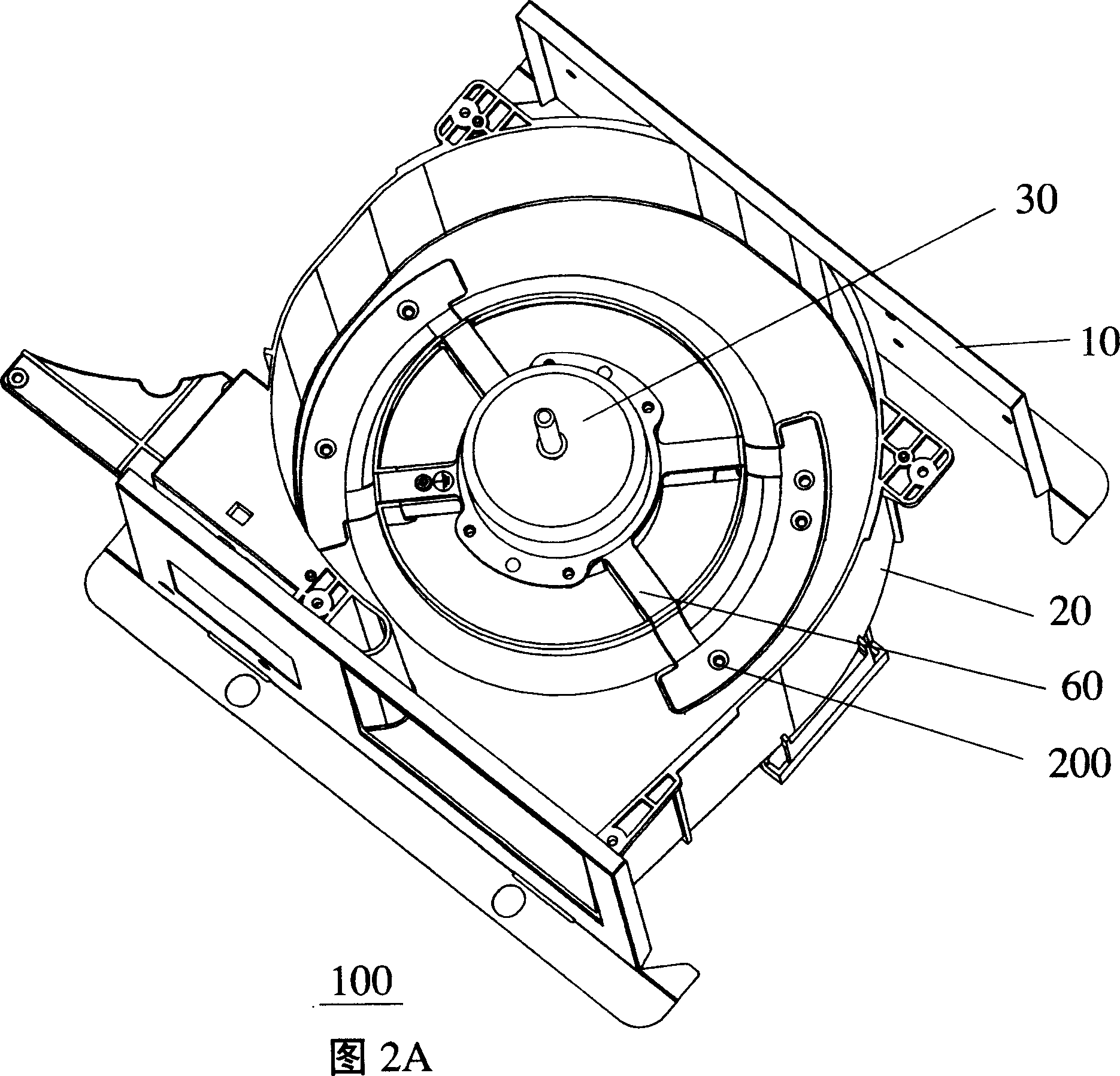

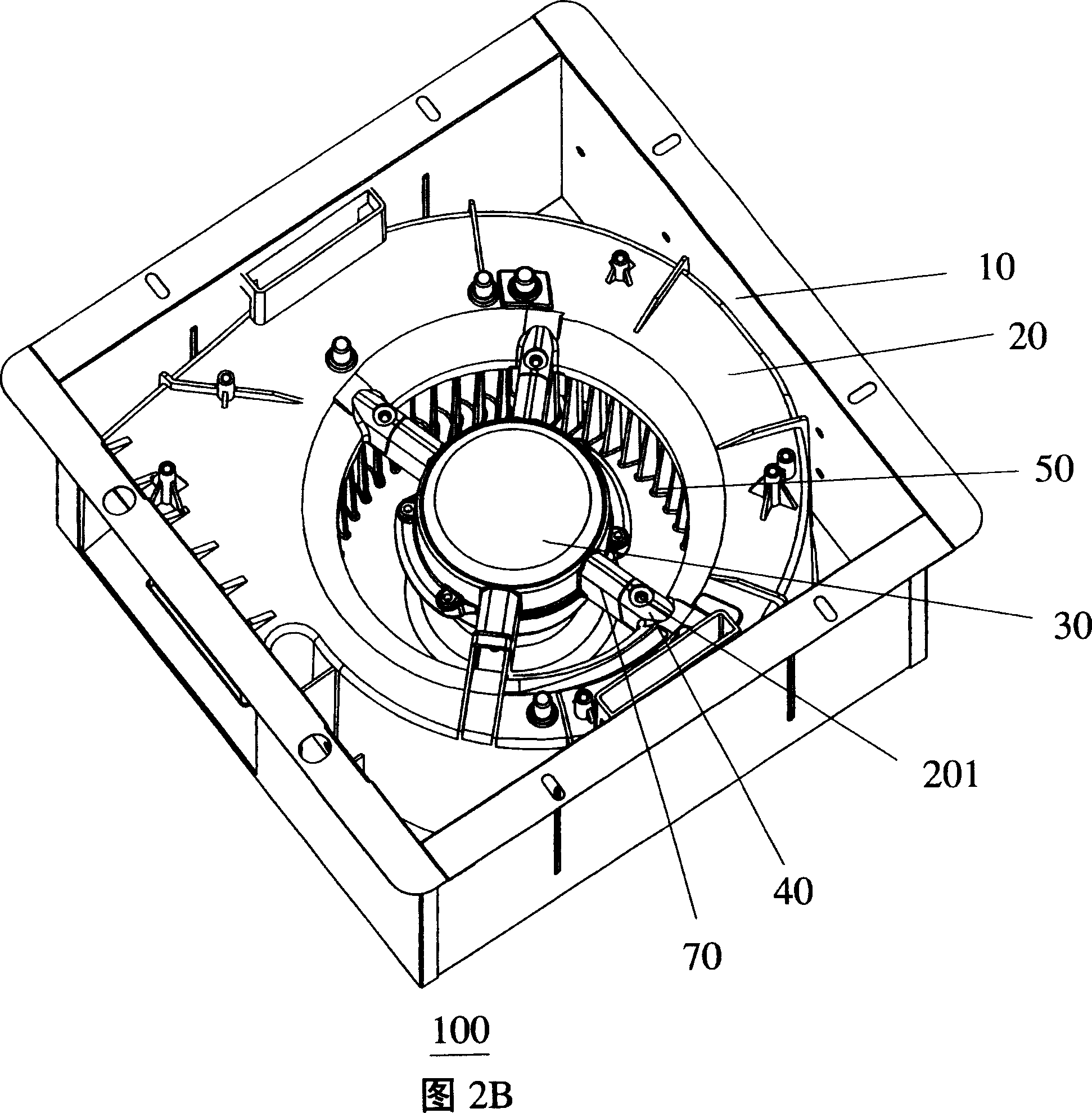

[0018] As shown in FIG. 2A and FIG. 2B , they are schematic diagrams of the front and back sides of the first embodiment of the present invention. For clarity of illustration, fan blades are removed in Fig. 2A. Ventilation fan 100 has frame 10 , snail shell 20 and motor 30 . The motor 30 is fixed on the opening in the snail shell 20 through a metal motor bracket, and the fan blade 50 is mounted on the motor 30 . It can be seen from the figure that the metal motor bracket is formed by superimposing and fixing the first metal bracket 60 and the second metal bracket 70 up and down. Compared with the known technology in FIG. 1 , the present invention changes the material of the motor bracket from resin to metal. The first metal bracket 60 and the second metal bracket 70 clamp and fix the motor together. One end of the first metal bracket 60 is fixed on the casing of the motor 30 , and the other end is finally connected into a sheet and fixed on the inner wall of the snail shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com