Axial flow positive displacement gas generator with combustion extending into an expansion section

A variable-capacity, axial-flow technology, used in combustion chambers, combustion equipment, combustion methods, etc., can solve the problem of not being able to have both at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

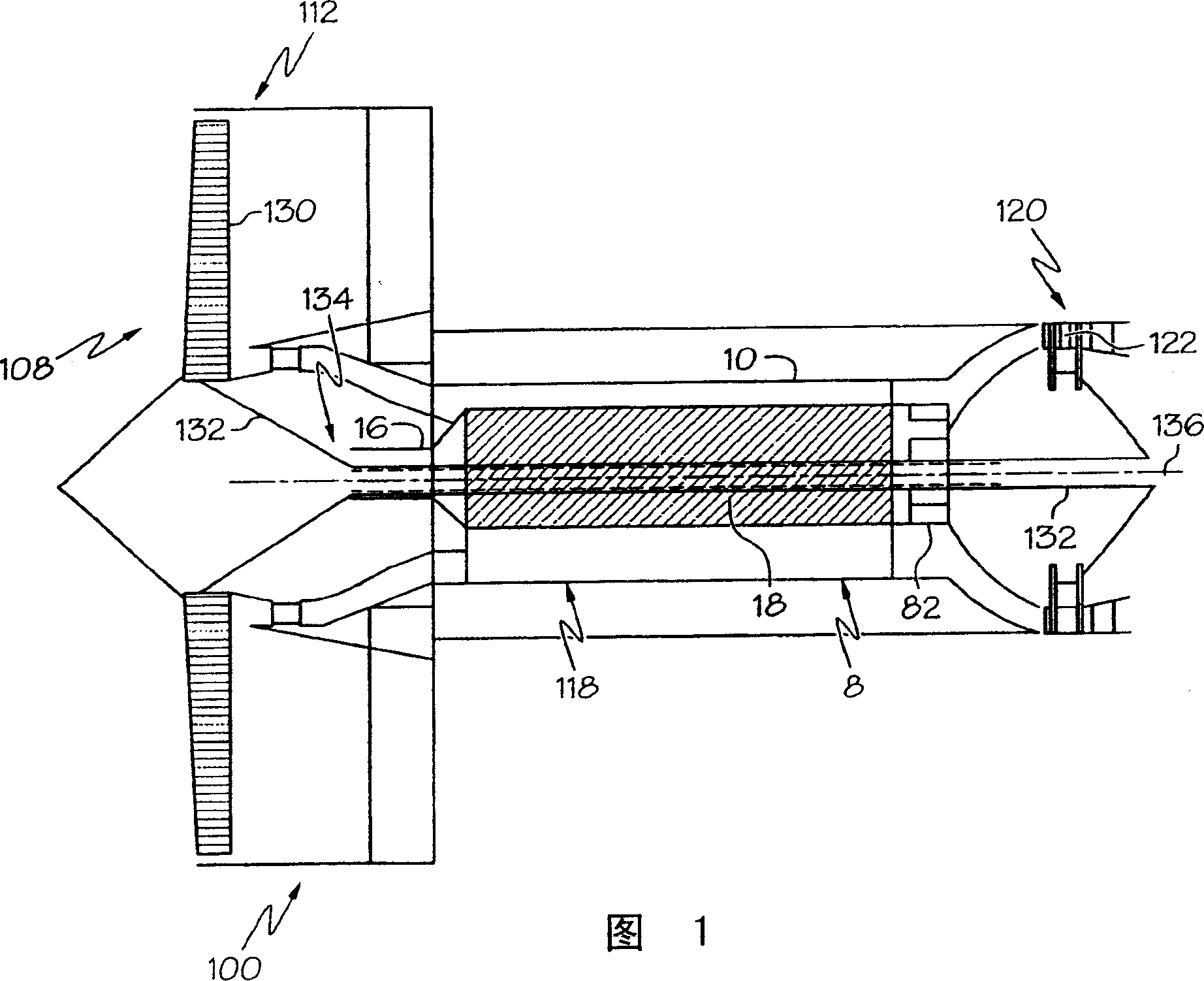

[0014] What Fig. 1 shows is an exemplary embodiment of variable displacement axial-flow engine 8, what shows here is a gas generator 10 in gas turbine engine 100 equipment, in this engine, gas generator 10 is used for The turbine is driven to do work to turn the fan 108 in the fan section of the engine 100 . The gas generator 10 can also be used to directly drive energy consumers, such as ship propulsion and generators or aircraft nozzles or fans. The exemplary embodiment of gas turbine engine 100 shown in FIG. 1 is an aircraft gas turbine engine having a core engine 118 with gas generator 10 downstream of fan section 112 . Gas is discharged from the gas generator 10 into a low pressure turbine (LPT) 120 having a row of low pressure turbine rotor blades 122 . The low pressure turbine rotor blades 122 drive a row of circumferentially spaced fan rotor blades 130 of the fan 108 connected to the fan section 112 via a low pressure shaft 132 to form a low pressure duct 134 around a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com