Single screen color line powder distributing device and method

A technology of line powder and distribution device, which is applied to supply devices, manufacturing tools, etc., can solve the problems of low efficiency, high cost, complex structure, etc., and achieve the effects of preventing waste, high distribution efficiency, and compact device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

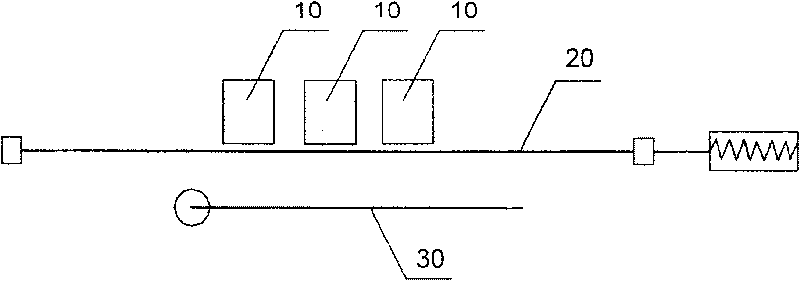

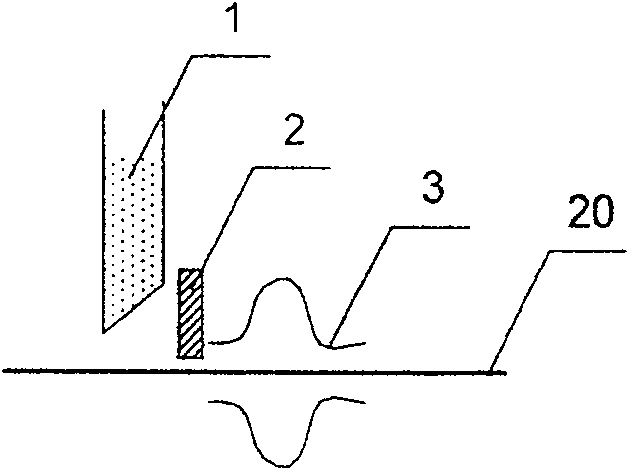

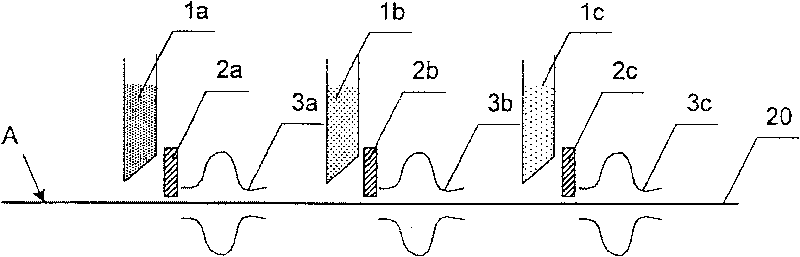

[0034] Figure 4a ~ Figure 4cIt is a work flow chart of the first embodiment of the present invention. The feeder, scraper and powder suction device in this embodiment are connected as a whole to form a combined distributor. The combined distributor is connected with a drive mechanism that drives it to move from one end of the screen to the other end, and the drive mechanism can be connected on a support. The screen in this embodiment is a flat screen mounted on a screen support, and the feeders of the three sequentially arranged combined distributors are each loaded with powder of one color.

[0035] Such as Figure 4a ~ Figure 4c As shown, the working process of this embodiment is: when the powder bearing carrier 30 moves below the screen 20, it stops moving, and the screen and the powder bearing carrier are in a static state. The three combined distributors move from right to left above the screen in turn, distributing the three colors of powder onto the powder carrier. ...

no. 2 example

[0042] Figure 5a ~ Figure 5c It is a work flow chart of the second embodiment of the present invention. The structure of the feeder, scraper and powder suction device in the combined distributor of this embodiment is basically the same as that of the first embodiment. The difference with the structure of the first embodiment is that the combined distributor of this embodiment is fixed, and the screen 20 It runs synchronously with the powder carrier 30. The feeder, scraper and powder suction device that make up each combined distributor can be respectively fixed on a bracket, and can also be connected as a whole. Specifically, the screen 20 of the present embodiment is an endless screen belt, which is sleeved on the screen transmission frame 21. The screen transmission frame 21 is used to support the screen 20 and allow the screen 20 to be connected to the powder bearing carrier 30 below it. Synchronous movement, for example, when the powder bearing carrier 30 moves from rig...

no. 3 example

[0050] On the basis of the technical solutions of the first and second embodiments, the screen of this embodiment is a flat wire screen erected on a wire screen support, and runs synchronously with the powder carrier, and the combined distributor is fixed to realize sequential distribution. , the specific process is the same as before, and will not be repeated here. When the powder material is distributed, the wire mesh makes a return movement, and completes the new cloth work together with the next powder carrier that enters the cloth station.

[0051] Figure 6 and Figure 7 The renderings after layout for various color powder materials. Such as Figure 6 As shown, the blue powder B first falls on the area powder on the powder bearing carrier below through the mesh, and then the yellow powder Y and red powder H, forming a multi-color superposition. Since the powder in the original area on the powder carrier before laying the line powder is in the shape of a pile with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com