Technological process and apparatus for fast shaping instant rice noodle cake

A process method and rice noodle technology, which are applied in the field of process methods and sizing equipment to facilitate the rapid setting of rice noodles, can solve the problems of limited hot water temperature requirements, high energy consumption, and rice noodles are too brittle, and achieve a wide range of hot water temperature requirements. , The effect of saving drying energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

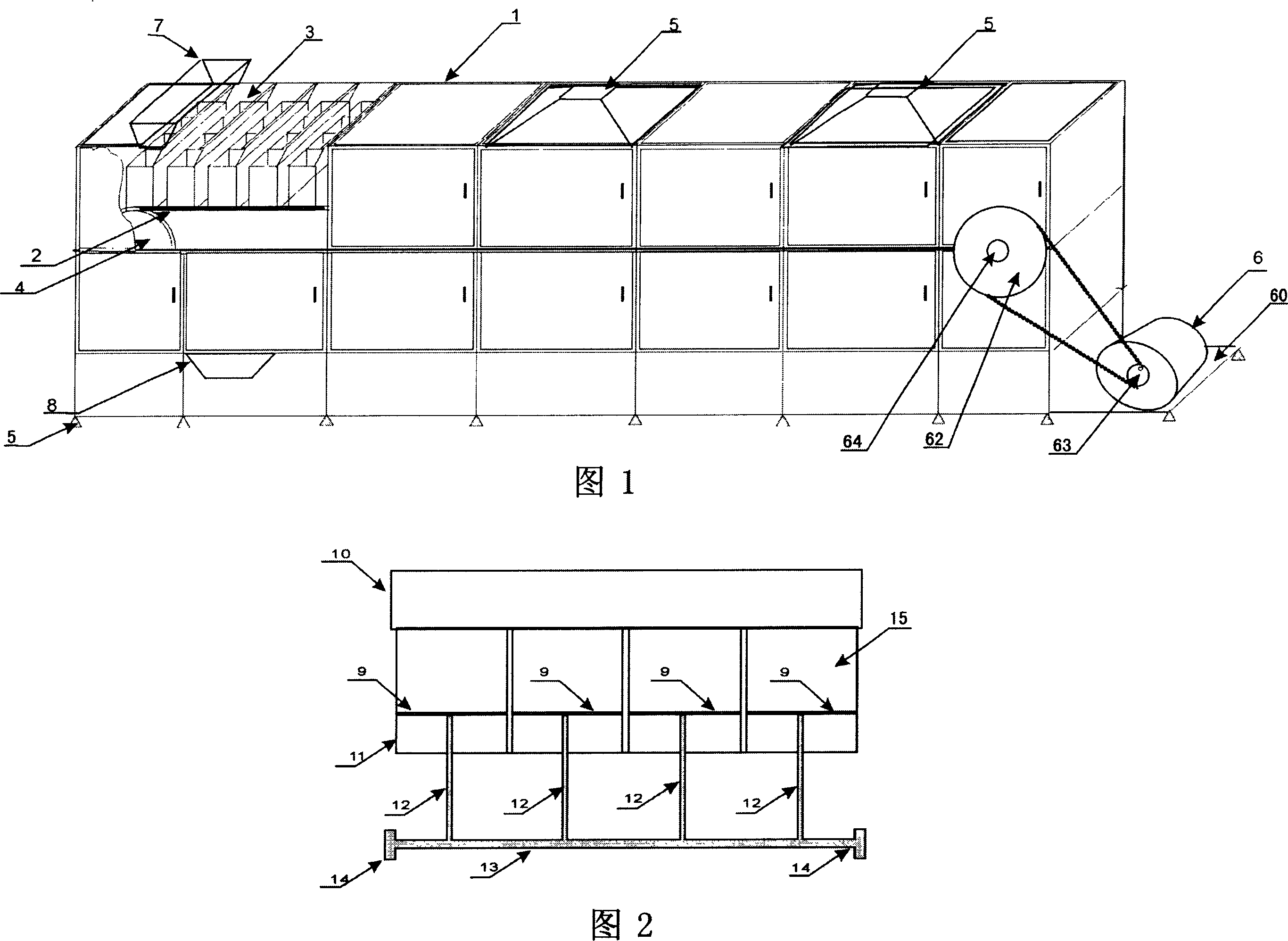

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] The process of the present invention is as follows: first aging the instant rice noodles, rubbing them loose, and measuring them, and placing the measured instant rice noodles on the conveyor belt (not shown) and automatically dropping them into the forming box 3 of the shaping device (within three minutes) finish), when the instant rice noodle enters the forming box 3, the lid 10 of the forming box 3 is also closed thereupon, so that the instant rice noodle is in the fully enclosed forming box 3, and the forming box 3 is always in a high-temperature environment, so that The instant rice noodles in the closed state are heated quickly, and the moisture inside the instant rice noodles evaporates to produce steam to make the instant rice noodles stew, ripen, and soften; After the water evaporates, it hardens and solidifies into in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com