Automatic fast royail jelly-jelly insect separating machine

A separator and pulpworm technology, applied in food science, honey harvesting, beekeeping, etc., can solve the problems of royal jelly and pulpworm equipment that have not been seen yet, and achieve the effect of saving labor and preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

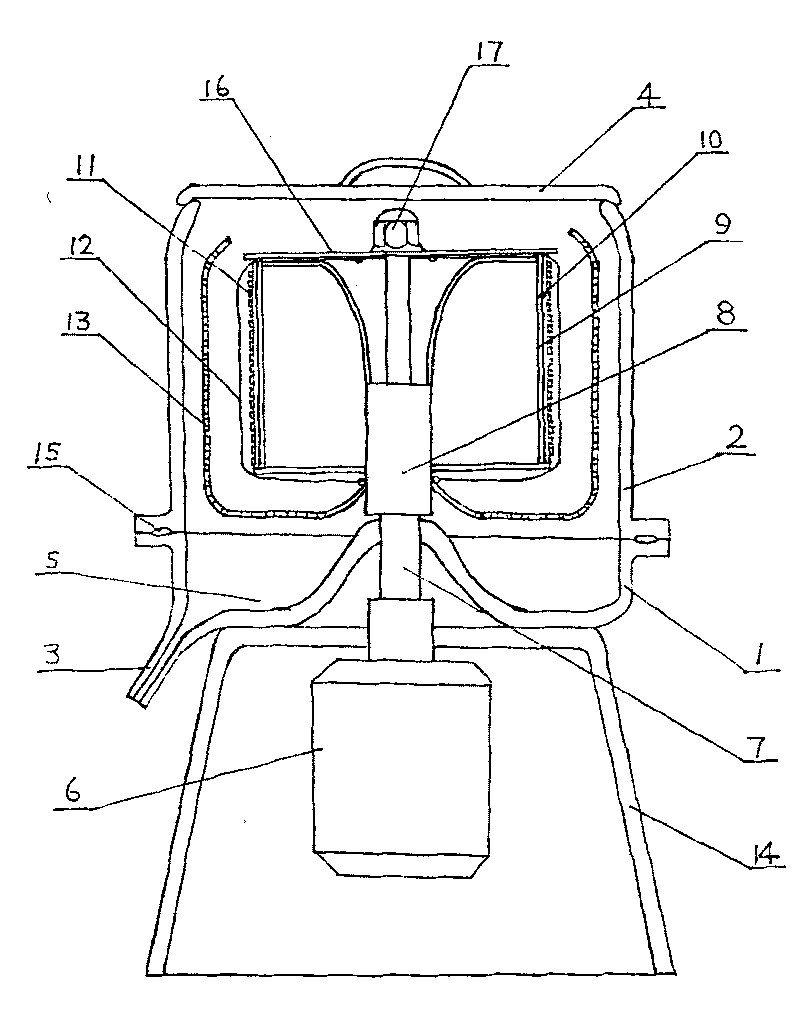

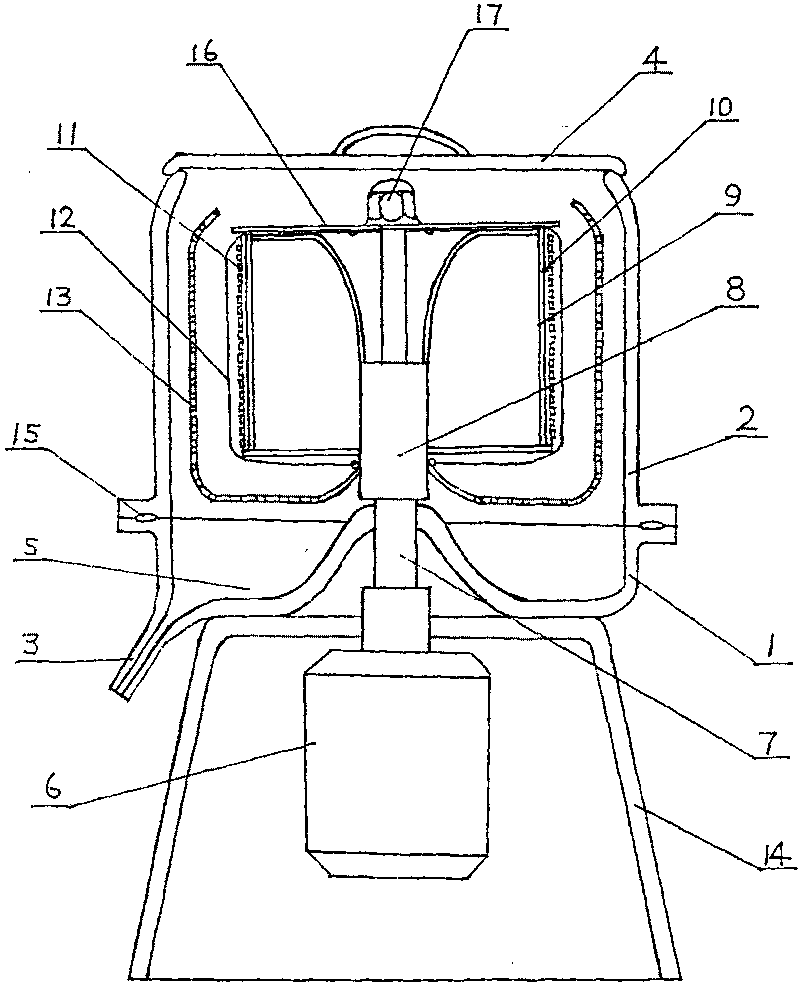

[0011] See figure 1 , There is a chassis 1, the upper end of the chassis 1 is connected with the main body 2, and the connection between the chassis 1 and the main body 2 is the convex edge of the non-toxic rubber ring gasket 15 in the center, and 3 uniformly distributed bolts are used between the convex parts Fixed; the upper end of the main body 2 is provided with an upper cover 4; the middle of the chassis 1 is a slurry plate 5, the center of the slurry plate 5 is a cone-shaped protrusion, and the center of the cone-shaped protrusion is provided with a main shaft 7 and a sealed bearing, and a slurry plate 5 The chassis 1 side of the chassis 1 is provided with a flow path 3 leading to the outside; the chassis 1 is fixed on the base 14 at its lower end, and the base 14 is provided with a DC motor 6; the spindle 7 controlled by the motor 6 has a speed of 300 per minute There are two kinds of ~800 and 1500~3000 revolutions; the main shaft 7 is connected with a shaft sleeve 8 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com