Coil tube for forming an inductive element

一种感应元件、线圈管的技术,应用在线圈、线圈制造、电气元件等方向,能够解决限制铜占空比、降低电气和、或磁特征等问题,达到简化制造过程、降低损耗、易于拆卸和处理的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

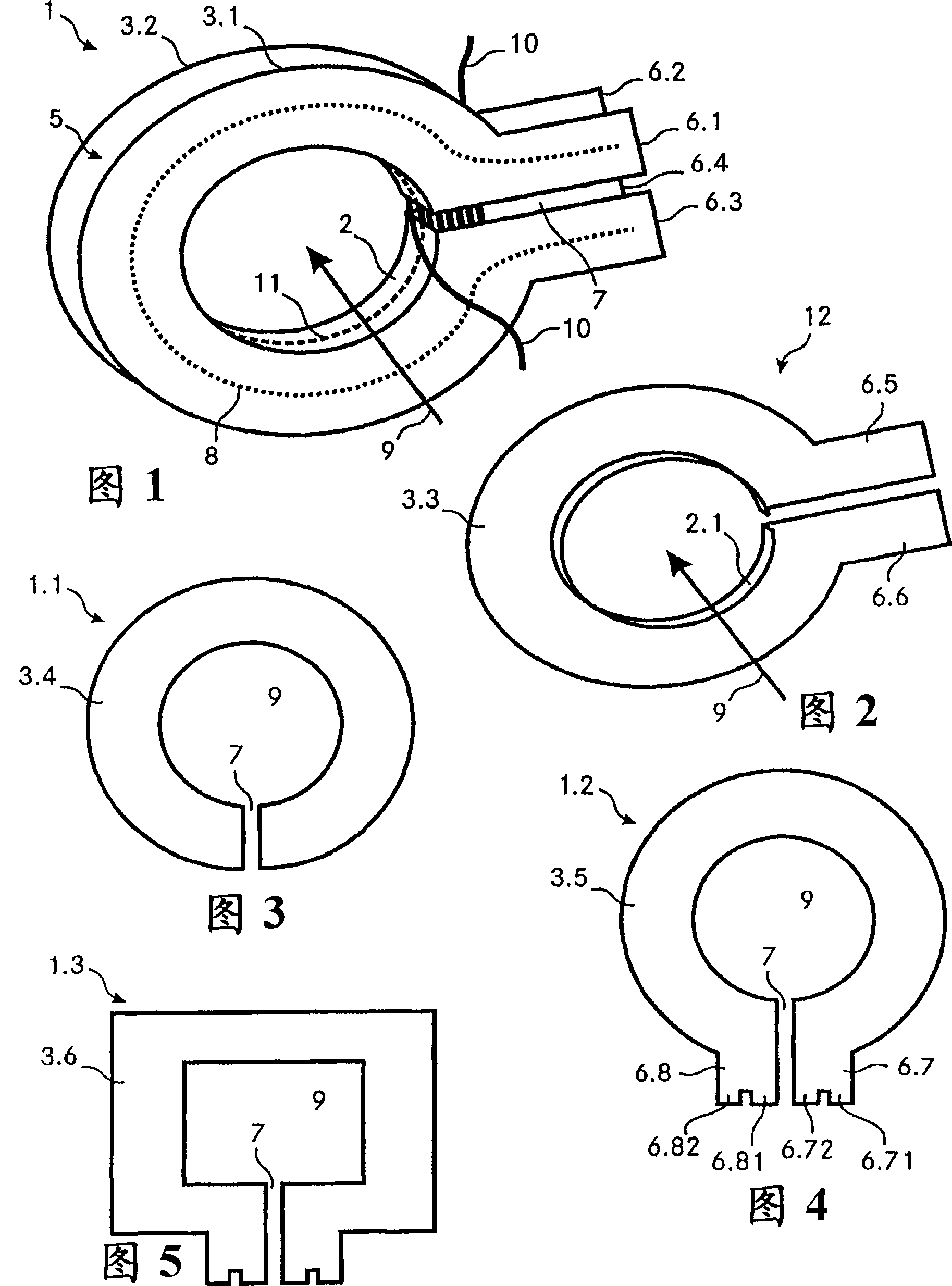

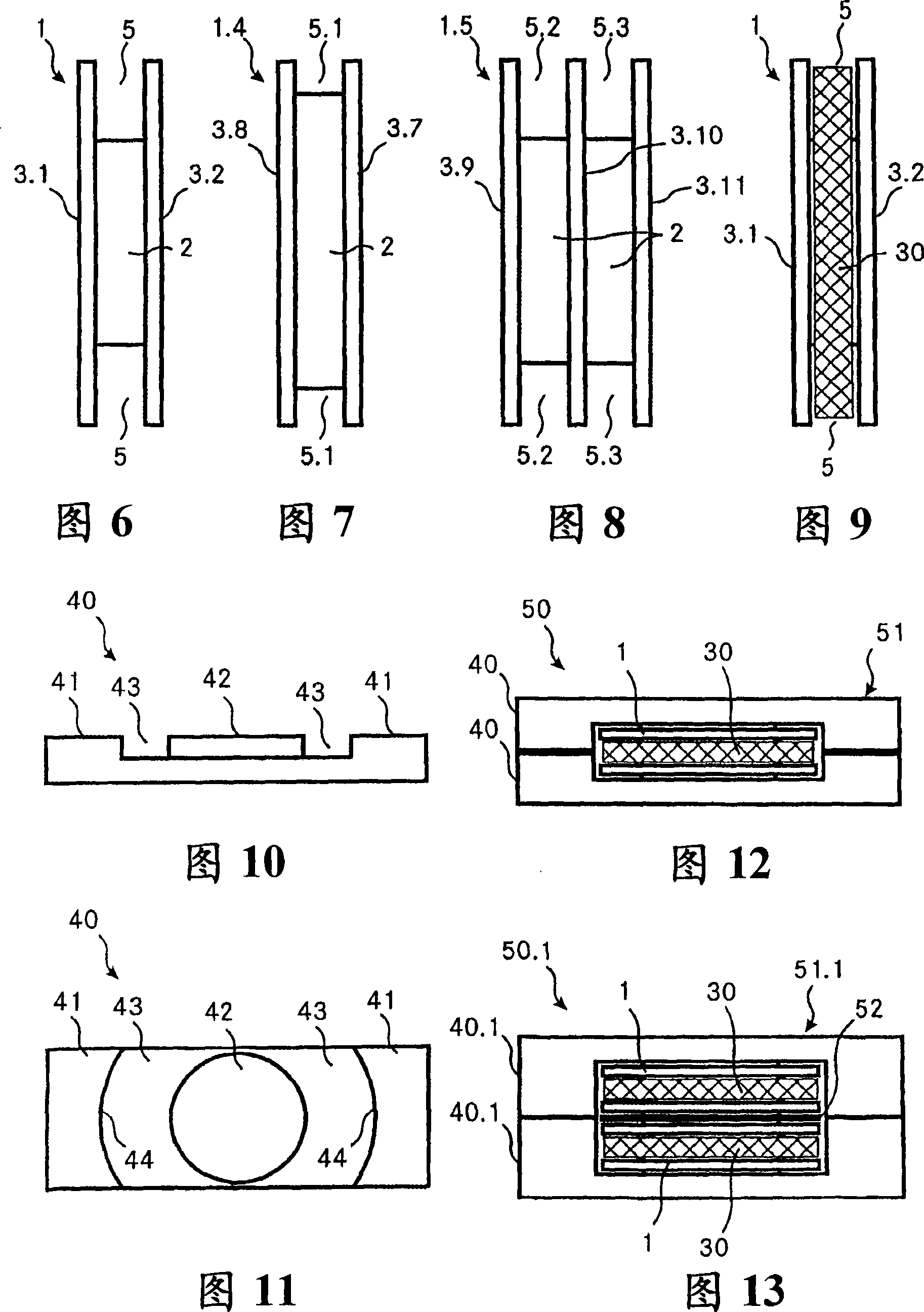

[0046] FIG. 1 shows a coil former 1 according to the invention. The coil former comprises a hollow cylindrical housing part 2 and two annular flange parts 3.1 and 3.2 at both ends of the housing part 2. The housing part 2 and the flange parts 3.1 and 3.2 are made of copper. The housing part 2 forms an opening 9 into which a magnetic core can be inserted. The outer surface of the housing part 2 and the inner side walls of the flange parts 3.1 and 3.2 form the winding chamber 5. On the right side of the coil former 1 (as shown), the coil former 1 comprises four terminals 6.1, 6.2, 6.3 and 6.4. Slit 7 separates housing part 2, flange parts 3.1 and 3.2 and terminals 6.1, 6.2, 6.3 and 6.4 to form current path 8 around opening 9. For example, a current traveling along the current path 8 in an anti-clockwise direction flows first through the terminals 6.1 and 6.2, then through the flange parts 3.1 and 3.2 and the housing part 2, and then through the terminals 6.3 and 6.4. The sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com