Sampling method of liquid metal and device thereof

A liquid metal and liquid technology, which is applied in the field of liquid metal sampling and devices, can solve the problems of inability to solve the interference of sampling metal oxidation analysis samples, no solution to analysis samples, inability to guarantee samples, etc., and achieves easy popularization, simple structure, The effect of high sampling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

[0027] A specific implementation example 1 is given below: sampling of liquid aluminum alloy in a crucible.

[0028] Iron is an impurity in cast aluminum alloys. In order to find out the content of iron in the depth direction of the crucible, it is necessary to take samples at different depths of the crucible. In this example, the depth of the liquid aluminum alloy in the crucible is 800 mm, and the alloy composition is Si: 7%, Mg: 0.3%, and the rest is Al. It is desired to measure the content (percentage by weight) of iron along the depth direction after being kept at 730° C. for 10 hours.

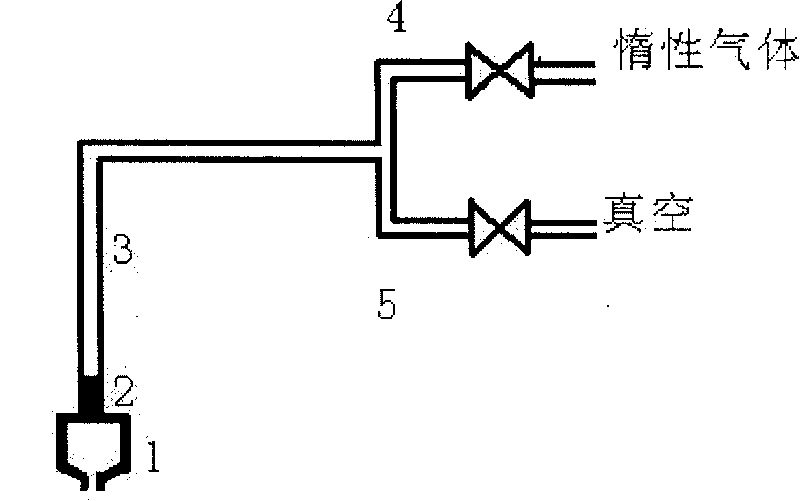

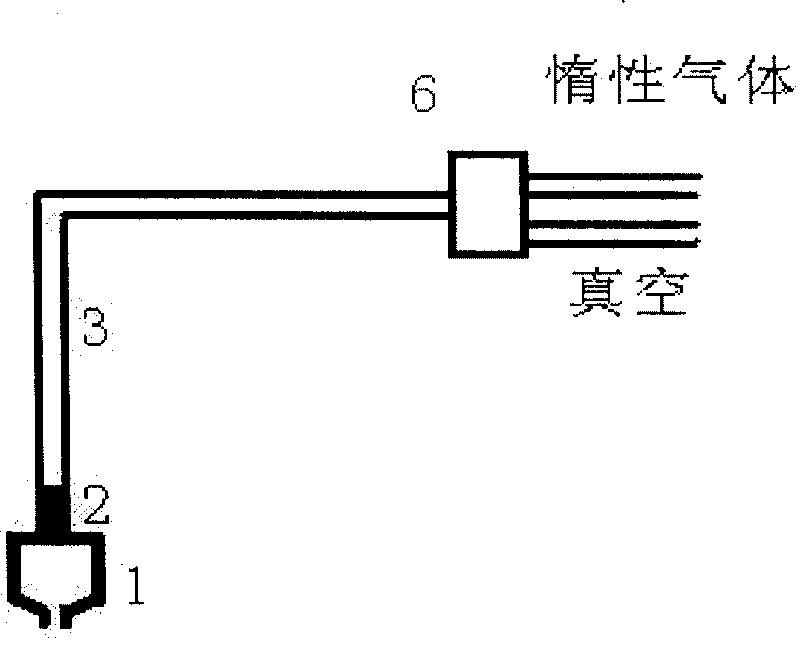

[0029] Sampling is carried out according to the following steps (refer to figure 1 ):

[0030] 1. Heat the sampling chamber 1 to 750°C. (Reason: In order to prevent the liquid aluminum alloy from being affected after the sampling chamber is immersed in the crucible.)

[0031] 2. Open the inert gas valve 4 and adjust the flow rate so that a small amount of nitrogen gas is blown out fro...

Embodiment example 2

[0039] Implementation Case 2: Sampling of density distribution of coatings for precision casting.

[0040] Coatings for precision casting are made by mixing powdery refractory materials, silica sol solution and a small amount of defoamer. The prepared coating should have uniform density. However, in the process of use, powder settlement will inevitably occur, so the coating on the upper part of the container is thinner and less dense; while the coating on the lower part of the container is thicker and denser. As a result, the process is unstable and affects product quality. In order to control the process, it is necessary to know the change of the coating density of each part of the container with time, and it is necessary to take samples for testing. The formula of coating is as follows (percentage by weight):

[0041] Silica sol: 22%; zircon powder: 78% plus a small amount of wetting agent and defoamer according to the situation.

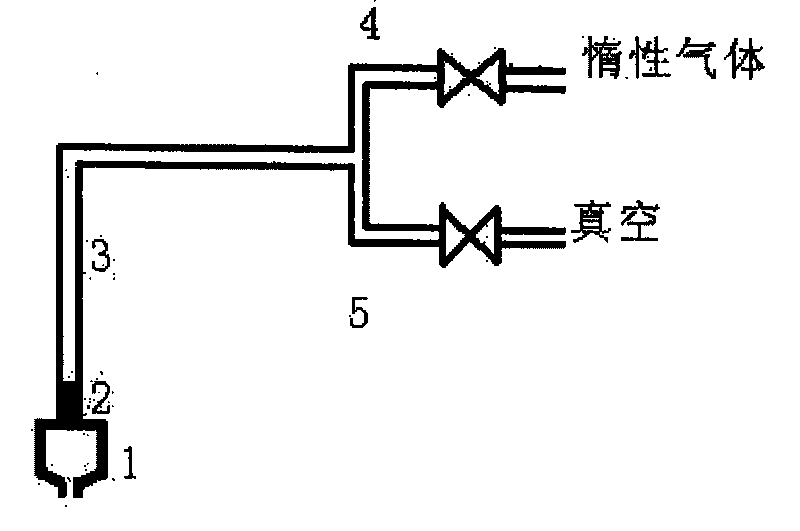

[0042] Sampling is carried out accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com