Suction chamber for a manifold for water jet treatment of fabrics

A suction chamber and textile technology, applied in the field of suction chambers, can solve the problems that the spray water cannot be sucked away, and the spray water is not sufficiently removed, and achieves the effect of strong air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

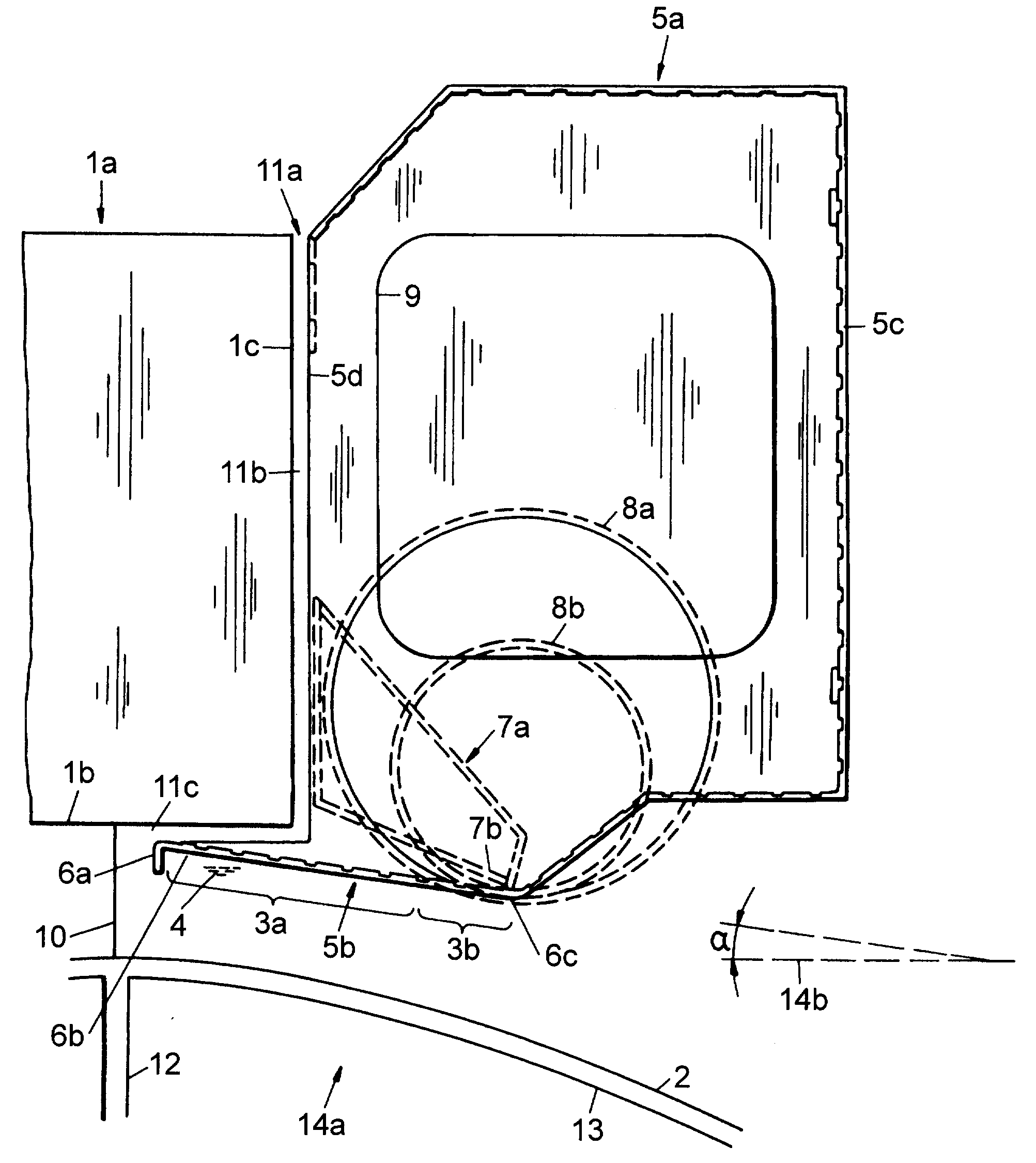

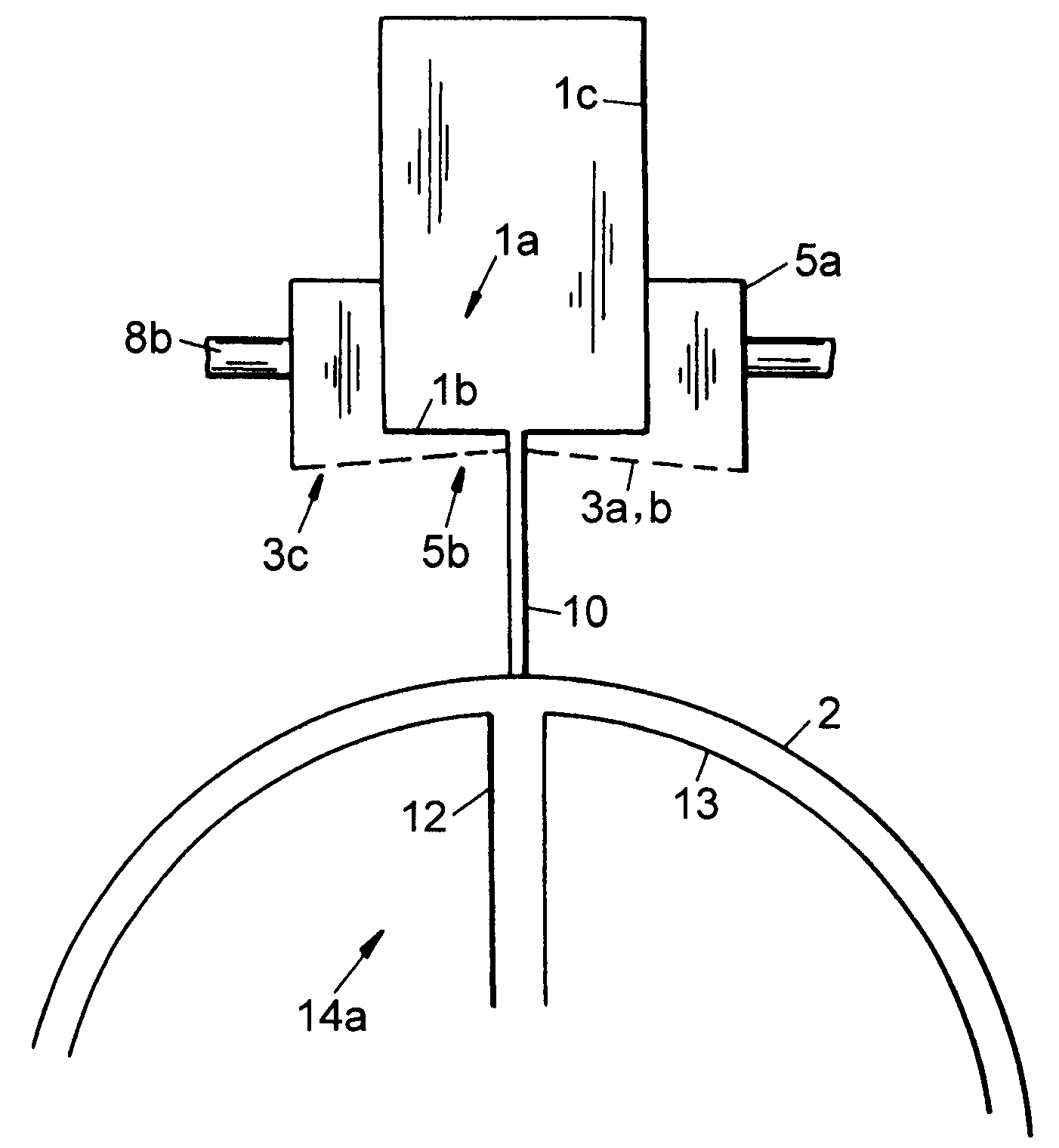

[0032] exist figure 1 , the water beam, denoted 1a, from which a water jet 10 emerges through nozzle openings (not shown in the schematic diagram) and strikes the fabric carrier 13 conveyed through the screen drum or screen drum 14a Textile, mesh or non-woven 2. At the same time, most of the water is led out through the drainage device 12 of the screen drum 14a.

[0033] In the region of the water beam 1a is a suction device or suction chamber 5a which has, on its underside 5b, inclined porous suction surfaces 3a,b with openings 3c so that the water The spray water formed when the jet 10 occurs on the textile, mesh or non-woven fabric 2 is guided to the lower side 5b of the suction chamber and can then be sucked off sufficiently by the suction chamber 5a. Therefore, it is possible to avoid water droplets appearing on the underside of the water beam 1 a and no longer drip onto the woven fabric, mesh fabric or non-woven fabric 2 .

[0034]In this embodiment, the suction chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com