Noise-insulating cladding for a panelled housing

A technology of sound attenuation and casing, which is applied in the direction of sound-generating equipment, electrical components, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

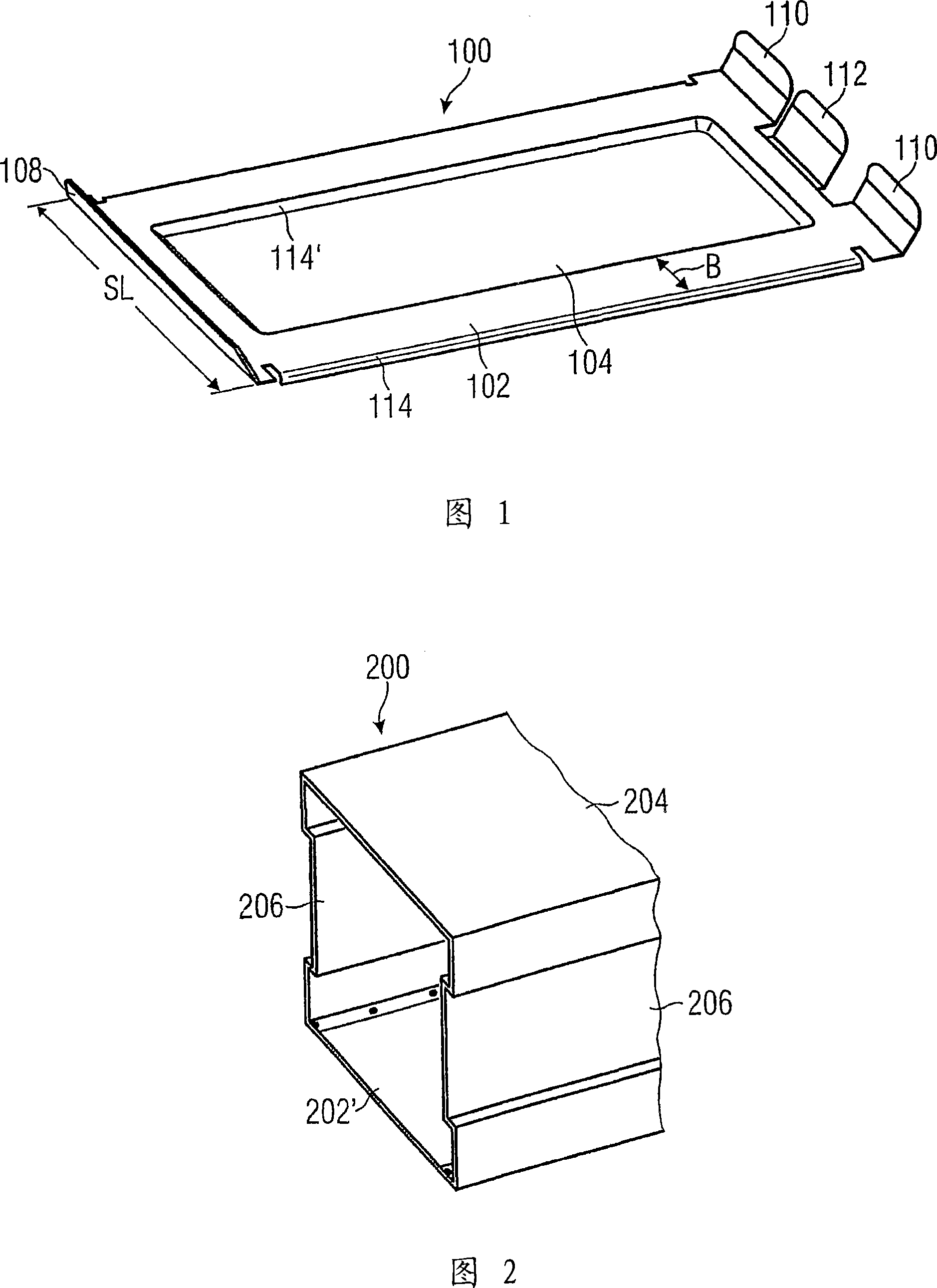

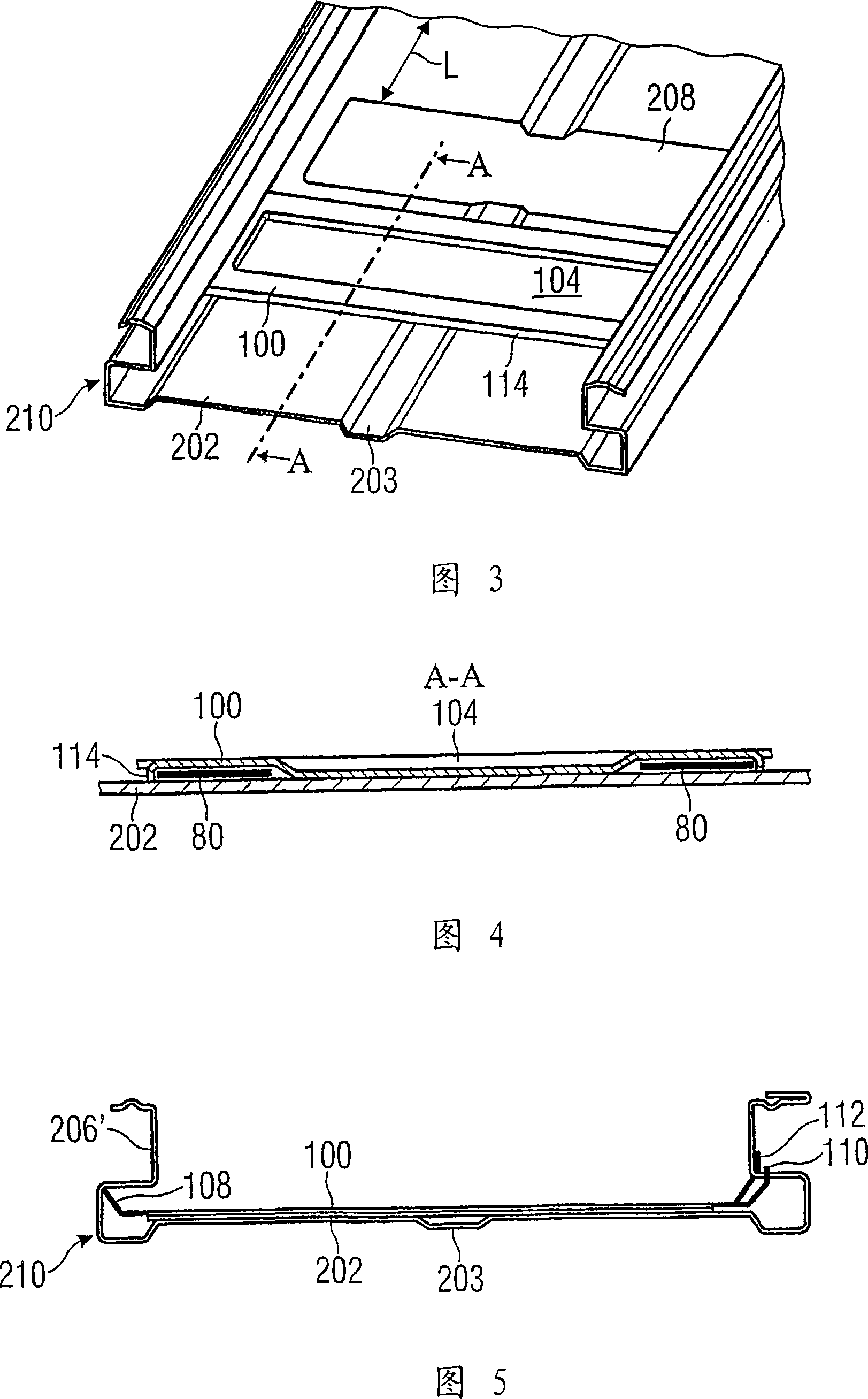

[0027] Figure 1 shows a frame-shaped lining element 100, preferably made of sheet metal. On the left side of the figure, the lining element 100 has a curved support flange 108, and on the right side there are three upward spring bars 110 to 112. As can also be seen from FIG. 5, the support bar and the spring bar are used to hook with the crimp 210, thereby generating pressure in the direction toward the bottom surface (202, 202') of the housing 200. The middle spring bar 112 on the right side bends upwards steeper than the other two spring bars 110. With this steeper position, the middle spring bar 112 contacts the side wall 206, thereby being used for tensioning in a direction transverse to the housing.

[0028] The material strip is constructed in a frame shape, where the frame width B is approximately one-fifth of the elongated side SL of the material strip. The frame can be designed as a material cut or stamped in the shape of the window 104. The typical size of the material s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com