Multi-stage piston compressor having an outer cooling air conduction system

A technology for cooling air and compressors, which is applied to the components of pumping devices for elastic fluids, multi-stage pumps, liquid variable displacement machines, etc., which can solve the problem of cooling air disappearing and achieve the effect of reducing sound radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

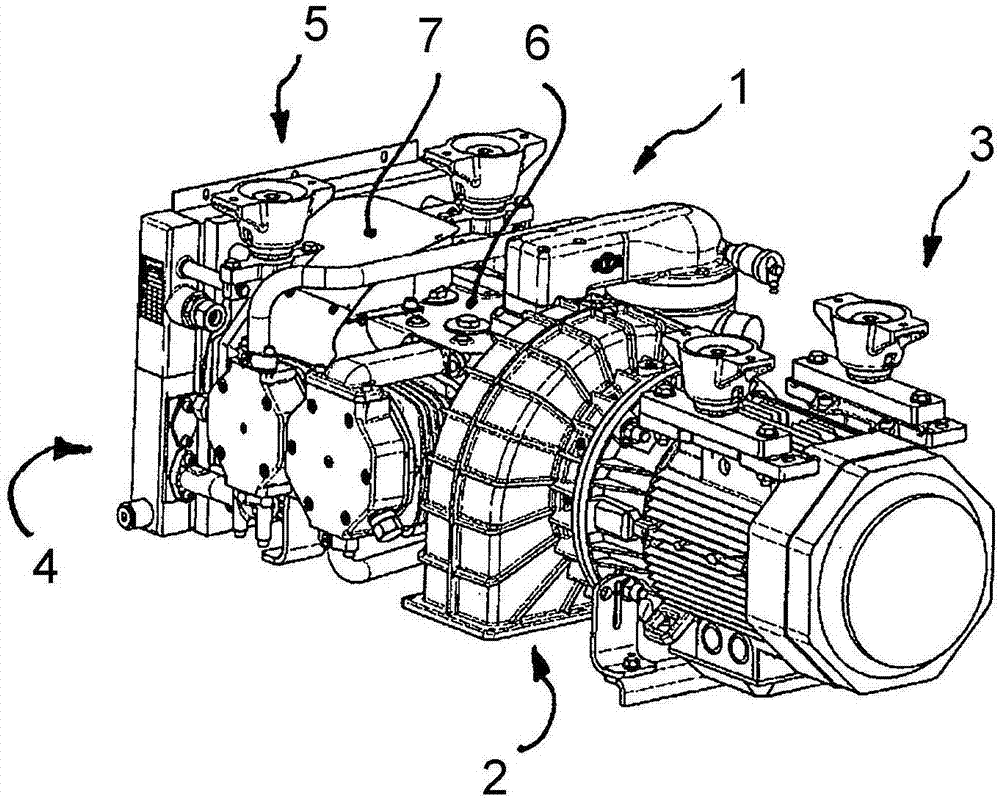

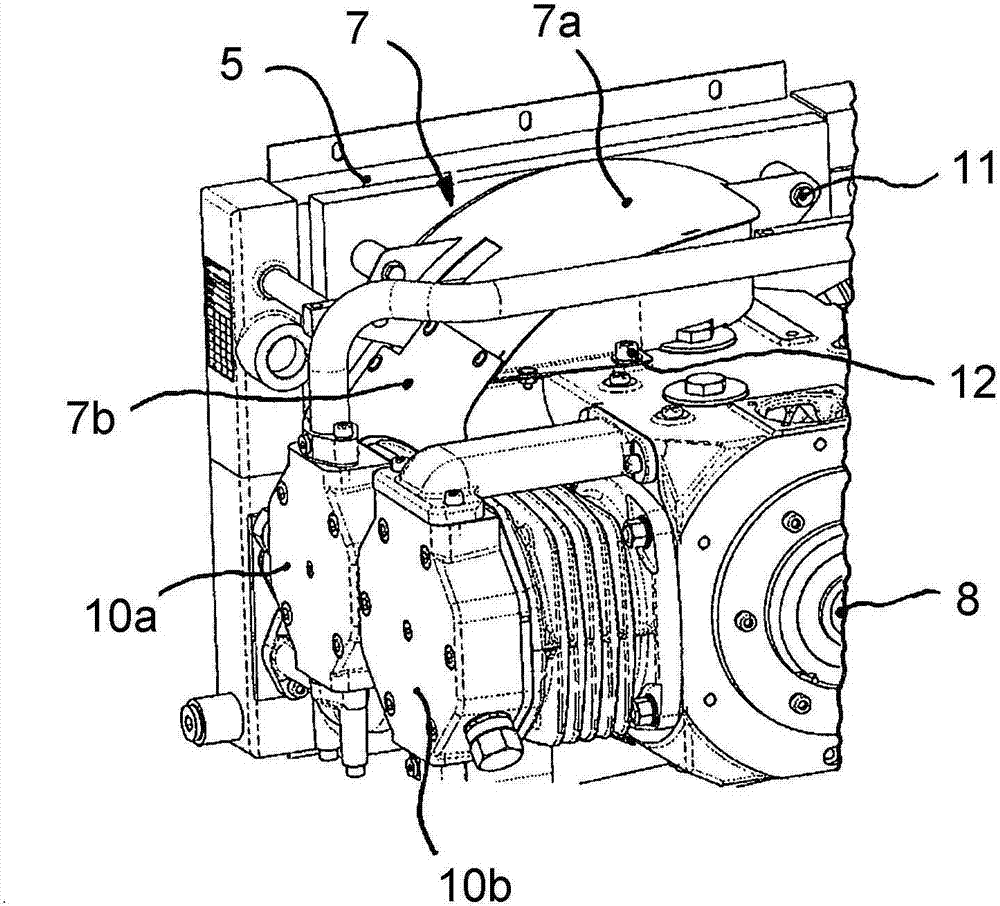

[0024] according to figure 1 , the multi-stage piston compressor mainly comprises a compressor unit 1, a motor unit 3 in the form of an electric motor is flanged to the first end side 2 of the compressor unit, and a cooler unit 5 is installed at the opposite end on side 4. The cooler unit 5 serves to cool the compressed air flow heated by the compression inside the compressor unit 1 by means of an axial fan wheel (not visible here) for generating cooling air along the compressor unit 1 1 flows externally. For external cooling air guidance in the region of the compressor unit 1 , an air guidance housing 7 extending partially radially around the crankcase 6 in an arc is provided.

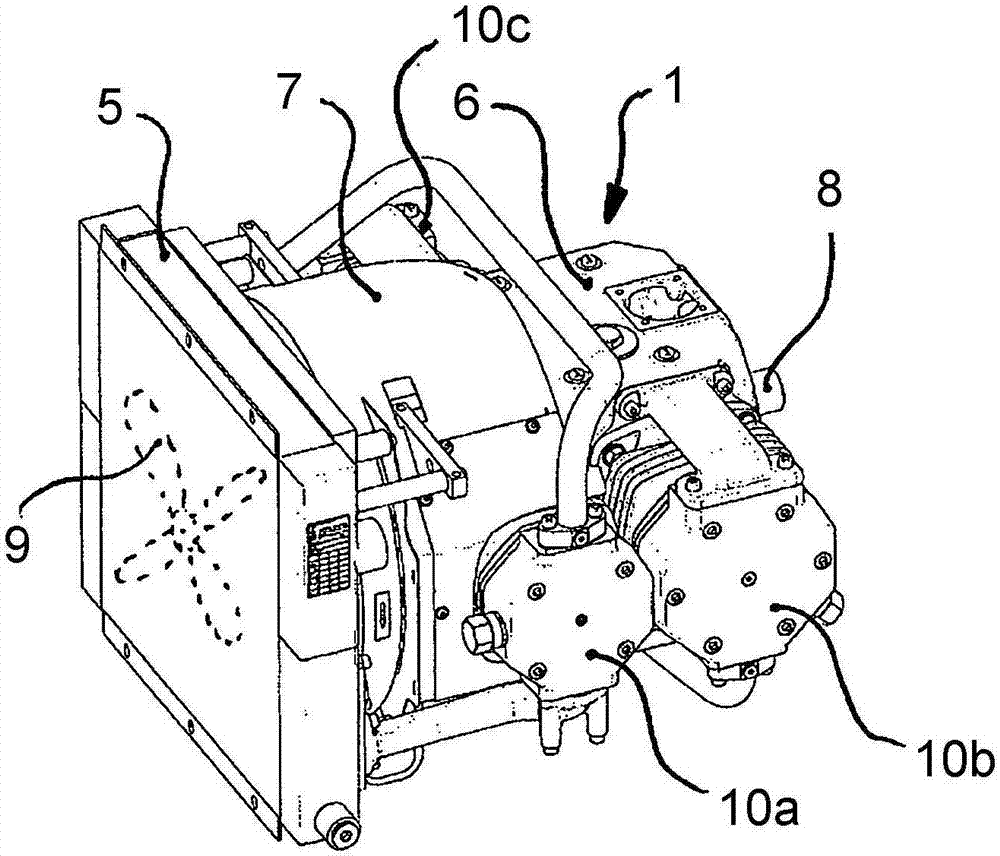

[0025] according to figure 2 , the crankshaft 8 mounted rotatably in the crankcase 6 (which can be seen here with the motor unit disassembled) drives the axial flow of the cooler unit 5 , shown schematically by shaded outline. Fan impeller 9. The axial fan impeller 9 generates an air flow along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com