A milling tool, a cutting insert for milling tool as well as a solid milling tool

A blade and milling cutter technology, which is applied in the field of milling cutters, blades for milling cutters and integral blades, can solve the problems of limiting the service life of milling cutters and adverse effects on cutting edge strength, and achieve improved chip removal speed and high chip removal speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

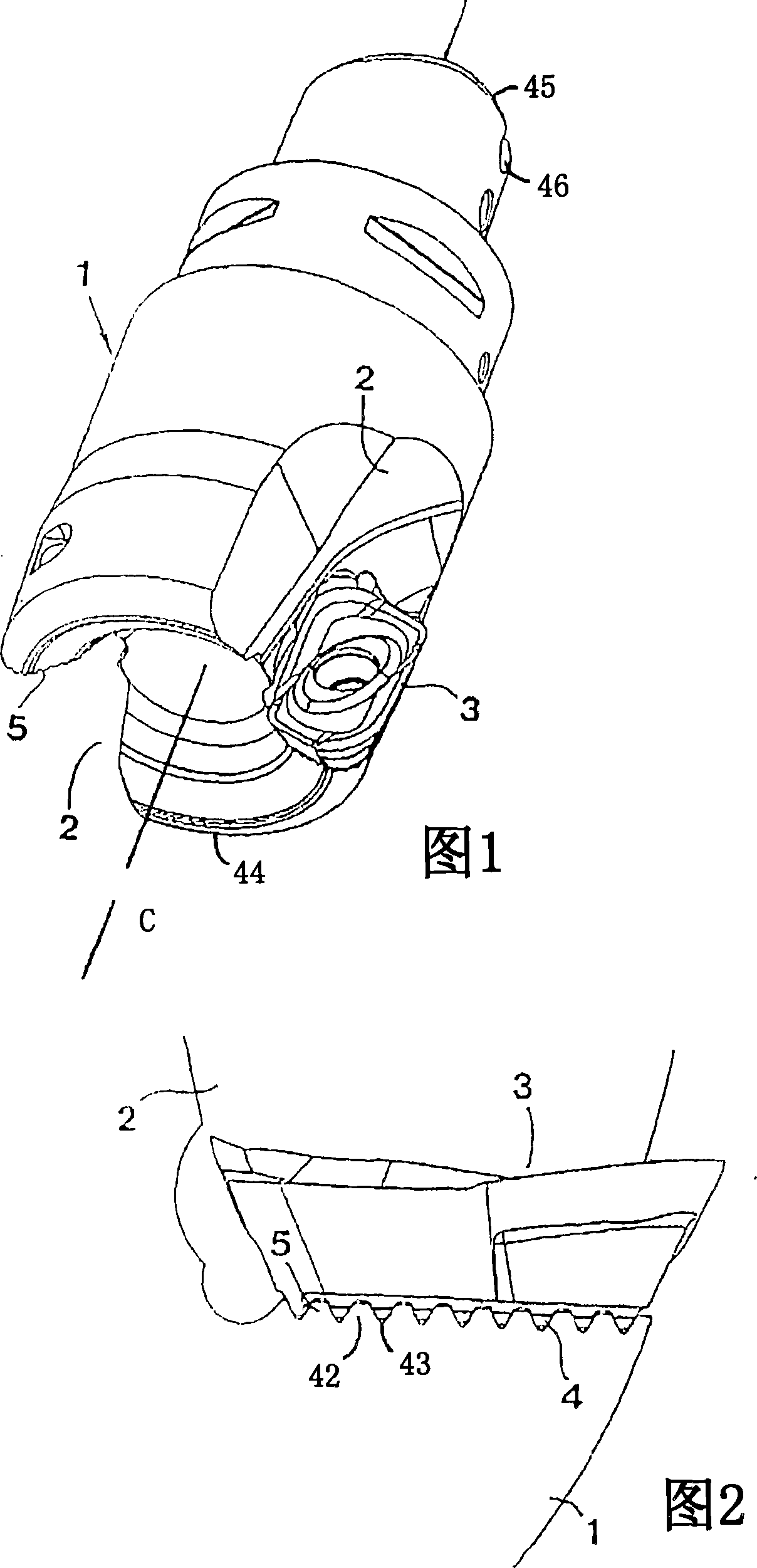

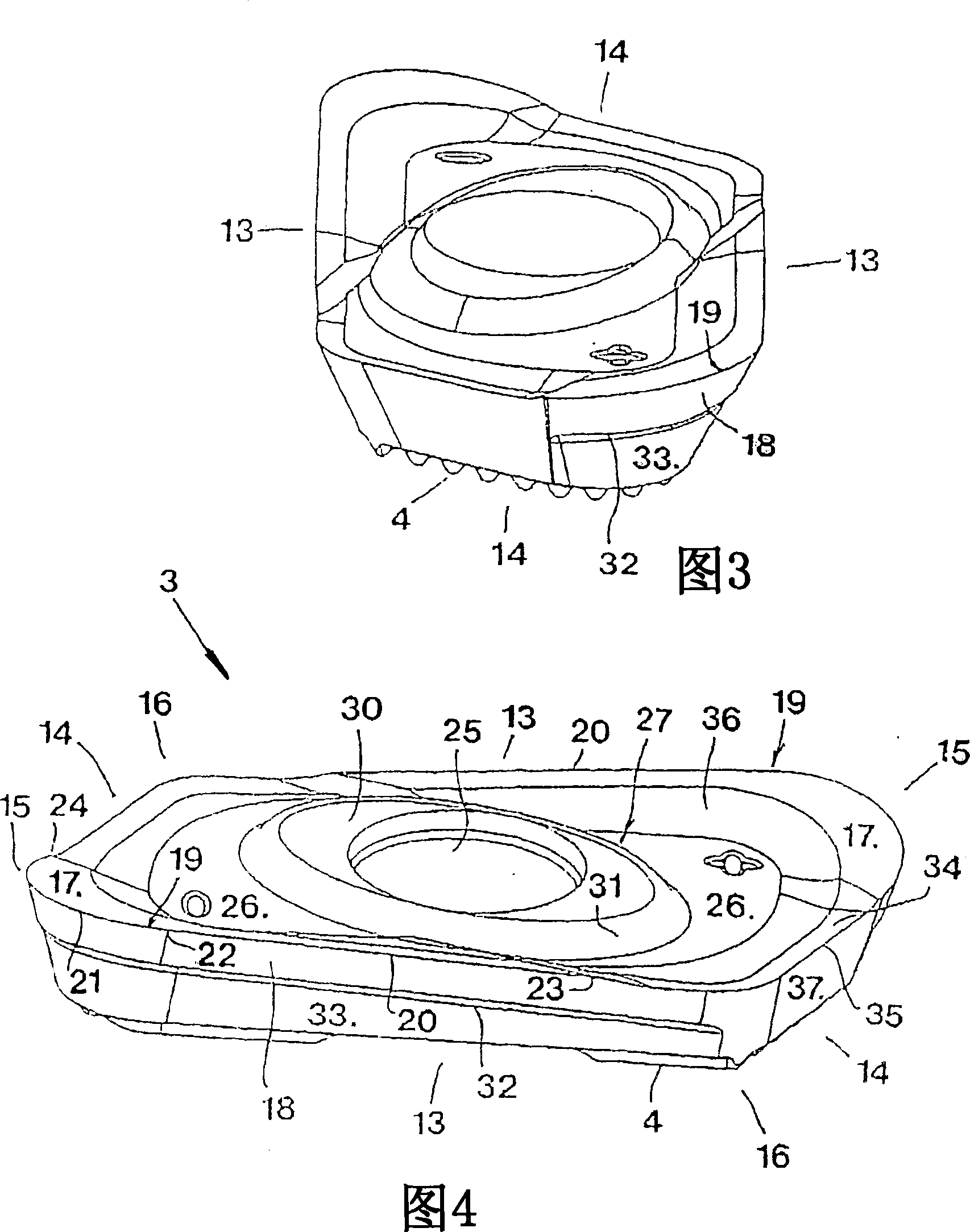

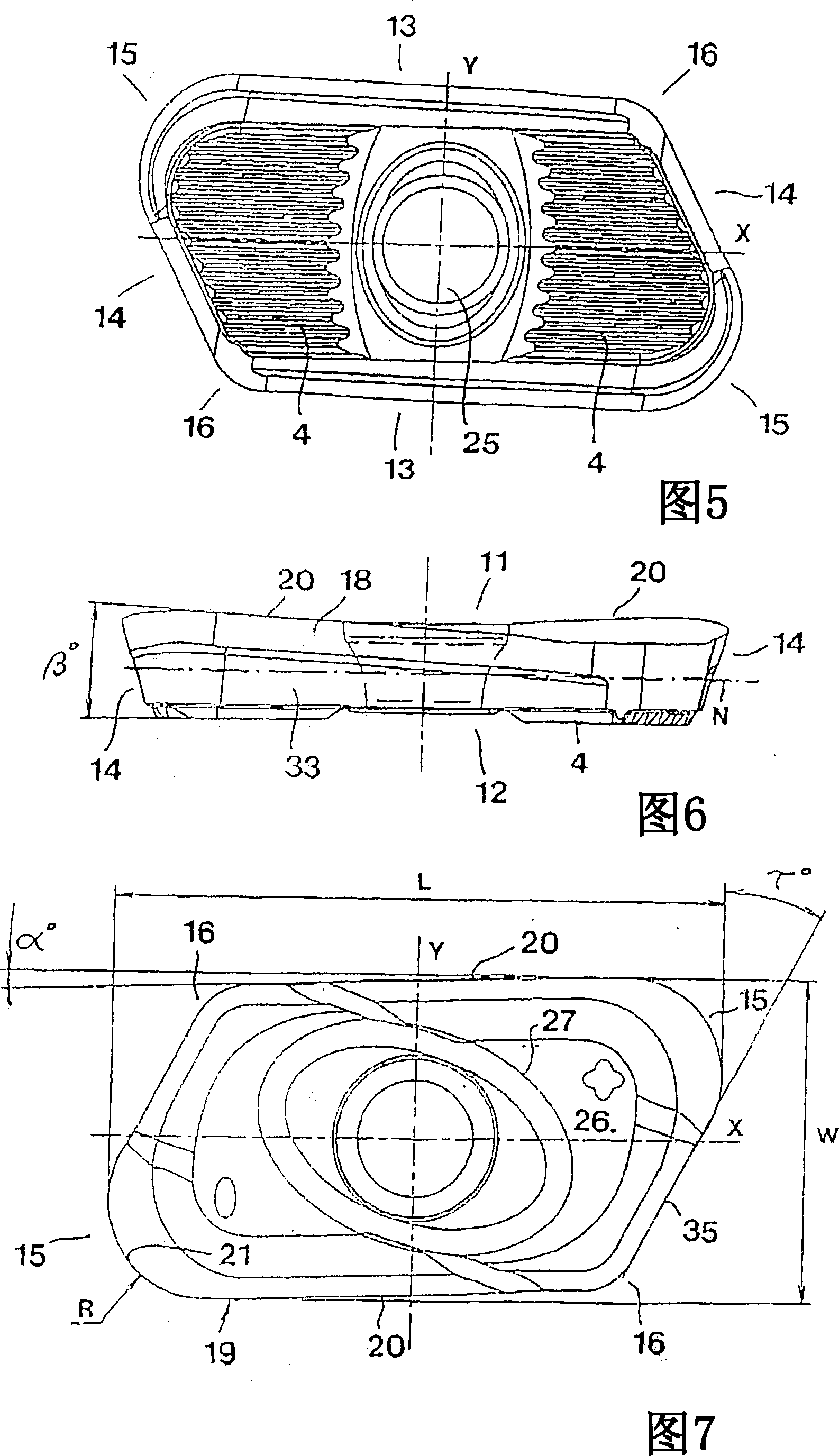

[0024] In FIG. 1 , a milling cutter according to a preferred embodiment of the invention is shown, comprising a body 1 having a rotationally symmetrical basic shape, the body 1 having a front end surface 44 and a rear end surface 45 comprising a The means attached to the drive spindle, ie the recessed portion 46. The body can rotate around the geometric central axis C. Two chip channels 2 are formed on the envelope surface of the body 1 . In one of the chip channels, a milling insert 3 according to an embodiment of the invention is installed. In FIG. 2 , it can be seen that the blade 3 has at the bottom side at least one connection surface 4 , of the type comprising a plurality of parallel ridges spaced apart via grooves, the ridges having a conical shape in cross-section. This connection surface is intended to cooperate with a similar connection surface 5 provided by the ridge, which is arranged in the body 1 and forms an insert seat 5 in the chip channel 2 . It should be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com