Intelligent liquid level sensor and measuring method thereof

A liquid level sensor and sensor technology, which is applied in the field of sensors, can solve the problems of not being able to automatically adapt to changes in ambient temperature, humidity, and medium composition, and achieve the effects of improving self-adaptive capabilities, simple methods, and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

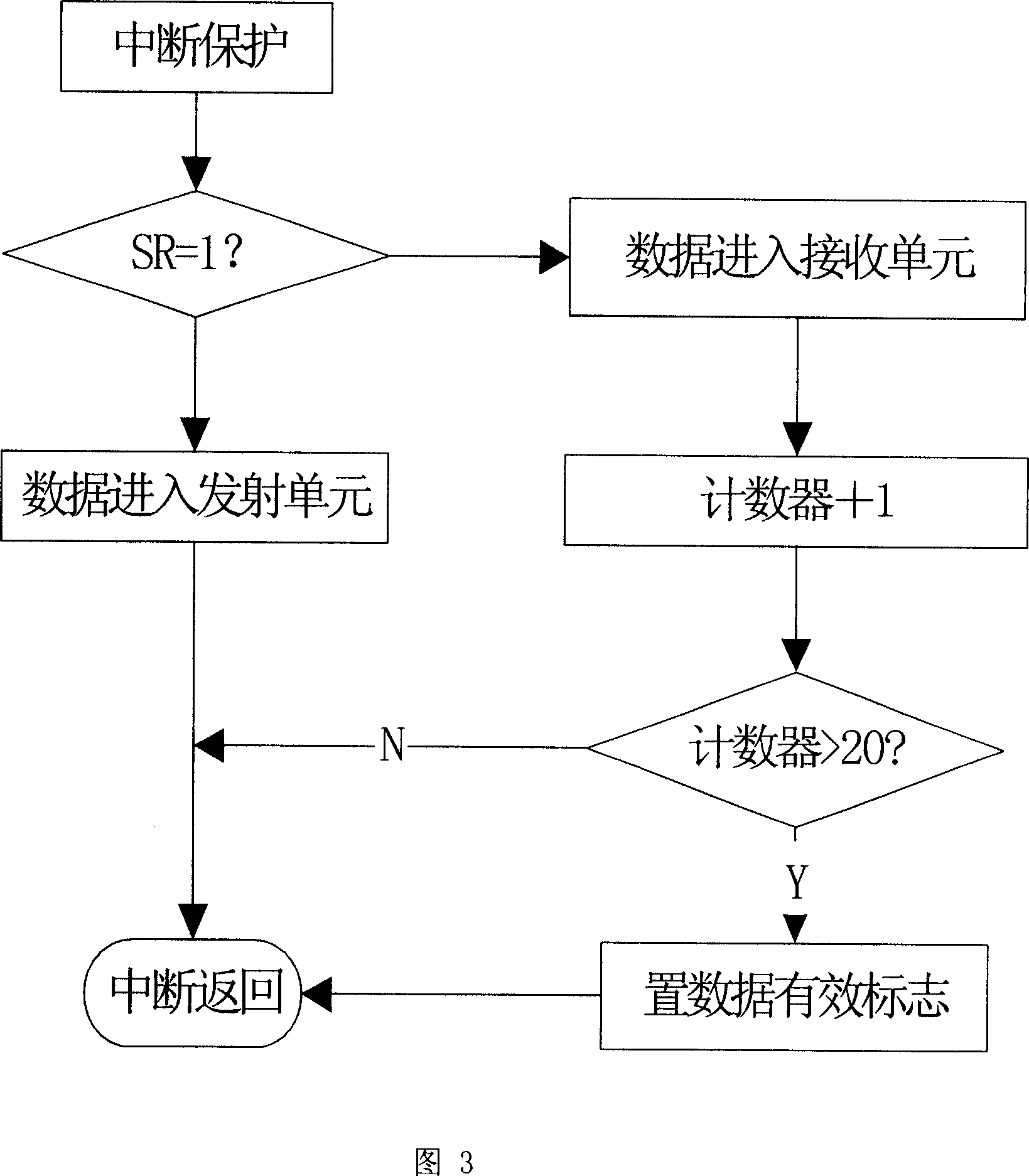

Image

Examples

Embodiment 1

[0041] Example 1. Intelligent liquid level sensor

[0042] See Fig. 1, the intelligent liquid level sensor of this implementation example comprises the distance measuring sensor 4 that two ultrasonic transmitting sensors and one ultrasonic receiving sensor constitute; Microcontroller unit 1 and CAN bus communication unit 3 behind the signal unit.

[0043]See Fig. 5, the model of the microcontroller 1-1 labeled as U1 is PIC18F258 single-chip microcomputer, and this single-chip microcomputer is integrated with 32KB of Flash program memory, 1536B of SRAM and 256B of EEPROM, and has the incomparable advantages of many other single-chip microcomputers: First of all, it adopts the Harvard dual-bus structure, and the data and instruction transmission buses are completely separated, so that the program and data can be accessed at the same time, which improves the data throughput. Secondly, it adopts a two-stage pipeline structure, which can fetch the next instruction while executing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com