Single-point horizontal screw unloading filter centrifugal machine

A horizontal screw and screw unloading technology, which is applied to centrifuges and centrifuges with rotating drums, etc., can solve the problems of feeding pipe occupation, complex structure, difficulty in installation, maintenance and replacement, etc., and achieve replacement and Easy maintenance, avoid complex structure, improve separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

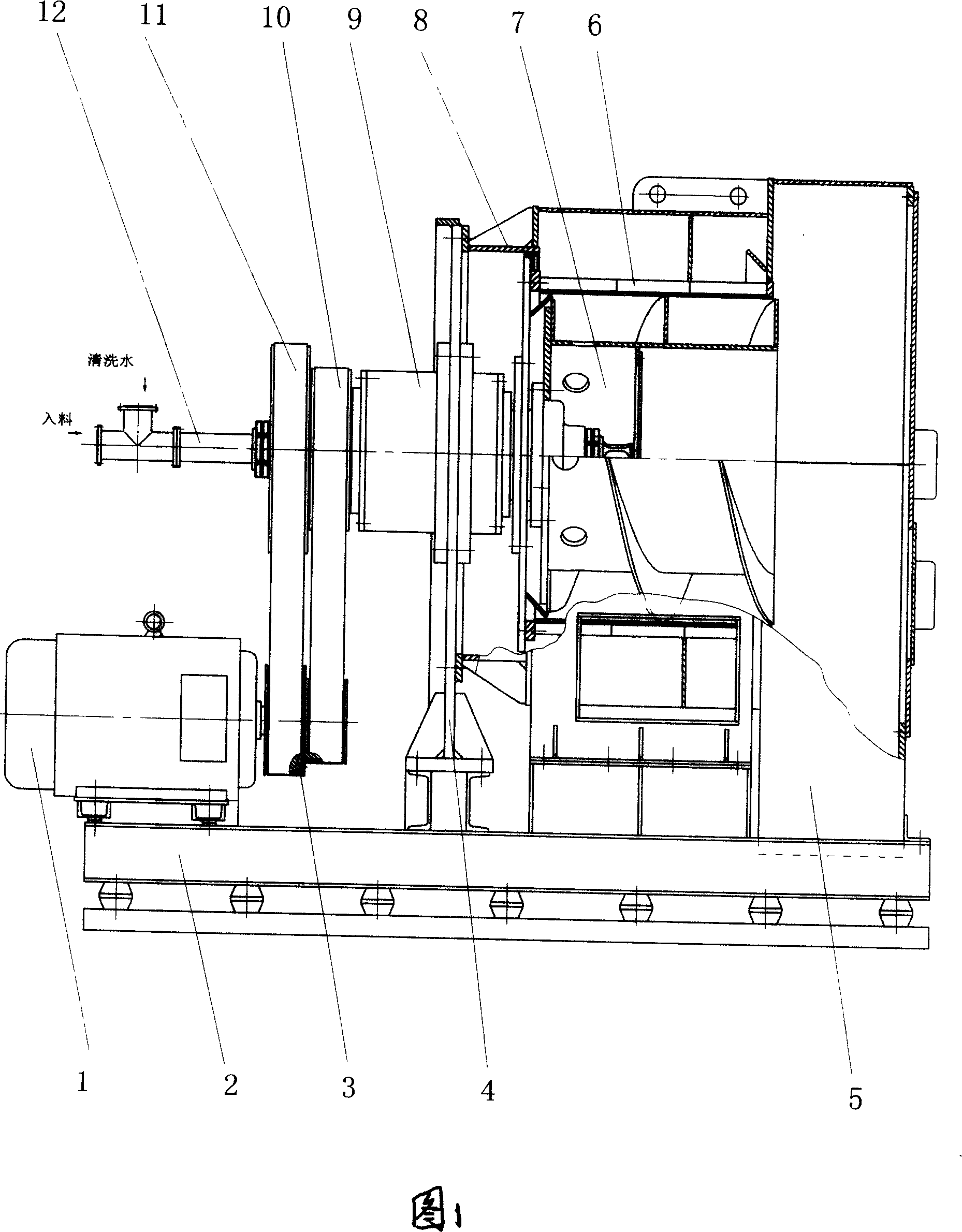

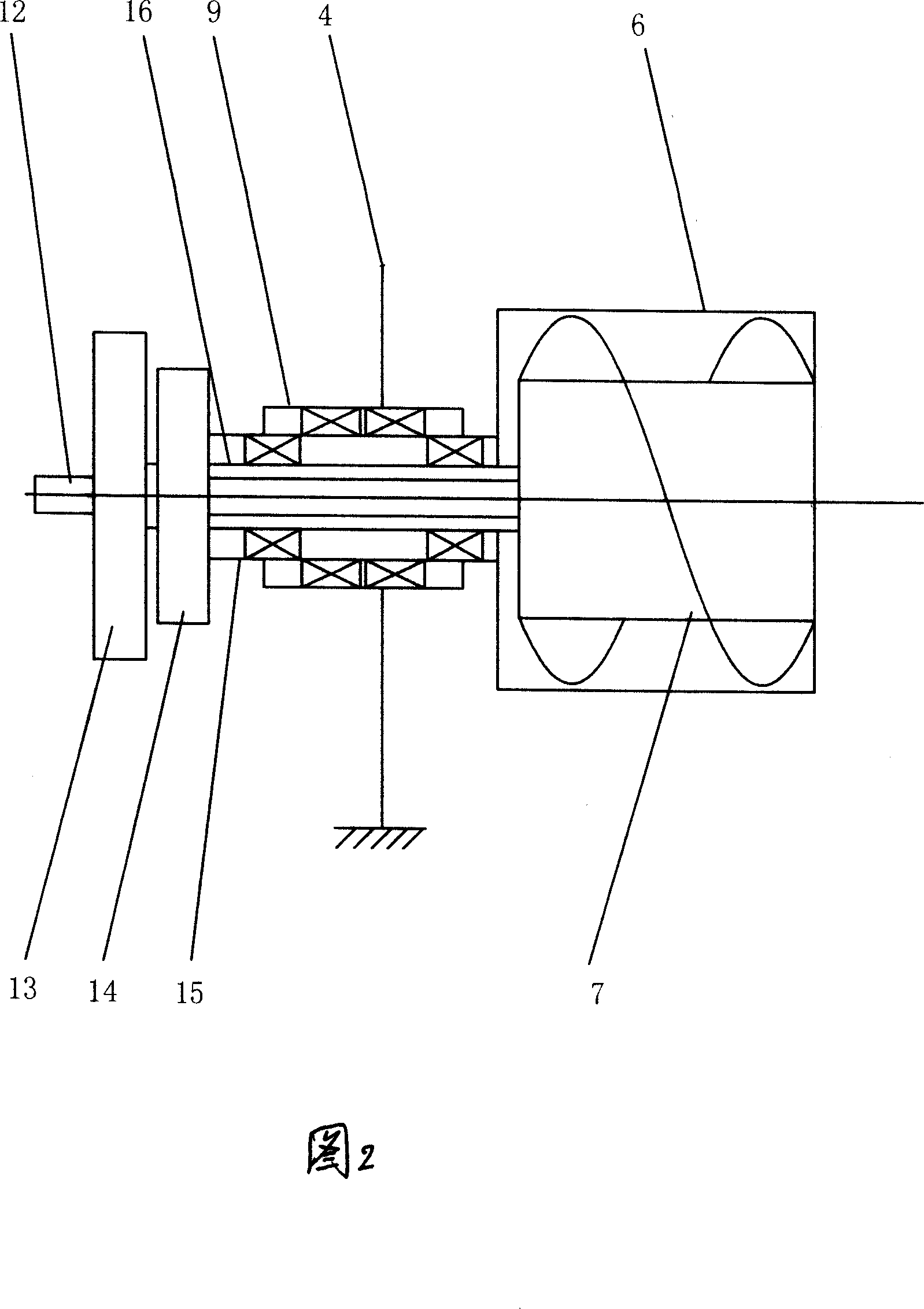

[0012] As shown in Figures 1 and 2, the motor 1 is placed directly below the center of rotation of the screen basket 6, and is fixed on the base 2 through the motor base. Two active synchronous wheels 3 are installed on the motor shaft, and the active synchronous wheel 3 passes through the synchronous belt. 10 and 11 respectively drive the driven synchronous wheels 14 and 13 to provide a certain speed and slip; the driven synchronous wheel 14 is installed on the hollow shaft 15 of the screen basket, and the other end of the hollow shaft 15 of the screen basket is installed with a cylindrical screen basket 6. The driven synchronous wheel 13 is installed on the hollow shaft 16 of the screw unloader, and the other end of the hollow shaft 16 of the screw unloader is installed with the screw unloader 7; the screen basket shaft 15 passes through the bearing chamber 9, and the screw unloader The hollow shaft 16 of the feeder passes through the hollow shaft 15 of the sieve basket, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com